Carbon dioxide curing method

A technology of carbon dioxide and solidification method, which is applied in the field of environmental engineering, can solve the problems of encroaching on land resources, increasing the operating burden of enterprises, large construction funds and operating management costs, etc., and achieves good impurity removal effect, high activation index, and high carbon sequestration rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A carbon dioxide solidification method, the steps are: taking modified phosphogypsum, adding ammonia water (concentration of 25wt%) and deionized water to mix, feeding 0.2L / min of carbon dioxide for carbonation treatment, and the conditions are that the temperature is 60°C and the time is 60min, The carbonation product is obtained to realize the fixation of carbon dioxide; wherein, after the modified phosphogypsum is mixed with ammonia water and deionized water, the solid-liquid ratio is 1g:2mL; the dosage ratio of ammonia water and modified phosphogypsum is n(N): n(S) = 2:1.

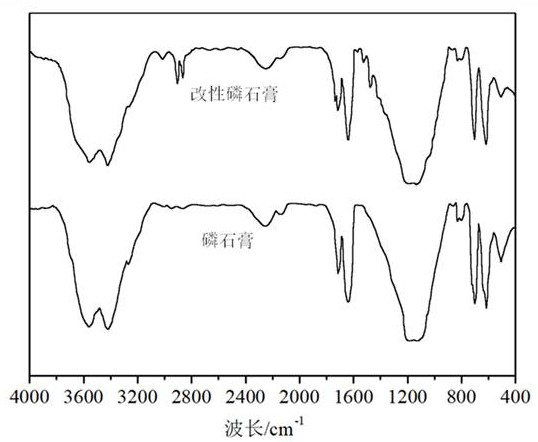

[0039] The preparation method of modified phosphogypsum includes: after pretreatment of the phosphogypsum, adding it to a brommethamine solution with a concentration of 1g / L (the mass-volume ratio of the phosphogypsum and the brommethamine solution is: 1g:90mL ), at a temperature of 25 °C, after fully stirring for 2 hours, filtered, washed, and dried to obtain modified phosphogypsum.

[0040] Th...

Embodiment 2

[0045]The difference between a carbon dioxide solidification method and Example 1: after the modified phosphogypsum is mixed with ammonia water and deionized water, the solid-liquid ratio is 1g:4mL; the dosage ratio of ammonia water and modified phosphogypsum is n(N):n( S) = 2.5:1.

[0046] The difference between the preparation method of modified phosphogypsum and Example 1: the mass-volume ratio of phosphogypsum and brommethamine solution is: 1g:110mL.

[0047] The difference between the pretreatment method of phosphogypsum and Example 1: the mass ratio of phosphogypsum to the total amount of coupling agent is: 1:15; the mass ratio of sulfuric acid solution to alkyl diphenyl phosphate is: 1:0.6.

Embodiment 3

[0049] The difference between a carbon dioxide curing method and Example 1: after the modified phosphogypsum is mixed with ammonia water and deionized water, the solid-liquid ratio is 1g:3mL; the dosage ratio of ammonia water and modified phosphogypsum is n(N):n( S) = 2.2:1.

[0050] The difference between the preparation method of modified phosphogypsum and Example 1: the mass-volume ratio of phosphogypsum and brommethamine solution is: 1g:95mL.

[0051] The difference between the pretreatment method of phosphogypsum and Example 1: the mass ratio of phosphogypsum to the total amount of coupling agent is: 1:13; the mass ratio of sulfuric acid solution to alkyl diphenyl phosphate is: 1:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com