Silicon-carbon negative electrode material with porous surface and tiny hollow spheres and preparation method of silicon-carbon negative electrode material

A surface porous, negative electrode material technology, applied in electrode manufacturing, battery electrodes, structural parts, etc., can solve problems such as being unfavorable to industrial production, reducing the capacity of composite materials, unable to meet commercial high-energy power sources, etc., to improve safety and cycle. Longevity, improvement of volume expansion problem, effect suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

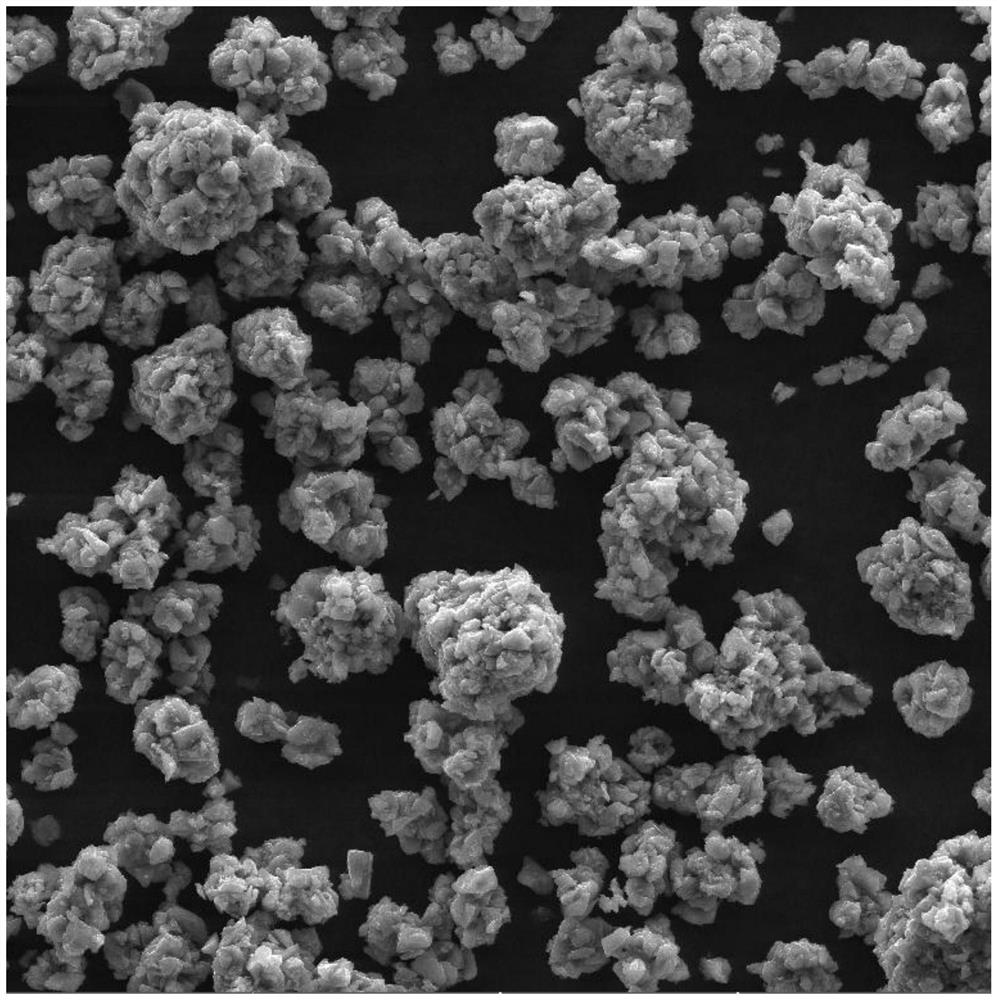

[0047] A surface-porous micro-hollow spherical silicon carbon negative electrode material comprises a silicon oxide hollow sphere, the surface of the sphere is a porous structure, the porosity is 1% to 20%, and the silicon oxide surface constituting the hollow sphere has a carbon coating layer;

[0048] Its preparation method mainly comprises the following steps:

[0049] Step 1. Slurry preparation:

[0050] Add silicon oxide powder into the polyvinylidene chloride emulsion, and then put it into the HY-DLH149H vacuum planetary mixer for stirring and dispersing. The dispersion speed is 2000r / min, the revolution speed is 30r / min, and the dispersion time is 130min. 600mpa·s.

[0051] Among them, silicon oxide powder accounts for 60%wt, as the shell active material on the surface of the core material, the median particle size D50: 2um, the specific surface area is 4㎡ / g, the purity is ≥99.9%, and the first Coulomb efficiency is 75%. , the first discharge gram capacity is 1000mAh / ...

Embodiment 2

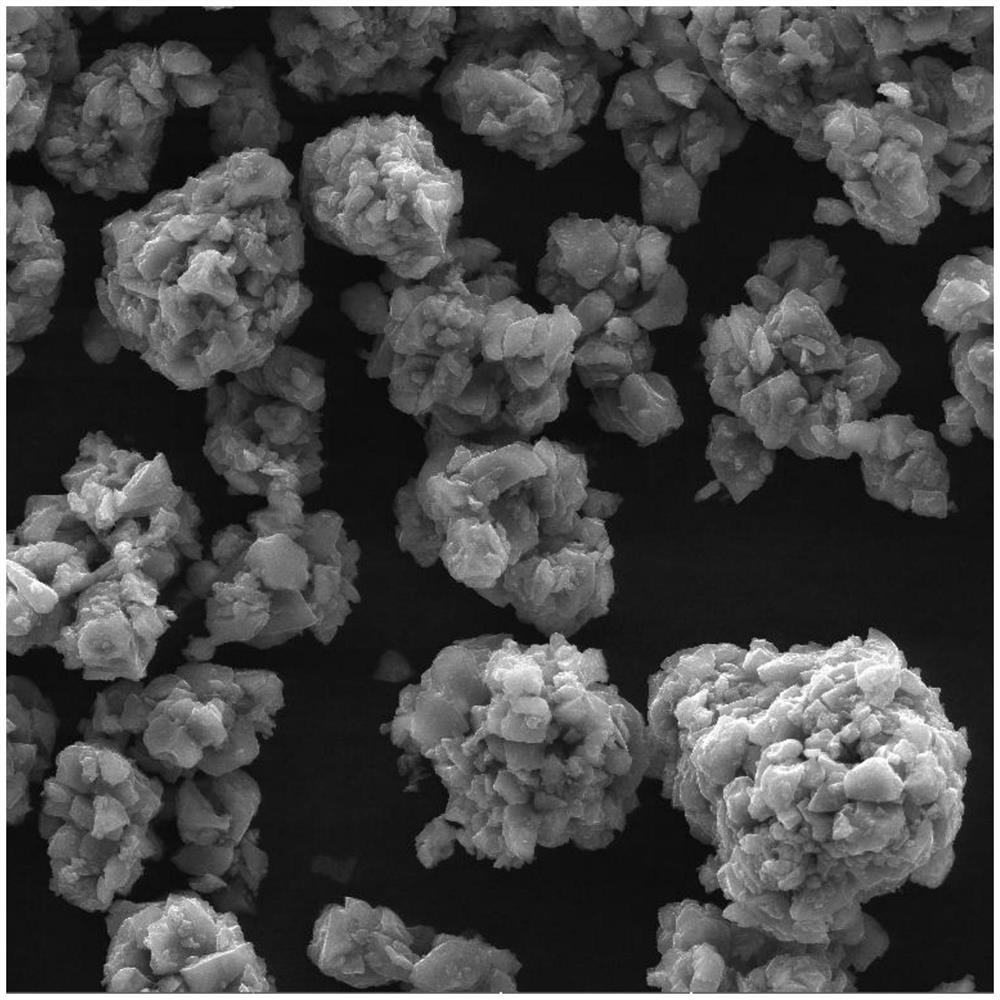

[0065] A surface-porous micro-hollow spherical silicon carbon negative electrode material comprises a silicon oxide hollow sphere, the surface of the sphere is a porous structure, the porosity is 1% to 20%, and the silicon oxide surface constituting the hollow sphere has a carbon coating layer;

[0066] Its preparation method mainly comprises the following steps:

[0067] Step 1. Slurry preparation:

[0068] Add silicon oxide powder into the polyvinylidene chloride emulsion, and then put it into a vacuum planetary mixer for stirring and dispersing.

[0069] Among them, silicon oxide powder accounts for 30%wt, as the shell active material on the surface of the core material, the median particle size D50: 4um, the specific surface area is 3㎡ / g, the purity is ≥99.9%, and the first Coulomb efficiency is 75%. , the first discharge gram capacity is 1400mAh / g, and the tap density is 0.9g / cm 3 ;

[0070] The polyvinylidene chloride emulsion is used as a material binder and a surfac...

Embodiment 3

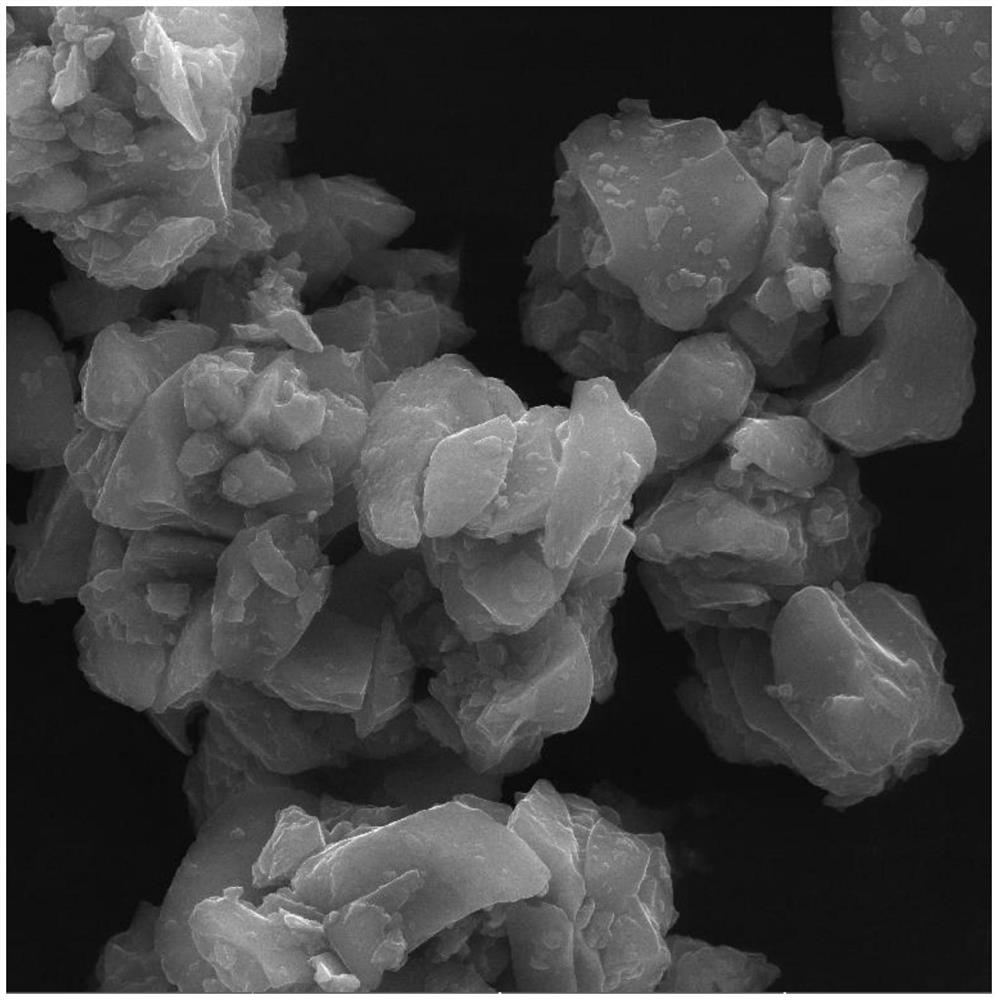

[0083] A surface-porous micro-hollow spherical silicon carbon negative electrode material comprises a silicon oxide hollow sphere, the surface of the sphere is a porous structure, the porosity is 1% to 20%, and the silicon oxide surface constituting the hollow sphere has a carbon coating layer;

[0084] Its preparation method mainly comprises the following steps:

[0085] Step 1. Slurry preparation:

[0086] Add silicon oxide powder into the polyvinylidene chloride emulsion, and then put it into a vacuum planetary mixer for stirring and dispersing.

[0087] Among them, silicon oxide powder accounts for 45%wt, as the shell active material on the surface of the core material, the median particle size D50: 10um, the specific surface area is 2.5㎡ / g, the purity is ≥99.9%, and the first Coulomb efficiency is 76%. , the first discharge gram capacity is 1600mAh / g, and the tap density is 1.0g / cm 3 ;

[0088] The polyvinylidene chloride emulsion is used as the material binder and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com