Silicon-based GaN HEMT heat dissipation enhanced packaging structure and preparation method thereof

A packaging structure, silicon-based technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problem of high difficulty in growing GaN epitaxial wafers on diamond substrates, and cannot solve heat accumulation and heat dissipation Complex structure and other issues to avoid heat accumulation effect, facilitate mass production and improve heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

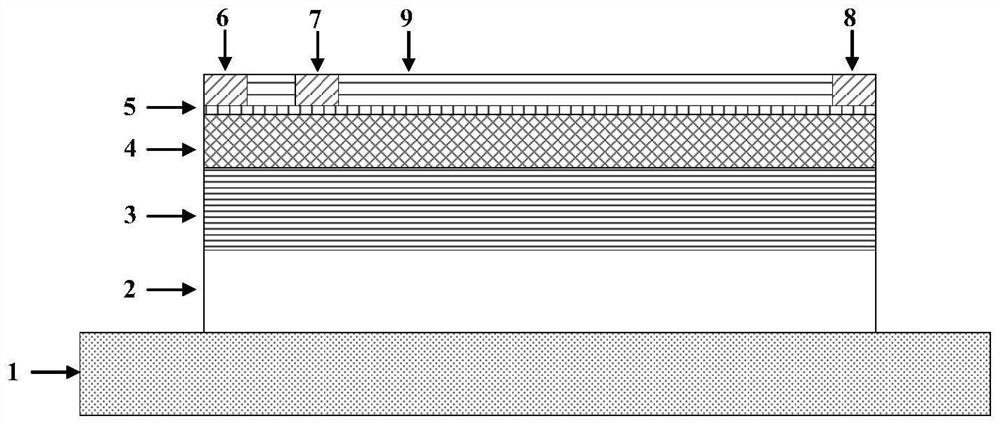

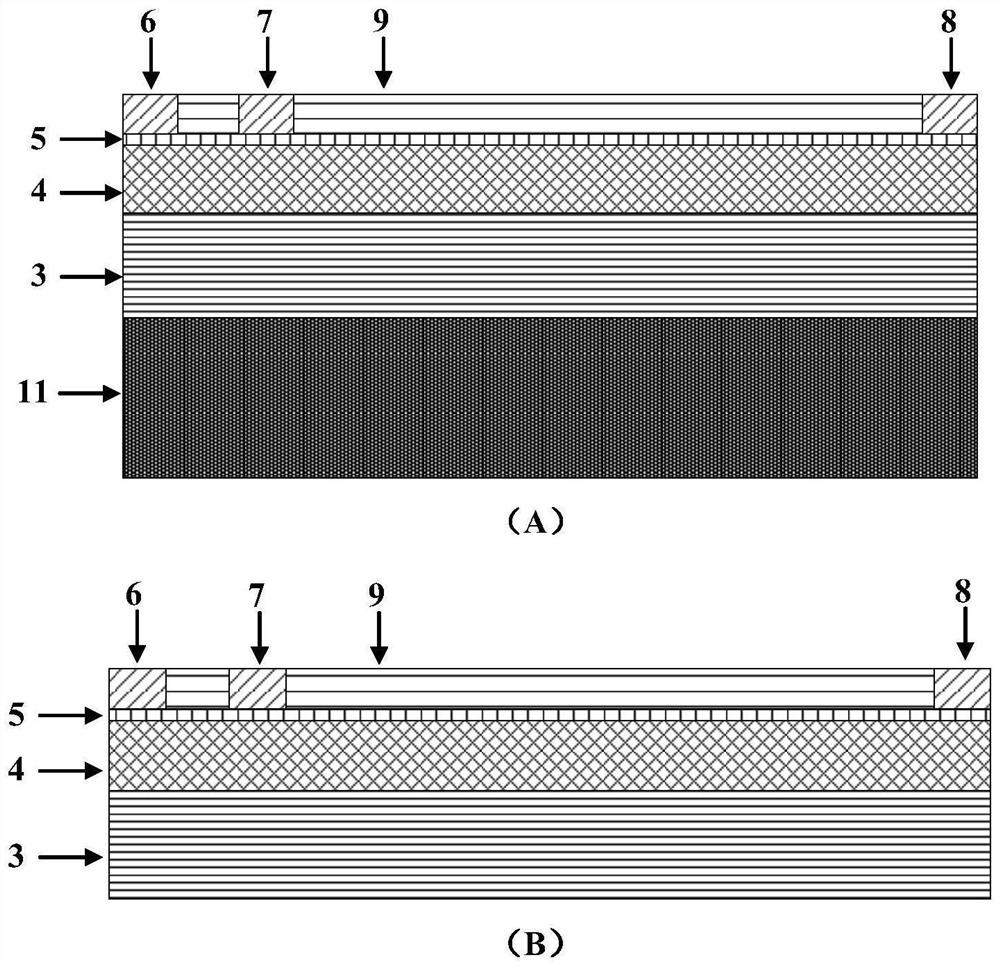

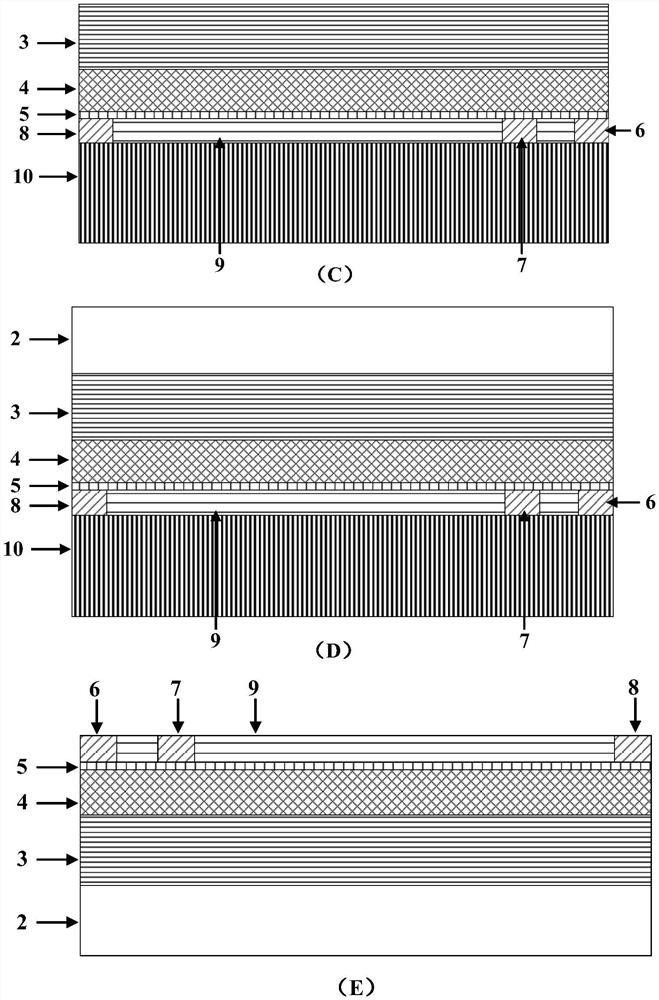

[0034] A silicon-based GaN HEMT (gallium nitride high electron mobility transistor) heat dissipation enhanced packaging structure is prepared by the following steps:

[0035] Step 1), cleaning the silicon substrate;

[0036] Step 2), on the silicon substrate, using metal organic chemical vapor deposition to sequentially epitaxially grow the GaN buffer layer, the GaN channel layer and the AlGaN barrier layer to obtain a silicon-based gallium nitride epitaxial wafer;

[0037] Step 3), using PECVD to coat the surface of the epitaxial wafer in step 2) with silicon nitride dielectric material, passivating the surface of the AlGaN barrier layer, reducing the interface state density, and obtaining a passivation epitaxial wafer;

[0038] Step 4), using chemical mechanical polishing to flatten the surface of the epitaxial wafer passivated in step 3);

[0039] Step 5), performing patterned etching of the source ohmic electrode and the drain ohmic electrode;

[0040] Step 6), vapor dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com