Heat treatment quenching equipment

A quenching equipment and water tank technology, applied in heat treatment equipment, quenching devices, manufacturing tools, etc., can solve the problems of unfavorable product quality, large space occupied, poor cooling effect, etc., so as to achieve inconvenient installation and maintenance, and small space occupied by equipment. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

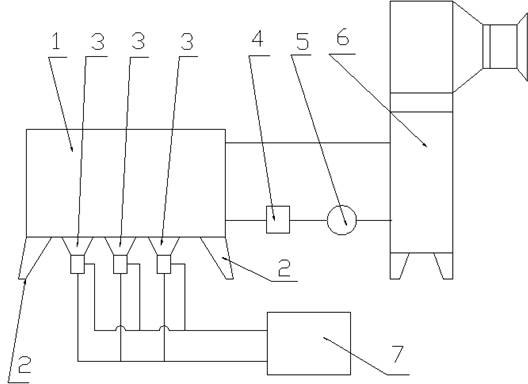

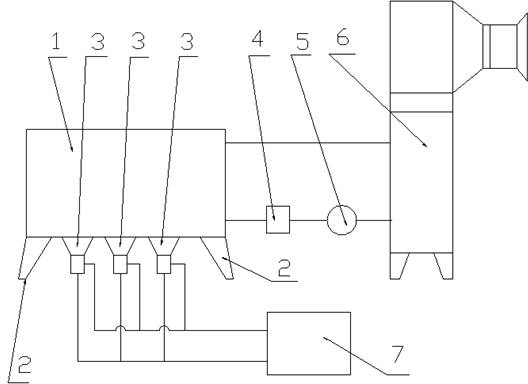

[0009] Install and fix the water tank 1 on the top of the base 2, install and fix the ultrasonic transducer 3 at the bottom of the water tank 1, connect the bottom of the water tank 1 to the inlet end of the filter 4, the water pump 5 and the air cooler 6 through pipelines in sequence, Connect the outlet end of the air cooler 6 with the upper mouth of the water tank 1 , and connect the output end of the ultrasonic generating circuit module 7 with the end of the ultrasonic transducer 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com