Ultraviolet cut-off type EVA photovoltaic adhesive film, preparation method thereof and photovoltaic module

A cut-off, photovoltaic technology, applied in the direction of photovoltaic power generation, adhesives, electrical components, etc., can solve the problems affecting the service life of the backplane and photovoltaic modules, the power generation power of photovoltaic modules is reduced, and the backplane is easy to age and crack, so as to maintain visible light transmission. The effect of high pass rate, low cost, and excellent visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the above-mentioned ultraviolet cut-off type EVA photovoltaic film comprises the following preparation steps:

[0057] In step S1, the EVA resin, antioxidant, crosslinking agent, silane coupling agent, ultraviolet absorber, nano metal oxide and anti-PID functional material of the formula amount are uniformly mixed to obtain a mixture;

[0058] In step S2, the above-mentioned mixture is added to the extrusion equipment for melt extrusion, and after cooling through the casting equipment, the shaping process is carried out, and then thickness measurement, edge trimming, winding, packaging and storage are carried out to obtain the present invention. UV cut-off EVA photovoltaic film.

[0059] Wherein, in step S2, the temperature of melt extrusion is preferably 80-90° C. to ensure the adhesion effect of the EVA photovoltaic film after melt extrusion, and to avoid the aging of the mixture during melt extrusion.

[0060] A photovoltaic module of the p...

Embodiment 1

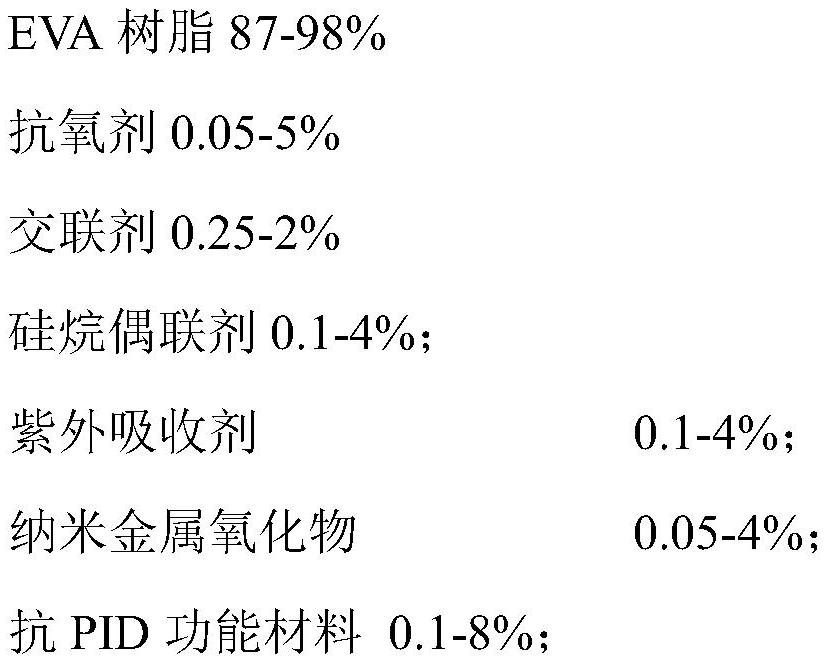

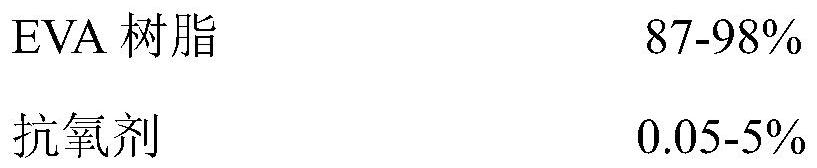

[0062] A UV cut-off type EVA photovoltaic film of the present embodiment includes:

[0063] EVA resin: namely ethylene-vinyl acetate copolymer, wherein, the molar content of vinyl acetate in the ethylene-vinyl acetate copolymer is 28%;

[0064] Antioxidant: The main antioxidant base is β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate octadecyl ester, and the auxiliary antioxidant is tris(4-nonylphenol) sulfite The complex of phosphate ester and tris(2,4-di-tert-butylphenyl) phosphite;

[0065] Cross-linking agent: The cross-linking curing agent is the compound of 2-ethylhexyl peroxide tert-butyl carbonate and 3,3-di(tert-butyl peroxy) ethyl butyrate, and the auxiliary cross-linking agent is triallyl Compounds of isocyanurate, triallyl cyanurate and trimethylolpropane trimethacrylate;

[0066] Silane coupling agent: vinyl tris (β-methoxyethoxy) silane;

[0067] Adamantane: i.e. tricyclic [3.3.1.1 3 ˙]Decane;

[0068] Fullerene: a hollow molecule composed of carbon, contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com