Adhesive film, composition for forming adhesive film, photovoltaic module and laminated glass

A composition and adhesive film technology, applied in the direction of film/sheet adhesive, non-polymer organic compound adhesive, adhesive, etc., can solve the problems of low cost, anti-PID performance, and unsatisfactory encapsulation adhesive film , achieve good flexibility and light transmittance, improve photoelectric conversion efficiency and packaging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

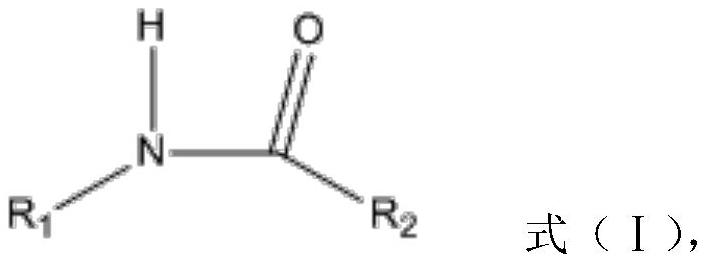

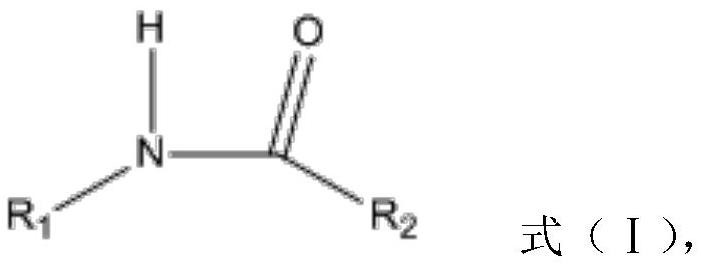

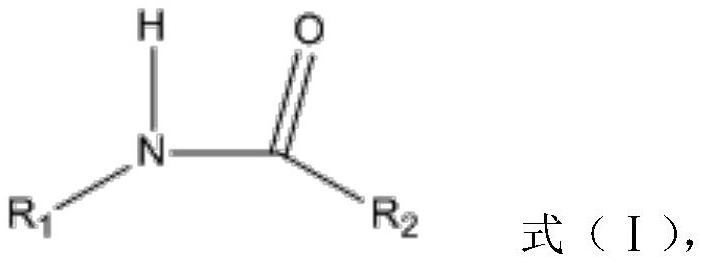

Method used

Image

Examples

Embodiment 1

[0064]Take 100 parts of ethylene-vinyl acetate (VA content 26%, American DuPont), based on 100 parts by weight of the above-mentioned matrix resin, add 0.1 part of magnesium oxide, 1 part of N,N'-dimethylacrylamide, 0.5 1 part of crosslinking agent tert-butylperoxyisopropyl carbonate, 0.5 part of co-crosslinking agent trimethylolpropane trimethacrylate, 1 part of tackifier vinyl triperoxy tert-butylsilane, 0.8 part of light stabilizer Bis-2,2,6,6-tetramethylpiperidinol sebacate. The mixture is uniformly mixed, and the above mixture is premixed, melt-extruded, cast into a film, cooled, cut and rolled, and the like to obtain the anti-PID packaging material.

Embodiment 2

[0066] The difference from Example 1 is that the metal oxide is calcium oxide.

Embodiment 3

[0068] The difference from Example 1 is that the metal oxide is zinc oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com