Compression-resistant waterproof environment-friendly coating

An environmentally friendly coating, pigment and filler technology, applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as adverse effects on people and the environment, poor elongation of heat-insulating coatings, general anti-corrosion effects, etc., to achieve excellent Stretch ability, improve stretch and waterproof performance, improve the effect of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

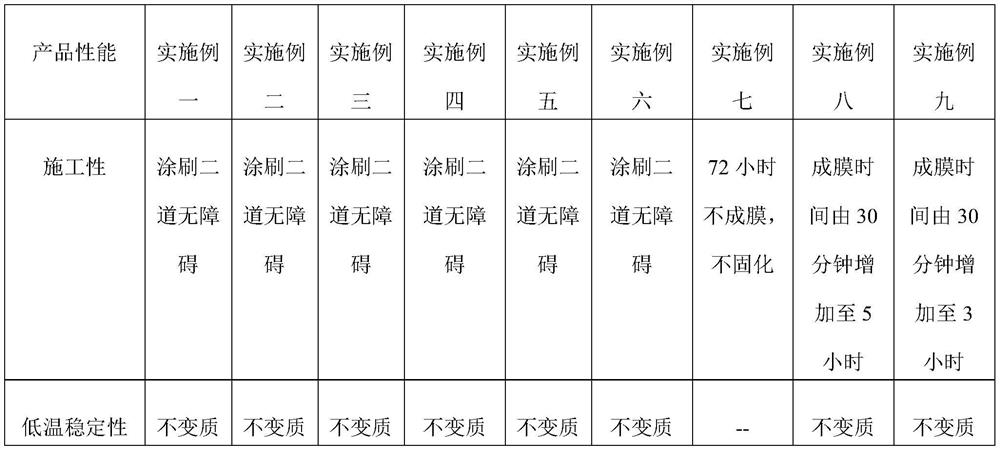

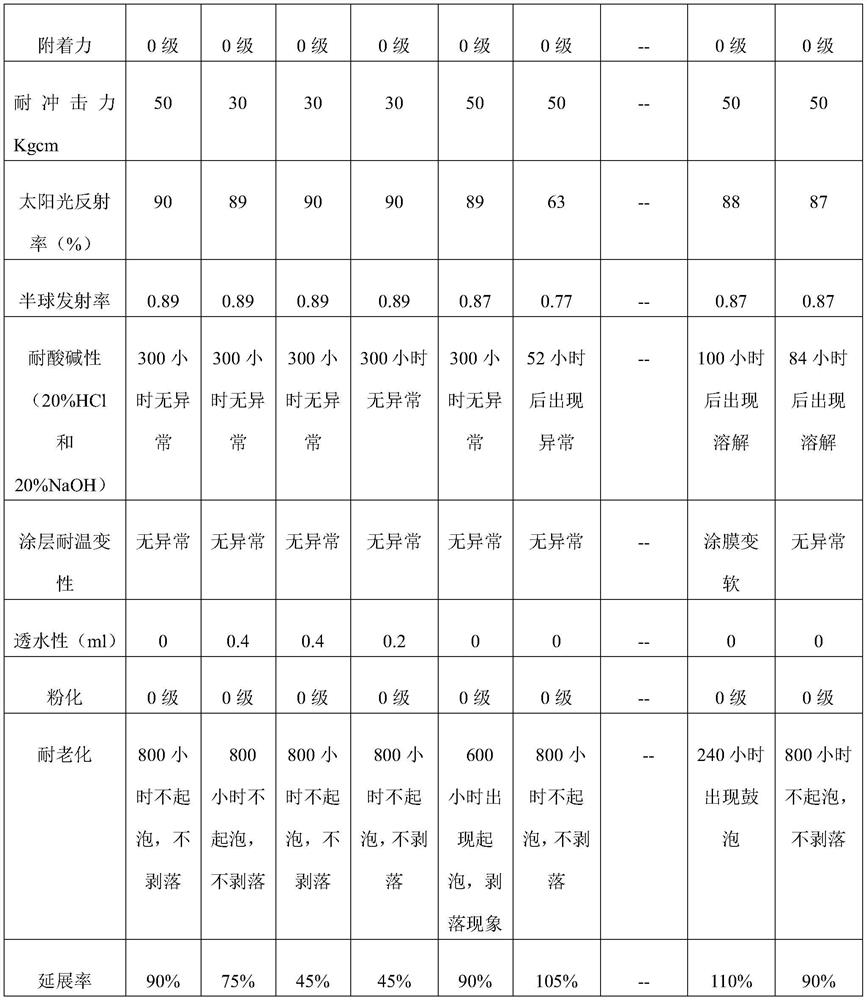

Examples

Embodiment 1

[0023] 100g of titanium dioxide, 70g of magnesium sulfate, 40g of calcium carbonate, 10g of bentonite and 10g of dispersant were added to 200g of deionized water, and the stirring speed was 1000 rpm for 1 hour, and then 120g of nano-ceramic microbeads and 100g of hollow glass 1g toughening agent (liquid nitrile rubber), 300g acrylic resin, 40g 2,4-toluene diisocyanate, 20g ethylenediamine, and 20g graphene nanosheets were added to the mixture, and the stirring speed was reduced to 500 rpm and continued stirring for 50 minute. 10g of defoaming agent, 12g of film-forming agent, 4g of leveling agent and 4g of preservative were continuously stirred for 30 minutes to obtain a pressure-resistant waterproof and environmentally friendly coating, and 0.4g of dibutyltin dilaurate was added during construction.

Embodiment 2

[0025] 100g of titanium dioxide, 70g of magnesium sulfate, 40g of calcium carbonate, 10g of bentonite and 10g of dispersant were added to 200g of deionized water, and the stirring speed was 1000 rpm for 1 hour, and then 120g of nano-ceramic microbeads and 100g of hollow glass 300g of acrylic resin, 40g of 2,4-toluene diisocyanate, 20g of ethylenediamine, and 20g of graphene were added to the mixed solution, and the stirring speed was reduced to 500 rpm and continued stirring for 50 minutes. 10g of defoamer, 12g of film-forming agent, 4g of A leveling agent and 4 g of a preservative are added, and stirring is continued for 30 minutes to obtain a pressure-resistant, waterproof and environmentally friendly paint. 0.4 g of dibutyltin dilaurate was added during construction.

Embodiment 3

[0027] Add 100g titanium dioxide, 70g magnesium sulfate, 40g calcium carbonate, 10g bentonite and 10g dispersant to 200g deionized water, stir at 1000 rpm, stir for 1 hour, then add 120g ceramic microbeads, 100g glass microbeads, 300g acrylic acid Resin, 4g 2,4-toluene diisocyanate, 20g ethylenediamine, 20g graphene were added to the mixed solution, the stirring speed was reduced to 500 rpm and stirring was continued for 50 minutes, 10g defoamer, 12g film-forming agent, 4g leveling agent and 4 g of preservatives, and continued stirring for 30 minutes to obtain a pressure-resistant, waterproof and environmentally friendly paint. No dibutyltin dilaurate was added during construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com