Modified high-impact-resistance polystyrene and preparation method thereof

A polystyrene, high-impact technology, applied in the field of modified high-impact polystyrene and its preparation, can solve the problems of poor impact resistance and poor aging resistance of polystyrene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

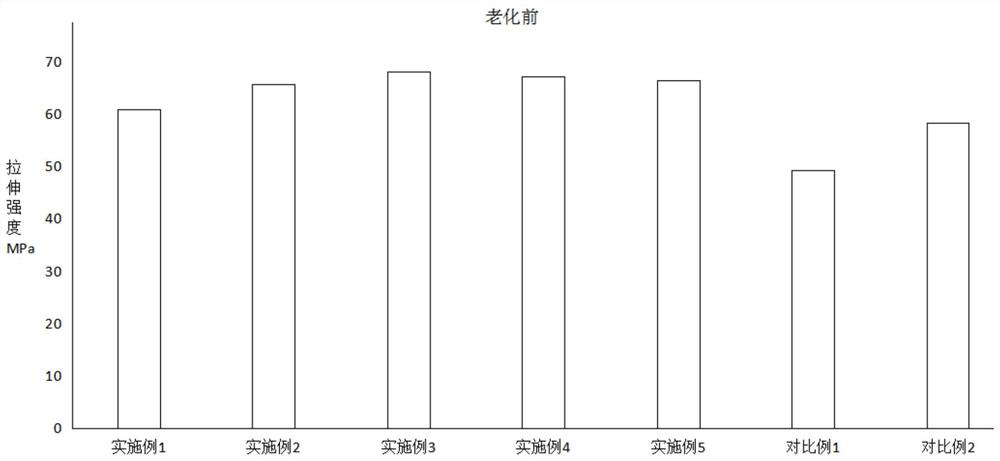

Examples

Embodiment 1

[0045] (1) adding polystyrene, maleic anhydride and dicumyl peroxide with a mass ratio of 1000:7:0.5 to a twin-screw extruder for blending, the blending temperature is 205°C, and the blending time is 15min, after mixing uniformly, extrusion and granulation to obtain maleic anhydride modified polystyrene;

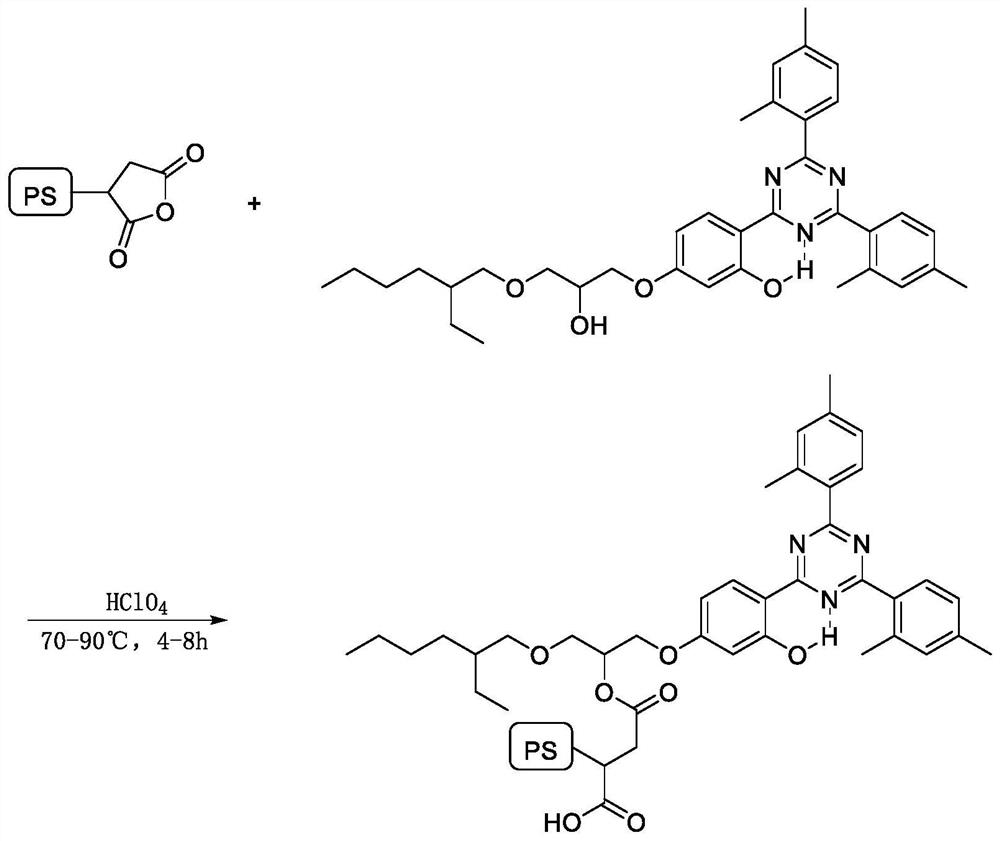

[0046] (2) acetone, maleic anhydride modified polystyrene, 2-[2-hydroxy-4-[3-(2-ethylhexyloxy)-2- Hydroxypropoxy]phenyl]-4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine and perchloric acid were stirred and mixed, and reacted at 70°C for 4h. After the reaction was completed , filtered first, then washed with deionized water, and after washing, vacuum-dried at 50 °C for 5 h to obtain modified polystyrene;

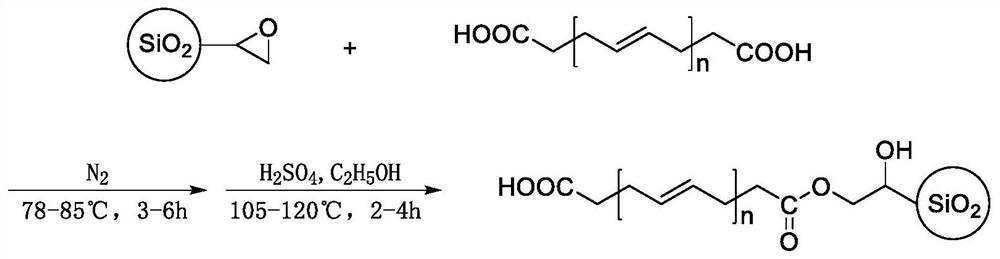

[0047] (3) ultrasonically disperse toluene and nano-silicon dioxide at 20°C for 30 minutes, and after mixing uniformly, add γ-(2,3-glycidoxy)propyltrimethoxysilane, wherein the added toluene, nano-dioxide The mass ratio of silica and γ-(2,3-glycidoxy)propyltrimethoxysilane is ...

Embodiment 2

[0051] (1) adding polystyrene, maleic anhydride and dicumyl peroxide with a mass ratio of 1000:12:0.8 to a twin-screw extruder for blending, the blending temperature is 215°C, and the blending time is 18min, after mixing uniformly, extrusion and granulation to obtain maleic anhydride modified polystyrene;

[0052] (2) The mass ratio of acetone, maleic anhydride modified polystyrene, 2-[2-hydroxy-4-[3-(2-ethylhexyloxy)-2- Hydroxypropoxy]phenyl]-4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine and perchloric acid were stirred and mixed, and reacted at 75°C for 5h. After the reaction was completed , first filtered, then washed with deionized water, and after washing, vacuum-dried at 55 °C for 6 h to obtain modified polystyrene;

[0053] (3) ultrasonically disperse toluene and nano-silicon dioxide at 25°C for 35 minutes, and after mixing uniformly, add γ-(2,3-glycidoxy)propyltrimethoxysilane, wherein the added toluene, nano-dioxide The mass ratio of silicon oxide and γ-(2,3-glycidoxy)...

Embodiment 3

[0057] (1) adding polystyrene, maleic anhydride and dicumyl peroxide with a mass ratio of 1000:15:1 to a twin-screw extruder for blending, the blending temperature is 220°C, and the blending time is 20min, after mixing uniformly, extrusion and granulation to obtain maleic anhydride modified polystyrene;

[0058] (2) The mass ratio of acetone, maleic anhydride modified polystyrene, 2-[2-hydroxy-4-[3-(2-ethylhexyloxy)-2- Hydroxypropoxy]phenyl]-4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine and perchloric acid were stirred and mixed, and reacted at 80 °C for 6 h. After the reaction was completed , first filtered, then washed with deionized water, and after washing, vacuum-dried at 55 °C for 7 h to obtain modified polystyrene;

[0059] (3) ultrasonically disperse toluene and nano-silicon dioxide at 30°C for 40 minutes, and after mixing uniformly, add γ-(2,3-glycidoxy)propyltrimethoxysilane, wherein the added toluene, nano-dioxide The mass ratio of silicon oxide and γ-(2,3-glycidoxy)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com