Method for refining pyromellitic dianhydride

A technology of pyromellitic dianhydride and crude anhydride, which can be used in sustainable manufacturing/processing, organic chemistry, climate sustainability, etc., and can solve problems such as low quality, uneven particle size, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

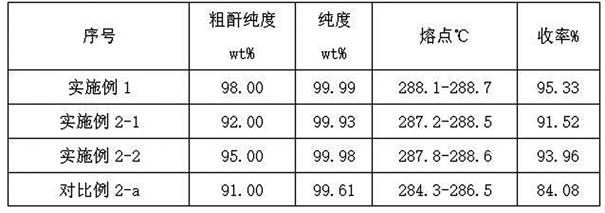

Examples

Embodiment 1

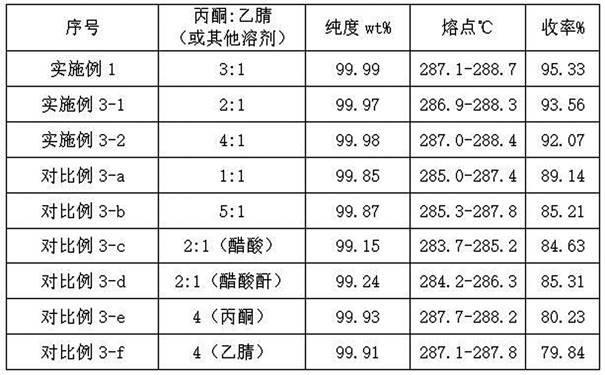

[0028] First, add a mixed solvent of 3 parts of acetone and 1 part of acetonitrile (in a ratio of 3:1 by weight) to the reaction vessel, and start stirring; then add 0.5 part of 98% crude anhydride (crude anhydride and mixed solvent in a ratio of 1:8 by weight) ) into the reaction vessel, continue to heat up and reflux until the crude anhydride is basically dissolved, and the reflux temperature is 65 ° C; then hot filtration to remove insoluble impurities;

[0029] At 65°C, the air containing 3.5vt% ozone was fed into the filtrate for oxidation, and kept for 30min, and the amount of air fed was 60-80 times / hour of the solvent volume; then 1 / 2 of the weight of the solvent was distilled out; then The remaining mother liquor was cooled to 20°C, the cooling rate was 1°C / min, and the stirring rate was controlled at 135r / min until the crystals were precipitated; then the crystalline material was filtered through a vacuum dryer, the vacuum degree was maintained at 0.08-0.09MPa, and th...

Embodiment 2-1

[0035] 92% crude anhydride was used instead, and others were the same as in Example 1.

Embodiment 2-2

[0037] 95% crude anhydride was used instead, and others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com