M-bit binary MAX phase material as well as preparation method and application thereof

A technology of reaction and molten salt method, applied in the field of materials, can solve the problems of MAX phase materials that have not been reported in the literature, and achieve the effect of enriching applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Another aspect of the embodiments of the present invention provides a method for preparing an M-site binary MAX phase material, including, but not limited to, a molten salt method, a hot pressing method, a spark plasma sintering method, and the like.

[0037] In some embodiments, the preparation method specifically includes:

[0038] M and / or M-containing materials, M' and / or M'-containing materials, A and / or A-containing materials, X and / or X-containing materials, and inorganic salts are calculated as (0.01~3.99):(0.01~3.99): The molar ratio of 1:(1~3):(0~10) is mixed, and the obtained mixture is reacted in an inert atmosphere at a high temperature of 800 ℃~1700 ℃ under atmospheric pressure for 180~420min, and then post-processing to obtain an M-position binary The MAX phase material; the molecular formula of the M-bit binary MAX phase material is expressed as (M x ,M′ y ) n+1 AX n , 0<x<1, 0<y<1, x+y=1, where M and M' respectively include Ta, Sc, Hf, V, Nb, Mo, Zr...

Embodiment 1

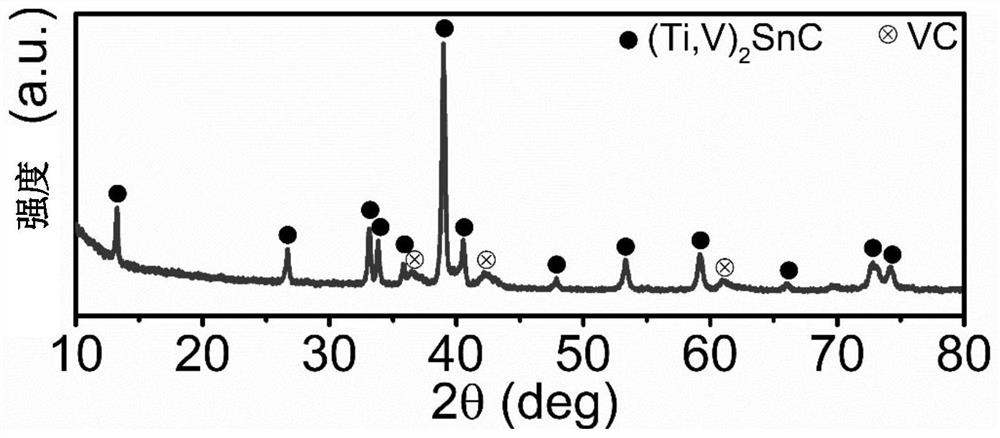

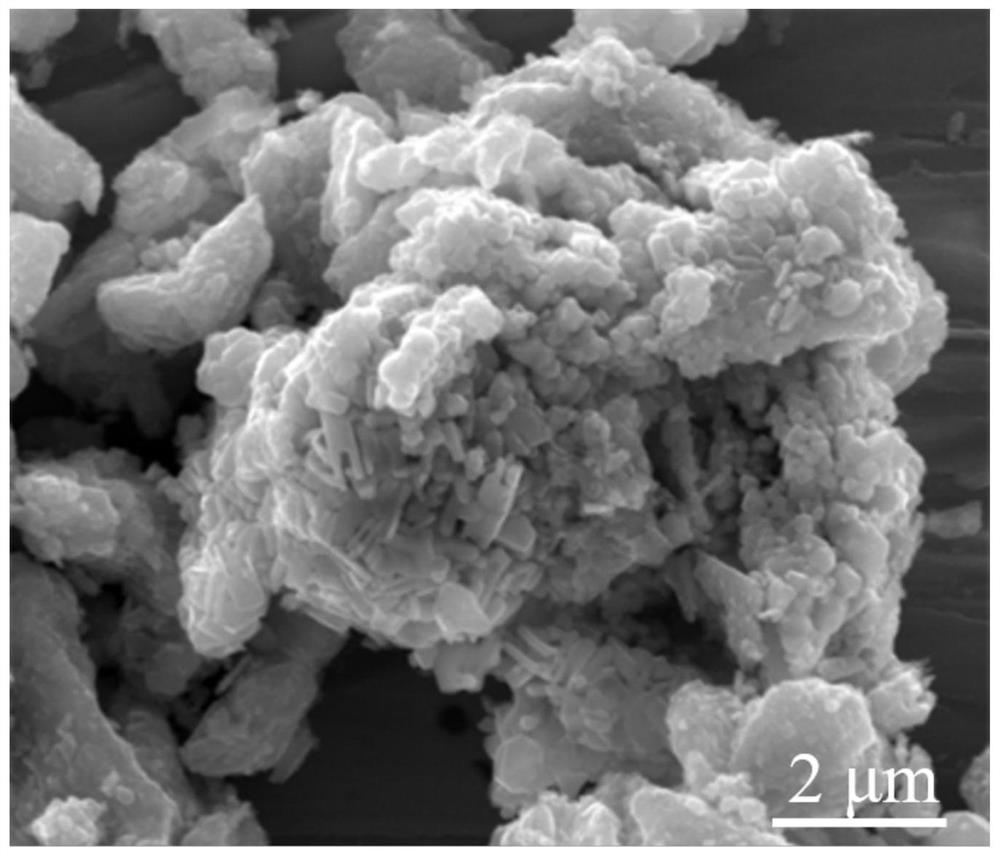

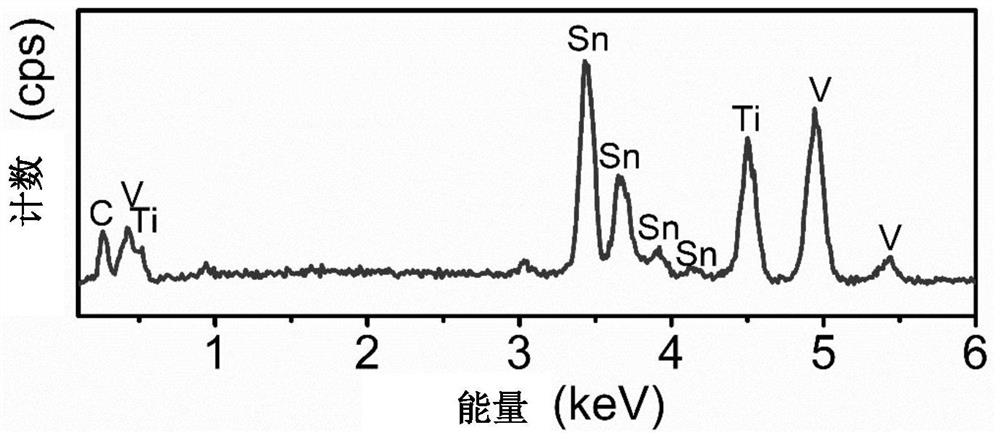

[0051] Embodiment 1: In this embodiment, the M-bit binary MAX phase material is (Ti x V y ) 2 SnC bulk material.

[0052] The (Ti x V y ) 2 The preparation method of SnC block is as follows:

[0053] (1) Weigh TiC powder, V powder, Sn powder and carbon powder according to the ratio of 1:1:1:1, grind and mix the above materials to obtain a mixture.

[0054] (2) The mixture is placed in a graphite mold for spark plasma sintering. The reaction conditions are as follows: the reaction temperature is 1600° C., the holding time is 200 min, the pressure is 10 kN, and the inert atmosphere is protected. After the temperature dropped to room temperature, the reaction product in the graphite mold was taken out.

[0055] (3) polishing the reaction product to remove the surface impurity phase. After immersion in ethanol and ultrasonic cleaning, it was put into an oven at 50 ° C, and taken out after 12 hours to obtain a bulk product (Ti x V y ) 2 SnC.

[0056] The bulk product (...

Embodiment 2

[0057] Embodiment 2: In this embodiment, the M-bit binary MAX phase material is (V x Nb y ) 2 SnC powder material.

[0058] The (V x Nb y ) 2 The preparation method of SnC powder is as follows:

[0059] (1) Weigh VC powder, Nb powder, Sn powder and inorganic salt (NaCl+KCl) in a ratio of 1:1:1:1:10, grind and mix the above materials to obtain a mixture.

[0060] (2) The mixture is placed in a corundum crucible and placed in a high-temperature tube furnace for reaction. The reaction conditions were as follows: the reaction temperature was 1200° C., the holding time was 240 min, and the inert atmosphere was protected. After the temperature of the tube furnace was lowered to room temperature, the reaction product in the crucible was taken out.

[0061] (3) Wash the reaction product with deionized water and alcohol: put the reaction product into a beaker, add deionized water, stir and ultrasonically clean for 30 minutes, and then let stand for 1 hour, and then discard the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com