Sodium-containing oxide positive electrode material, preparation method and application thereof, positive plate and application thereof

A technology for cathode materials and oxides, applied in the field of sodium-containing oxide cathode materials and their preparation, and cathode sheets, can solve the problems of lower discharge specific capacity and rate performance, lower material safety performance, and high soluble alkali content, and achieve improved charging. Discharge capacity, high safety, effect of reducing soluble alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] A second aspect of the present invention provides a method for preparing a sodium-containing oxide cathode material, characterized in that the method comprises the following steps:

[0090] The sodium-containing ferromanganese cathode material precursor is first sintered, and then crushed and sieved after cooling to obtain the sodium-containing oxide cathode material;

[0091] Wherein, in the process of the first sintering, an oxygen-containing atmosphere is introduced;

[0092] The introduction amount of the oxygen-containing atmosphere is 1-15m 3 / h, the humidity of the oxygen-containing atmosphere is less than or equal to 10RH%;

[0093] The temperature T1 of the first sintering satisfies the following conditions: 500×(1+y)≤T1≤400×(3-y)°C, y is the content of Mn in the sodium manganese iron oxide cathode material;

[0094] The constant temperature time of the first sintering is 6-20h;

[0095] The heating rate of the first sintering is less than or equal to 10°C / m...

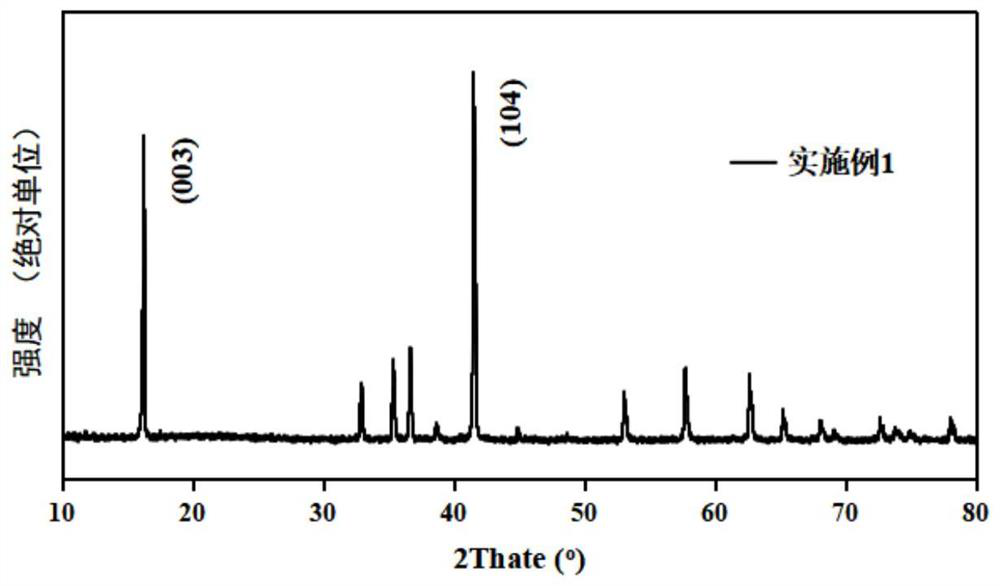

Embodiment 1

[0197] (1) Accurately weigh manganese dioxide, ferric oxide, nickelous oxide, copper oxide and sodium carbonate according to the molar ratio of manganese, iron, nickel, copper and sodium elements as 4:2:2:2:8, add An appropriate amount of ethanol is mixed with the medium, and the ball-milling mixture is uniformly obtained to obtain the precursor Q1 for the cathode material of the sodium-manganese-iron metal oxide.

[0198] (2) The uniformly mixed precursor Q1 is placed in a muffle furnace and heated from room temperature to 850°C (y=0.4), maintained for 15h, and the heating rate is 5°C / min, and the first sintering is performed. During the first sintering process, dry air with humidity less than 5RH% is continuously introduced, and the ventilation volume is 10m 3 / h. After natural cooling, crushing and sieving, the sodium-containing metal oxide cathode material S1 is obtained.

[0199] The preparation methods of Examples 2-7 are similar to those of Example 1, as shown in Tabl...

Embodiment 8

[0207] (1) dissolving manganese sulfate, iron sulfate, nickel sulfate, and copper sulfate according to the molar ratio of manganese, iron, nickel, and copper elements is 4:2:2:2 to obtain a mixed salt solution with a concentration of 2mol / L, and the hydrogen Sodium oxide is dissolved into a precipitant solution with a concentration of 2 mol / L, and ammonia water is dissolved into a complexing agent solution with a concentration of 3 mol / L. The precipitating agent, the complexing agent solution and the mixed salt solution were added to the reaction kettle in parallel, and the reaction was carried out for 30 hours at a temperature of 45 °C, a pH value of 10.5, and a stirring speed of 700 rpm, and then the slurry was filtered and washed. The filter cake is sieved after drying at 120 °C to obtain the process product P8, the chemical formula is Mn 0.4 Fe 0.2 Ni 0.2 Cu 0.2 (OH) 2 .

[0208] (2) Mixing sodium carbonate and precursor Q8 uniformly to obtain precursor Q8.

[0209] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com