Phase change energy storage coating for automobile cab and preparation process of phase change energy storage coating

A phase change energy storage, cab technology, applied in reflection/signal coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of inability to achieve effective temperature control, low phase change enthalpy, poor stain resistance, etc. The problem is to reduce the overheating problem of the car cab, improve the phase change enthalpy value, and enhance the anti-fouling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation technology of the above-mentioned phase change energy storage paint for automobile cab, comprises the following steps:

[0052] 1) Stir the water-based polyol dispersion, film-forming aid, defoamer, leveling agent, and thickener evenly, then add a curing agent, and continue stirring to obtain an outer coating slurry;

[0053] 2) Stir the water-based polyol dispersion, the modified high-reflection material, the film-forming aid, the defoaming agent, the leveling agent, and the thickening agent evenly, then add the curing agent, and continue to stir to obtain the intermediate layer slurry;

[0054] 3) Stir the water-based phase-change polyurethane, film-forming aid, defoamer, leveling agent, and thickener evenly, then add a curing agent, and continue stirring to obtain an inner coating slurry;

[0055] 4) coating the inner coating slurry obtained in step 3) on the substrate, curing, then coating the intermediate layer slurry obtained in step 2), curing, an...

Embodiment 1

[0068] The present embodiment provides the preparation process of phase change energy storage paint for automobile cab, including:

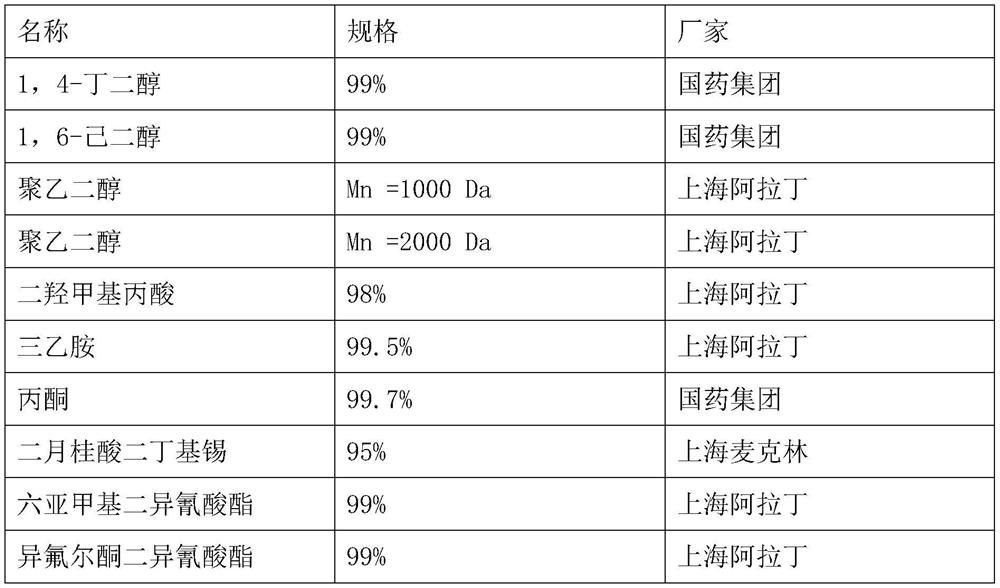

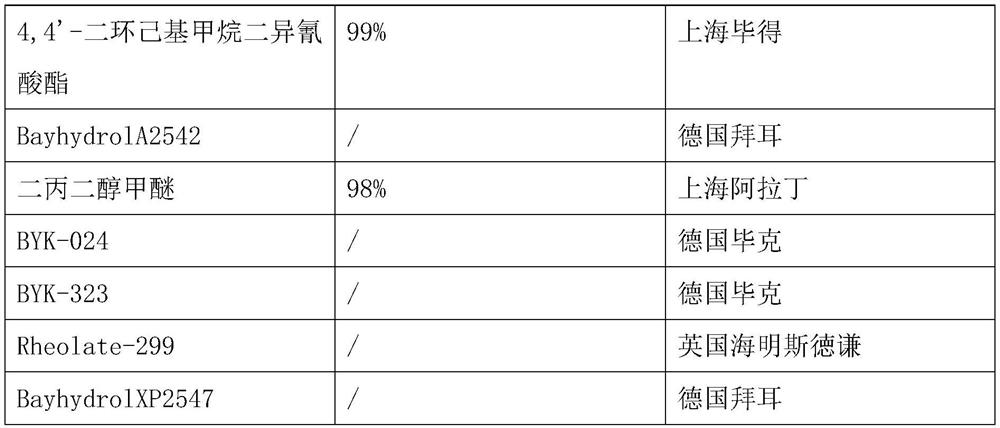

[0069] Dewater 1000Da polyethylene glycol and dimethylolpropionic acid in a vacuum oven at 110°C for 4 hours, and hexamethylene diisocyanate to remove water with molecular sieve for 4 hours. Polyethylene glycol and an appropriate amount of acetone solvent were added to the reaction kettle, stirred at a high speed of 400r / min, reacted at 50°C for 4h, added 13.5g of dimethylolpropionic acid, continued to react for 2h under the action of the catalyst dibutyltin dilaurate, and added 18g of dimethylolpropionic acid. 1,4-Butanediol continued to react for 1 h, cooled to room temperature, neutralized by adding 10.1 g of triethylamine, and under high-speed stirring at 800 r / min, deionized water was added dropwise to the device for emulsification, and then distilled under reduced pressure until there was no more in the emulsion. Residual acetone yields an ...

Embodiment 2

[0076] The present embodiment provides the preparation process of phase change energy storage paint for automobile cab, including:

[0077] Dewater 1000Da polyethylene glycol and dimethylolpropionic acid in a vacuum oven at 110°C for 4 hours, and use molecular sieve to remove water for isophorone diisocyanate for 4 hours. An appropriate amount of acetone solvent was added to the reaction kettle, stirred at a high speed of 500 r / min, reacted at 50 °C for 2 h, added 13.5 g of dimethylolpropionic acid, continued to react for 2 h under the action of the catalyst dibutyltin dilaurate, and added 23.7 g of 1,6- Hexylene glycol continued to react for 1 h, cooled to room temperature, neutralized by adding 10.1 g of triethylamine, under high-speed stirring at 800 r / min, dropwise added deionized water to the device for emulsification, and distilled under reduced pressure until there was no residual acetone in the emulsion to obtain Waterborne phase change polyurethane.

[0078] Stir 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com