Preparation method of gypsum binder

A binder and gypsum technology, which is applied in the field of preparation of gypsum binders, can solve problems such as unfavorable storage, achieve the effects of improving strength, increasing flexural resistance, and ensuring water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

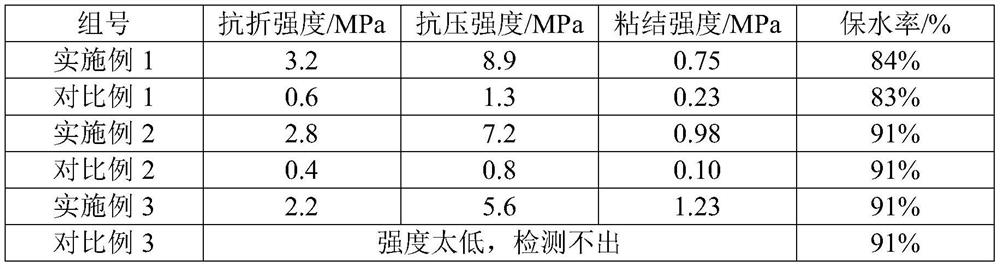

[0033] Pour the semi-dry desulfurization ash into the rotary kiln at 500-650℃ for oxidation and carbonization treatment with air and carbon dioxide (blast furnace flue gas). Desulfurized ash used 0.8m 3 , the ratio of the introduction amount of carbon dioxide in the semi-dry desulfurization ash and carbon dioxide source gas is 0.3 m per ton of semi-dry desulfurization ash 3), grind the treated desulfurization ash until the sieve residue of 0.3mm square-hole sieve is less than 1.0%, and the sieve residue of 0.15mm square-hole sieve is less than 10%, and then weigh the following materials by weight: 60 parts by weight of ash, 40 parts by weight of hemihydrate gypsum, 0.15 wt % of citric acid (setting retarder is also called binder), 0.05 wt % of hydroxypropyl methyl cellulose ether, and can be mixed evenly in 0.5 wt % of dispersing rubber powder That is, a gypsum binder is obtained, wherein the retarder, the water-retaining agent, and the reinforcing agent are added by external...

Embodiment 2

[0037] Pour the semi-dry desulfurization ash into the rotary kiln at 500-650℃ for oxidation and carbonization treatment with air and carbon dioxide (blast furnace flue gas). Desulfurization ash use 0.65m 3 , the ratio of the amount of carbon dioxide introduced into the semi-dry desulfurization ash to the carbon dioxide source gas is 0.38m per ton of semi-dry desulfurization ash 3 ), grind the treated desulfurization ash until the sieve residue of 0.3mm square-hole sieve is less than 1.0%, and the sieve residue of 0.15mm square-hole sieve is less than 10%, and then weigh the following materials by weight: 65% of the ground desulfurization ash , 35% of hemihydrate gypsum, 0.1% of citric acid, 0.07% of hydroxypropyl methyl cellulose ether, and 0.8% of disperse rubber powder can be mixed evenly to obtain gypsum binder, wherein the retarder, water retention agent and enhancer are by way of external doping. After mixing the above materials evenly, add 44% water and stir evenly, an...

Embodiment 3

[0041] The semi-dry desulfurization ash is introduced into the rotary kiln at 500-650℃ for oxidation and carbonization treatment, and the treated desulfurization ash is ground to a 0.3mm square hole sieve with less than 1.0% sieve residue and a 0.15mm square hole sieve. The remaining amount is less than 10%, and then weigh the following materials by weight: 70% of ground desulfurization ash, 30% of hemihydrate gypsum, 0.1% of citric acid, 0.07% of hydroxypropyl methyl cellulose ether, disperse rubber powder The gypsum binder is obtained by mixing 1.0% evenly, wherein the setting retarder, the water-retaining agent and the reinforcing agent are added in the form of external admixture. After mixing the above materials evenly, add 42% water and stir evenly, and then pour the uniformly stirred slurry into shape, and test the relevant performance indicators after hardening and demoulding, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com