Waterproof isolation plate and preparation method thereof

A technology of isolation board and forming agent, which is applied in the field of building materials, can solve environmental pollution and other problems, and achieve the effect of improving strength, toughness and strength, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

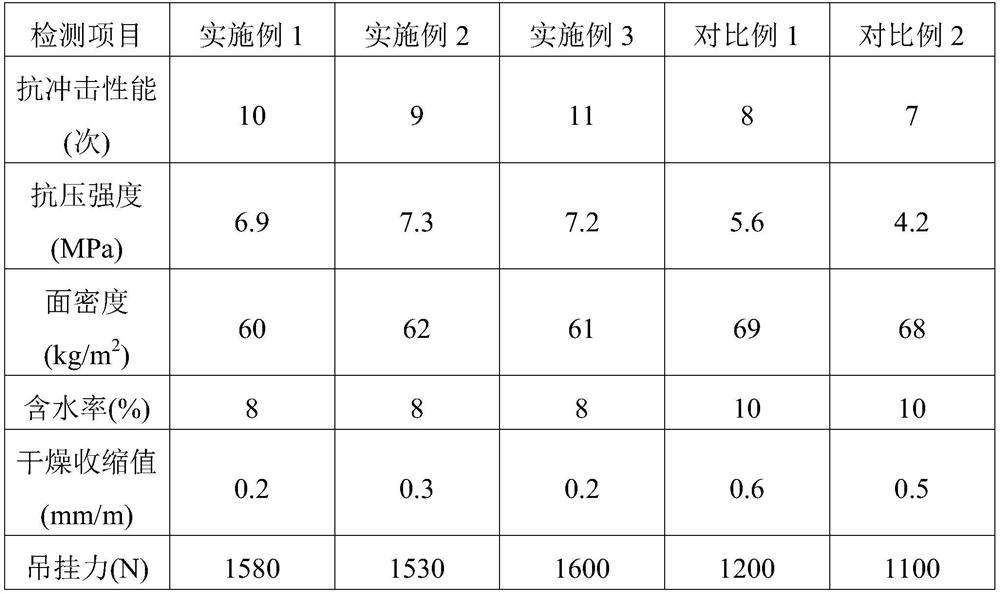

Examples

Embodiment 1

[0045] A kind of waterproof isolation board, comprises following raw materials prepared by weight:

[0046] 65 parts of alkali residue,

[0047] 5 parts of aggregate forming agent,

[0048] 8 parts of white ash,

[0049] 3 parts of cellulose;

[0050] The aggregate forming agent comprises the following components by weight:

[0051] 15 parts of alkali residue,

[0052] 35 parts of steel slag,

[0053] 3 parts of waste plaster mold,

[0054] 30 parts of cement clinker.

[0055] The preparation method of above-mentioned waterproof isolation plate, comprises the following steps:

[0056] (1) Take alkali slag, dry at 680°C until the water content is below 8wt%, and grind to obtain alkali slag powder, the particle size of which is below 100 μm;

[0057] (2) Preparation of aggregate forming agent: take alkali slag, steel slag, waste gypsum mold, cement clinker respectively, pulverize, grind, sieve, obtain alkali slag powder, steel slag powder, waste gypsum mold powder and ge...

Embodiment 2

[0061] A kind of waterproof isolation board, comprises following raw materials prepared by weight:

[0062] 75 parts of alkali residue,

[0063] 10 parts of aggregate forming agent,

[0064] 12 parts of white ash,

[0065] 6 parts of cellulose;

[0066] The aggregate forming agent comprises the following components by weight:

[0067] 25 parts of alkali residue,

[0068] 45 parts of steel slag,

[0069] 6 parts of waste plaster mold,

[0070] 35 parts of gelling material,

[0071] 1.5 parts of additives;

[0072] The cementitious material is clinker cement,

[0073] The additives are enhancers.

[0074] The preparation method of above-mentioned waterproof isolation plate, comprises the following steps:

[0075] (1) Take alkali slag, dry at 720°C until the water content is below 8wt%, and grind to obtain alkali slag powder, the particle size of which is below 100 μm;

[0076] (2) Preparation of aggregate forming agent: get alkali slag, steel slag, waste gypsum mold, ...

Embodiment 3

[0080] A kind of waterproof isolation board, comprises following raw materials prepared by weight:

[0081] 70 parts of alkali residue,

[0082] 10 parts of aggregate forming agent,

[0083] 10 parts of white ash,

[0084] 5 parts of cellulose;

[0085] The aggregate forming agent comprises the following components by weight:

[0086] 20 parts of alkali residue,

[0087] 40 parts of steel slag,

[0088] 5 parts of waste plaster mold,

[0089] 34 parts of gelling material,

[0090] Additive 1 part;

[0091] The cementitious material is cement clinker;

[0092] The additive is a grinding aid.

[0093] The preparation method of above-mentioned waterproof isolation plate, comprises the following steps:

[0094] (1) Take alkali slag, dry at 700°C until the water content is below 8wt%, and grind to obtain alkali slag powder, the particle size of which is below 100 μm;

[0095] (2) Preparation of aggregate forming agent: get alkali slag, steel slag, waste gypsum mold, ceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com