Super-hydrophilic antibacterial aluminum foil

A super-hydrophilic, aluminum foil technology, used in antifouling/underwater coatings, biocide-containing paints, polyether coatings, etc., can solve the problem of increasing wind resistance, shortening the service life of air conditioners, inorganic aluminum foil substrates and organic Problems such as poor coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

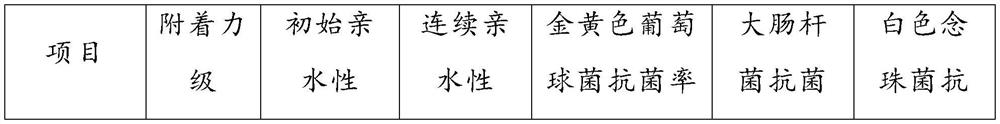

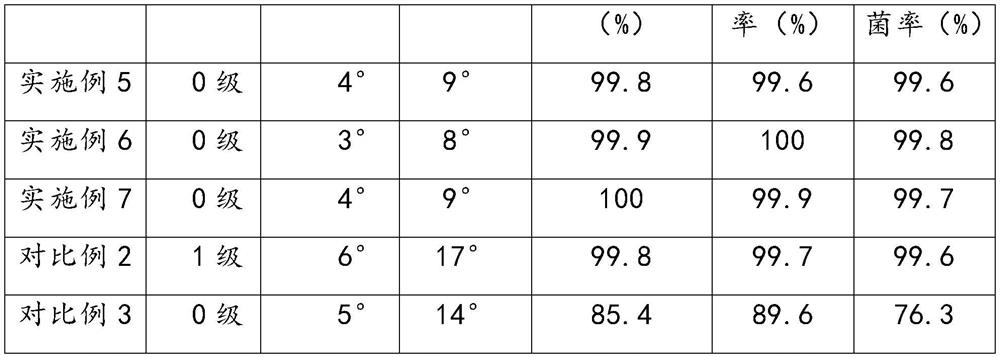

Examples

Embodiment 1

[0031] The present embodiment provides a kind of unsaturated tertiary amino derivative, which is made by the following steps:

[0032] Step B1, add 0.1mol diethanolamine and 40mL deionized water to the four-necked flask, under nitrogen protection, stir and heat up to 55 ° C, add 0.1mol allyl glycidyl ether dropwise, control the rate of addition of 1 drop / second, add dropwise After the end, the reaction was incubated for 2h, and after the reaction was finished, the deionized water was removed by rotary evaporation to obtain an intermediate product;

[0033] Step B2, mixing 0.05mol 4-aminomethylbenzoic acid, 10.2g intermediate product, 120mL DMF and 5mL toluene, adding p-toluenesulfonic acid, stirring and reacting at a temperature of 110 ° C for 4h, after the reaction is completed, removing DMF by vacuum distillation to obtain For the unsaturated tertiary amino derivative, the amount of p-toluenesulfonic acid used is 2% of the mass sum of 4-aminomethylbenzoic acid and the interm...

Embodiment 2

[0035] The present embodiment provides a kind of unsaturated tertiary amino derivative, which is made by the following steps:

[0036] Step B1, add 0.1mol diethanolamine and 50mL deionized water to the four-necked flask, under nitrogen protection, stir and heat up to 55°C, add 0.11mol allyl glycidyl ether dropwise, control the rate of addition to 3 drops / second, add dropwise After the end, the reaction was incubated for 2h, and after the reaction was finished, the deionized water was removed by rotary evaporation to obtain an intermediate product;

[0037] Step B2, mix 0.05mol 4-aminomethylbenzoic acid, 10.5g intermediate product, 150mL DMF and 8mL toluene, add p-toluenesulfonic acid, stir and react at a temperature of 120 ° C for 6h, after the reaction is completed, remove DMF by vacuum distillation to obtain For the unsaturated tertiary amino derivative, the amount of p-toluenesulfonic acid used is 2% of the mass sum of 4-aminomethylbenzoic acid and the intermediate product. ...

Embodiment 3

[0039] The present embodiment provides a kind of modified silica, which is made by the following steps:

[0040] Step A1, ultrasonically disperse 2 g of mesoporous silica, 10 mL of deionized water and 40 mL of anhydrous ethanol, add 4 mL of 3-aminopropyltriethoxysilane, stir and react at 60°C for 6 hours, after the reaction, centrifuge and precipitate After washing three times with deionized water, vacuum drying to obtain aminated mesoporous silica;

[0041] Step A2: Add 40 mg of aminated mesoporous silica, 1.8 mg of polyvinylpyrrolidone, 20 mL of methanol and 10 mL of silver nitrate solution into the round-bottomed flask, stir for 6 h in the dark, add dropwise 40-50 mL of sodium borohydride solution, and stir to react After 30min, centrifuge, the precipitate is washed with absolute ethanol and deionized water, respectively, and freeze-dried to obtain silver-loaded silica, the concentration of silver nitrate solution is 4mmol / L, and the concentration of sodium borohydride solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com