Hydrophilic antibacterial coating for automobile air conditioner evaporator and preparation method thereof

An antibacterial coating, automotive air conditioning technology, applied in coatings, antifouling/underwater coatings, biocide-containing paints, etc. Long-lasting antibacterial properties and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0026] Specific embodiment preparation method:

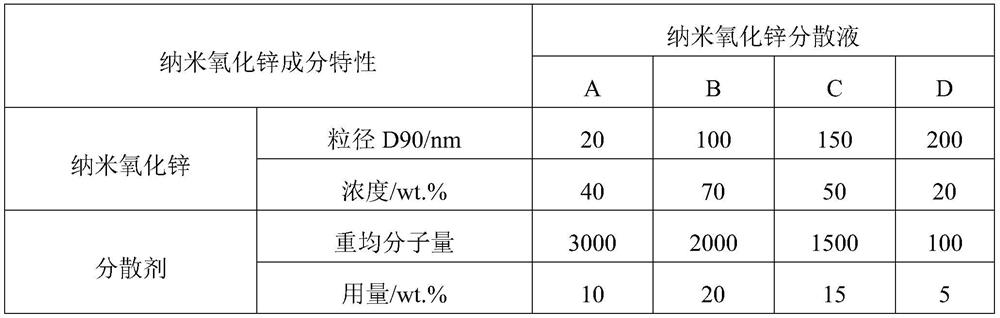

[0027] 1) Preparation of nano-zinc oxide dispersion: place nano-zinc oxide, dispersant and deionized water in a sand mill for grinding to obtain nano-zinc oxide dispersion;

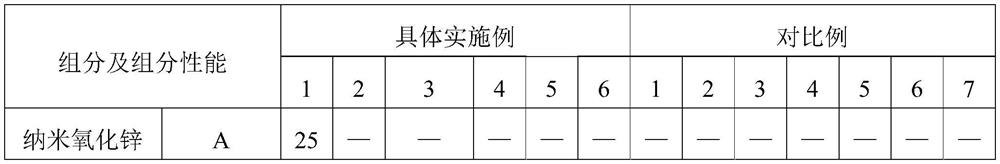

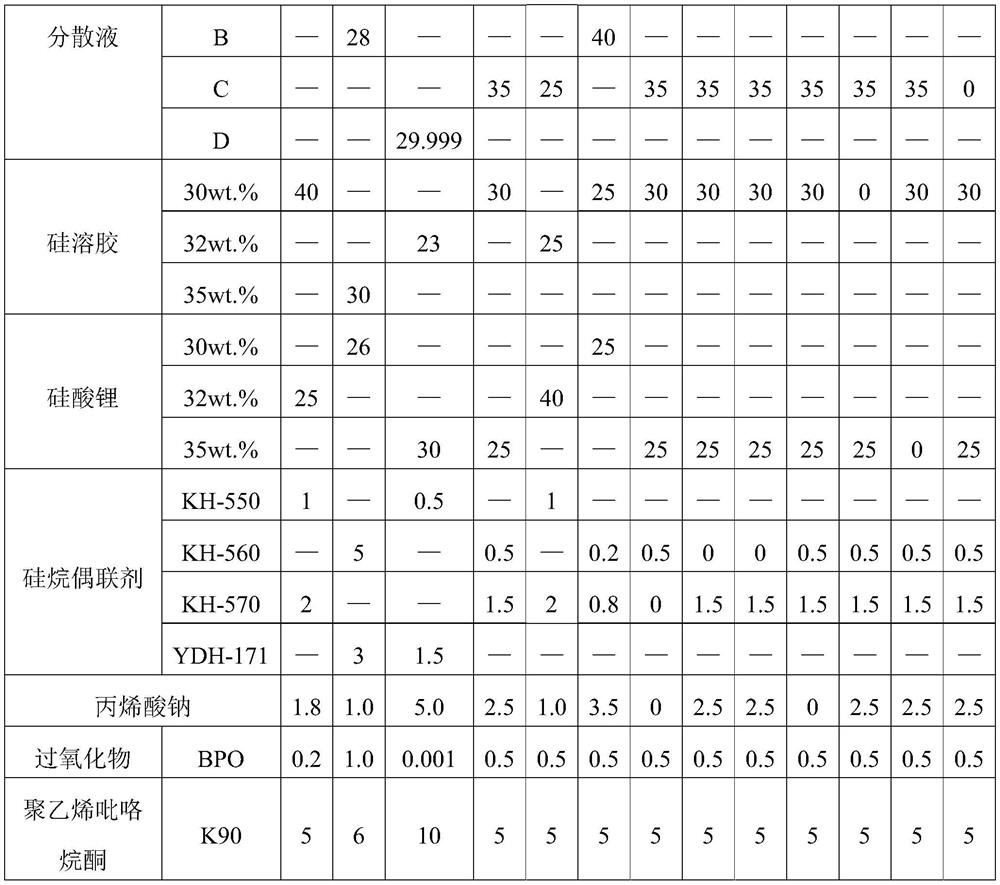

[0028] 2) Preparation of coating solution: Weigh each component except polyvinylpyrrolidone as described in Table 1, then carry out polymerization reaction at 80-100°C for 2-4h, and then cool down to room temperature naturally to obtain a mixed liquid ; Mix the obtained mixed liquid with the weighed polyvinylpyrrolidone at room temperature to obtain a coating liquid;

[0029] 3) Preparation of hydrophilic antibacterial coating: immerse the evaporator in the coating solution obtained in 2) and dry it, place it in an environment of 100-200°C and bake it for 3-5min to form a 1-5μm thick coating on the evaporation surface Hydrophilic antibacterial coating on the device.

[0030] The comparative examples described in the application are all designed with re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com