Flexible bendable metal pattern based on laser technology and preparation method and application thereof

A technology of metal patterns and laser technology, which is applied in metal material coating process, printed circuit manufacturing, circuit substrate materials, etc., can solve the problems of loss of conductivity, damage to polymer matrix, easy fracture of copper layer, etc., and achieve low cost, Simple operation and good production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

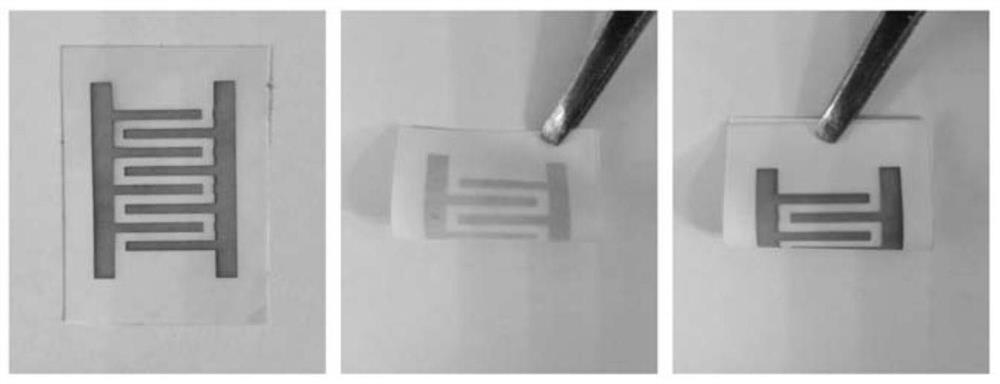

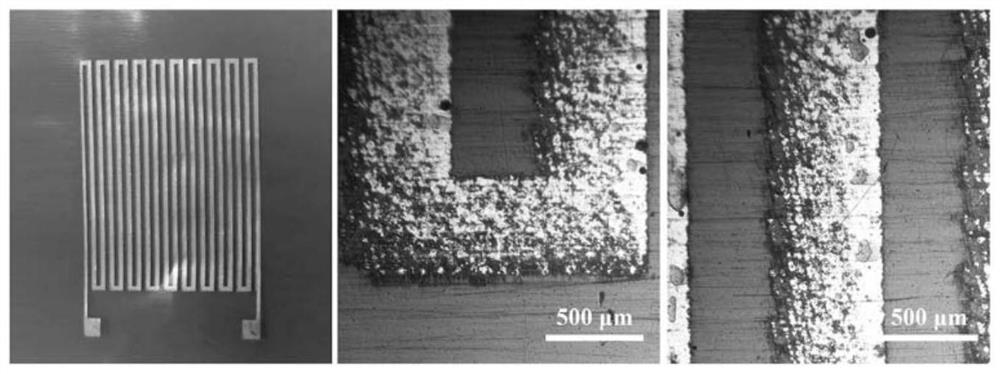

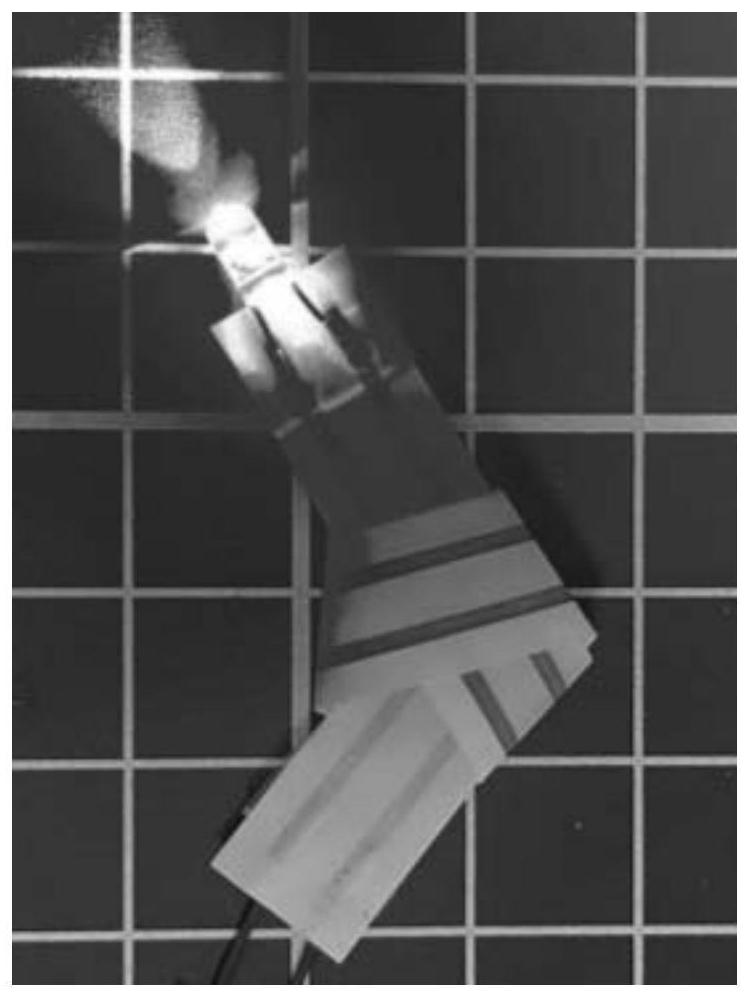

[0045] Example 1. Preparation of Flexible Bendable Metal Patterns

[0046] The laser sensitizer suspension was obtained by stirring and mixing 2wt.% zinc-barium white and 98wt.% deionized water. The suspension was scraped on the porous PA film with a pore size of 0.05 μm using a scraper, and the solvent was removed by drying. The surface of the PA film coated with laser sensitizer was irradiated by pulsed laser (192nm) for laser activation. The laser power was 2W, the scanning speed was 500mm / s, the laser frequency was 20kHz, and the excess laser sensitizer was removed by deionized water. The resulting PA film was immersed in an electroless copper plating solution, and copper-plated at 40° C. for 30 min to obtain a conductive metal pattern.

Embodiment 2

[0047] Example 2. Preparation of Flexible Bendable Metal Patterns

[0048] The laser sensitizer suspension was obtained by stirring and mixing 2wt.% zinc hydroxide with 98wt.% deionized water. The suspension was scraped on a porous PA film with a pore size of 0.05 μm using a scraper, and the solvent was removed by drying. Use pulsed laser (355nm) to irradiate the surface of PA film coated with laser sensitizer for laser activation, laser power 5W, scanning speed 1000mm / s, laser frequency 50kHz, deionized water to remove excess laser sensitizer, and the cleaning The resulting PA film was immersed in an electroless copper plating solution, and copper-plated at 40° C. for 30 min to obtain a conductive metal pattern.

Embodiment 3

[0049] Example 3. Preparation of Flexible Bendable Metal Patterns

[0050] The laser sensitizer suspension was obtained by stirring and mixing 2wt.% copper phosphate and 98wt.% deionized water. The suspension was scraped on a porous PA film with a pore size of 0.05 μm using a scraper, and the solvent was removed by drying. Pulse laser (1064nm) irradiates the surface of the PA film coated with laser sensitizer for laser activation, laser power 8W, scanning speed 2000mm / s, laser frequency 80kHz, deionized water to remove excess laser sensitizer, after cleaning The PA film was immersed in the electroless copper plating solution, and the conductive metal pattern was prepared by copper plating at 40 °C for 30 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com