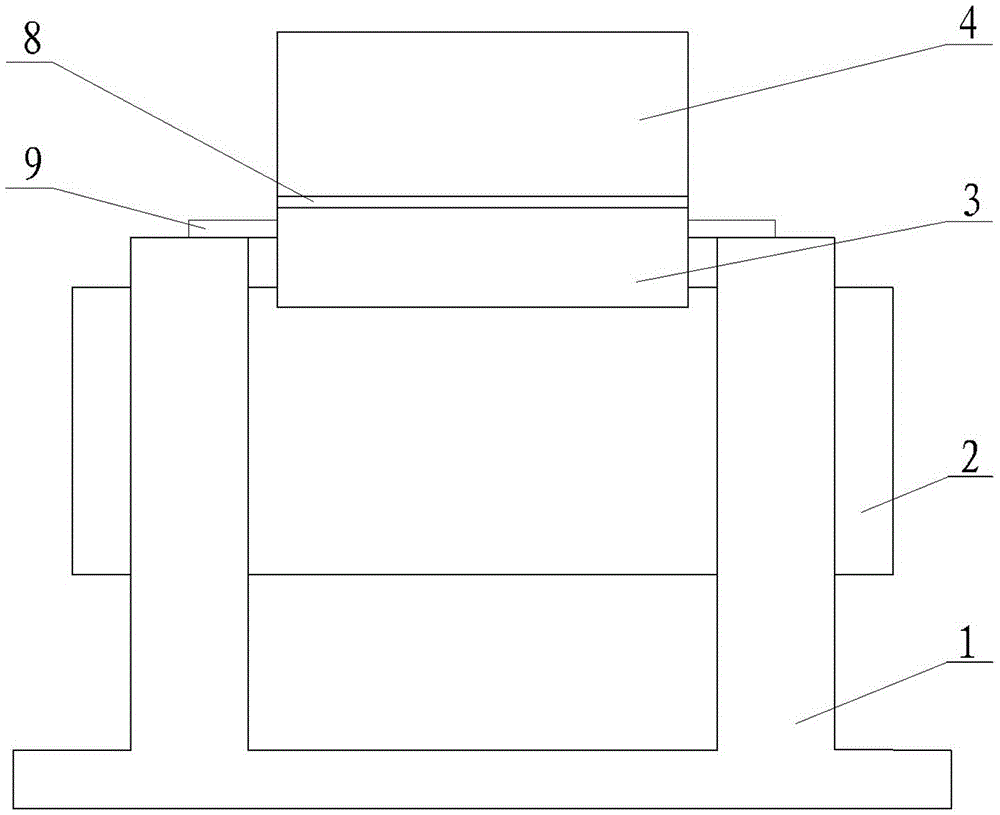

A short-process rolling forming device and method for a three-layer metal composite plate

A metal clad plate, short process technology, applied in metal rolling and other directions, can solve the problems of many production processes, high material and energy consumption, long process flow, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

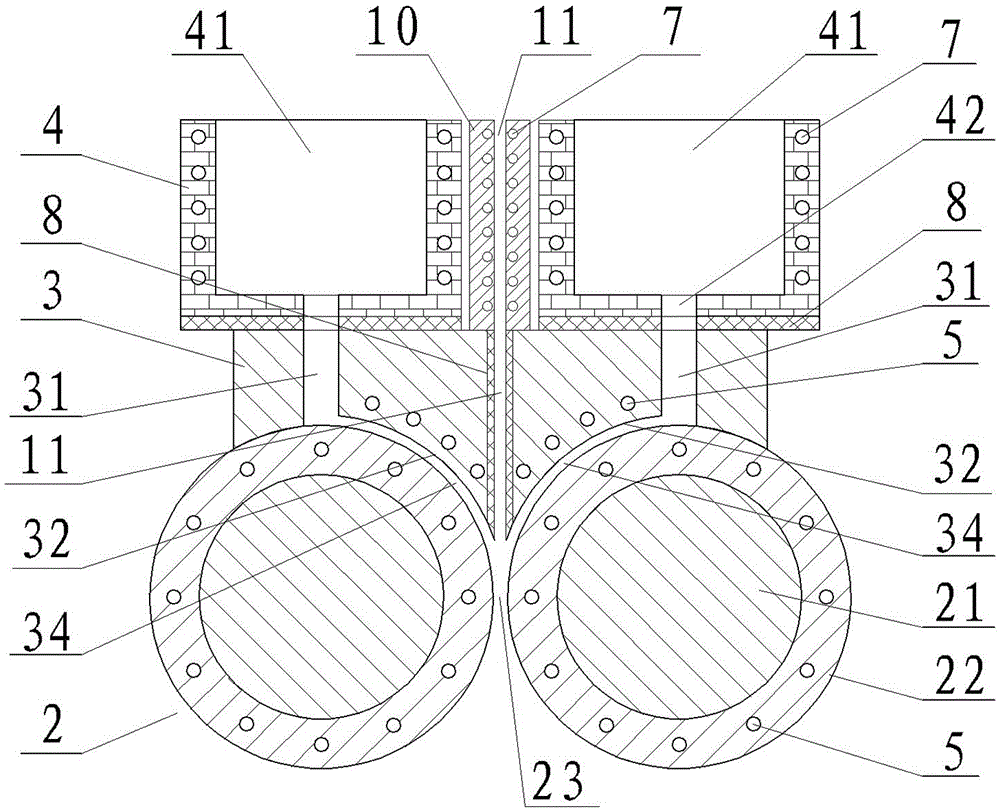

Method used

Image

Examples

Embodiment 1

[0043] Adopt the present invention to produce 4005 / 3003 / 4005 three-layer aluminum alloy composite board. This three-layer aluminum alloy composite board has the advantages of good welding performance of 4005 aluminum alloy and good corrosion resistance of 3003 aluminum alloy. It is often used in the manufacture of automobiles, electronics, Heat exchangers for electrical appliances, etc., as follows:

[0044] Step 1: Clean the surface of the core layer 3003 aluminum alloy plate to remove oil stains and scale on the surface;

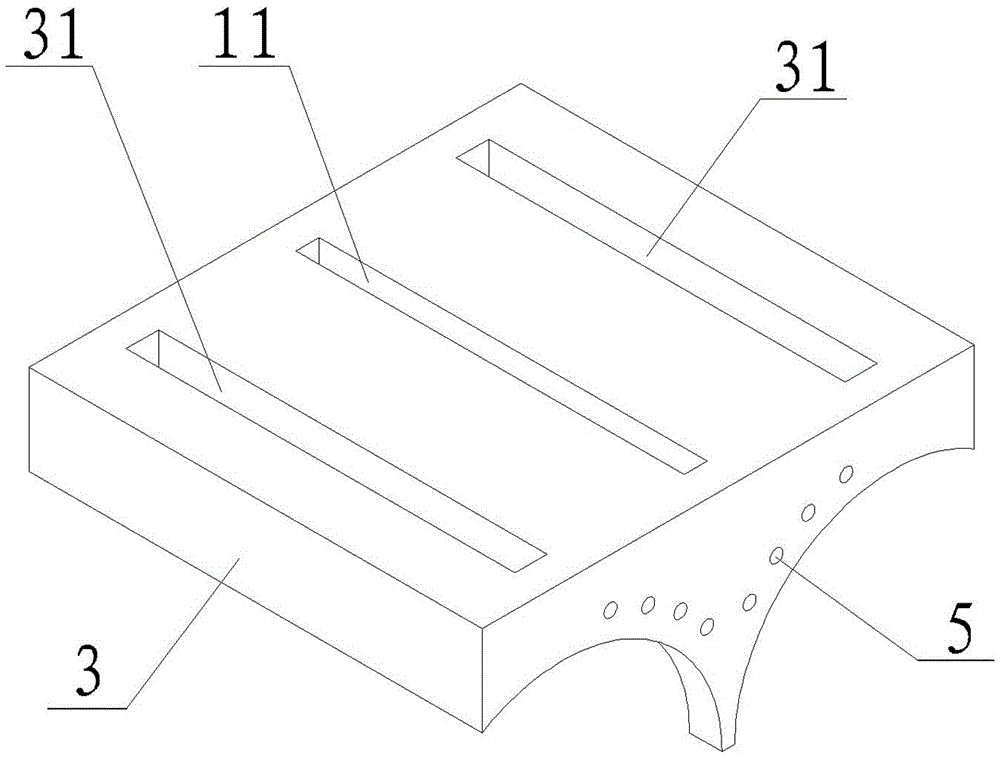

[0045] Step 2: Pass the core layer 3003 aluminum alloy plate through the rectangular channel on the preheating device and the rectangular channel on the crystallizer in turn, and finally reach the gap between the two rolls, and then turn on the power of the preheating device to heat the core layer The metal plate is preheated, and the preheating temperature is 200°C;

[0046] Step 3: Heat and melt the 4005 aluminum alloy liquid in a resistance melting fur...

Embodiment 2

[0051] Adopt the present invention to produce 4005 / 3003 / 7002 three-layer aluminum alloy composite board, this kind of three-layer aluminum alloy composite board has the advantages of good welding performance of 4005 aluminum alloy, 7002 aluminum alloy and good corrosion resistance of 3003 aluminum alloy, and is also commonly used in Manufacture heat exchangers for automobiles, electronics, electrical appliances, etc., as follows:

[0052] Step 1: Clean the surface of the core layer 3003 aluminum alloy plate to remove oil stains and scale on the surface;

[0053] Step 2: Pass the core layer 3003 aluminum alloy plate through the rectangular channel on the preheating device and the rectangular channel on the crystallizer in turn, and finally reach the gap between the two rolls, and then turn on the power of the preheating device to heat the core layer The metal plate is preheated, and the preheating temperature is 200°C;

[0054] Step 3: Heat and melt 4005 aluminum alloy liquid ...

Embodiment 3

[0059] Adopt the present invention to produce steel / aluminum / steel three-layer metal composite board, steel is 304 stainless steel, aluminum is 6063 aluminum alloy, this kind of steel / aluminum / steel three-layer metal composite board is usually used in the manufacture of high-end cooking utensils such as oil-free pan, electric cooker, etc. The bottom of the pot has the advantages of uniform heat transfer, safety and environmental protection. The method is as follows:

[0060] Step 1: Clean the surface of the 6063 aluminum alloy plate on the core layer to remove oil and scale on the surface;

[0061] Step 2: Pass the core layer 6063 aluminum alloy plate through the rectangular channel on the preheating device and the rectangular channel on the crystallizer in turn, and finally reach the gap between the two rolls, and then turn on the power of the preheating device to heat the core layer The metal plate is preheated, and the preheating temperature is 150°C;

[0062] Step 3: Heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com