Optical disc

A technology of optical discs and light reflection films, applied in optical discs, optical recording carriers, optical recording systems, etc., can solve problems such as recording/reproducing failures, achieve reduced jitter values, excellent recording/reproducing characteristics, and wide recording power margins Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

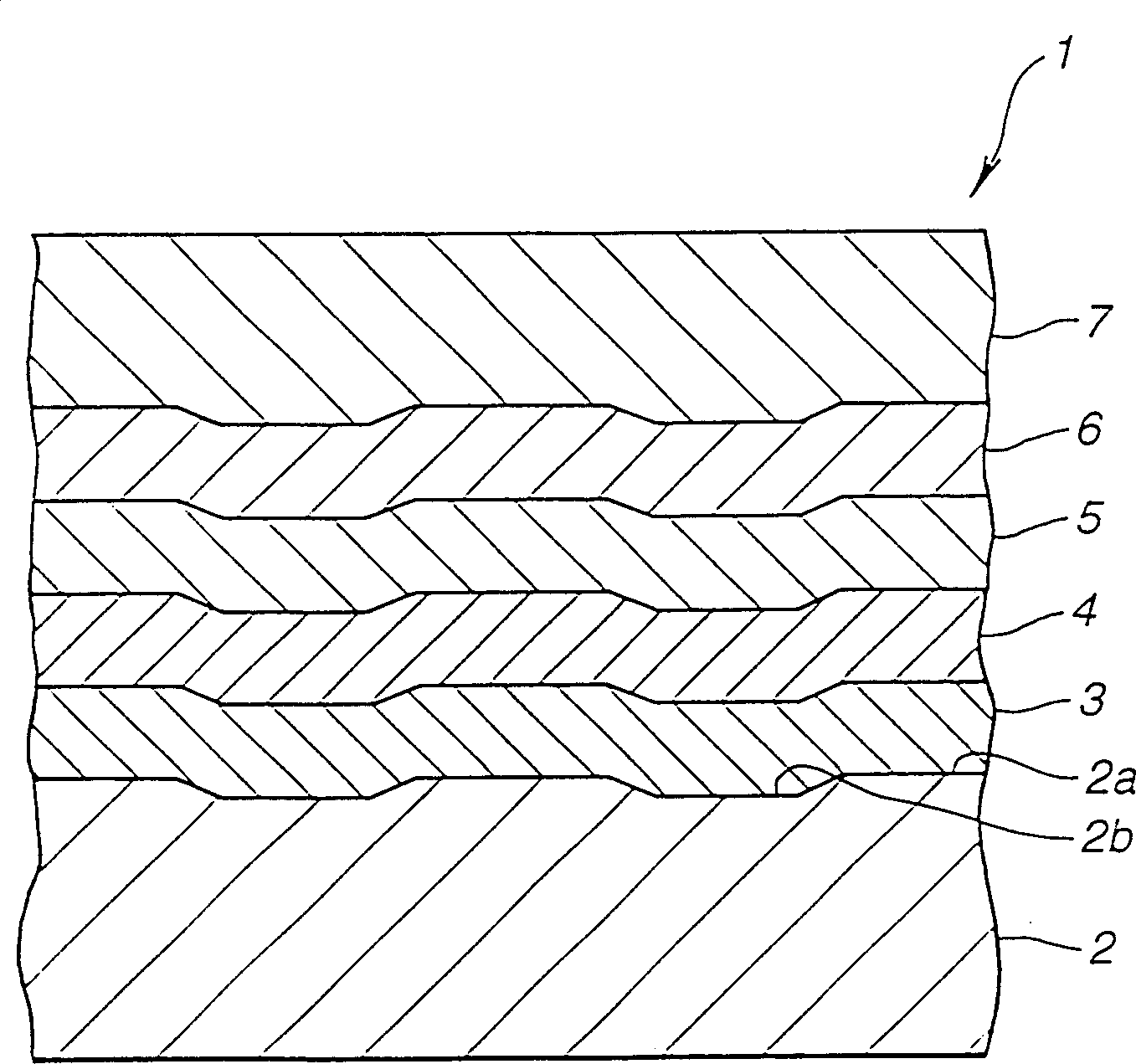

[0074] First, a substrate having a diameter of 120 mm, a thickness of 0.6 mm, and a track pitch of 0.8 µm was prepared.

[0075] Secondly, on this substrate, a 90nm thick ZnS-SiO 2 the first dielectric film.

[0076] Then, use sputtering method on this first dielectric film, use Ge 2 Sb 2 Te 5 target, and a phase-change recording film was formed in an Ar atmosphere.

[0077] Then, a 15nm thick ZnS-SiO film was made by sputtering on the phase change recording film. 2 the second dielectric film.

[0078] Then, on the second dielectric film, an Al 98 Cu 2 target and an Al target to make a light reflective film. This sputtering method is used to obtain Al with a thickness of 15nm and a Cu content of 0.5 atomic percent. 95.5 Cu 0.5 alloy film. Here, the Cu content is controlled by changing the Al 98 Cu 2 target and Al target film formation speed.

[0079] Then, this light reflection film is covered with an ultraviolet curable resin by spin coating, thus obtaining a sin...

example 2

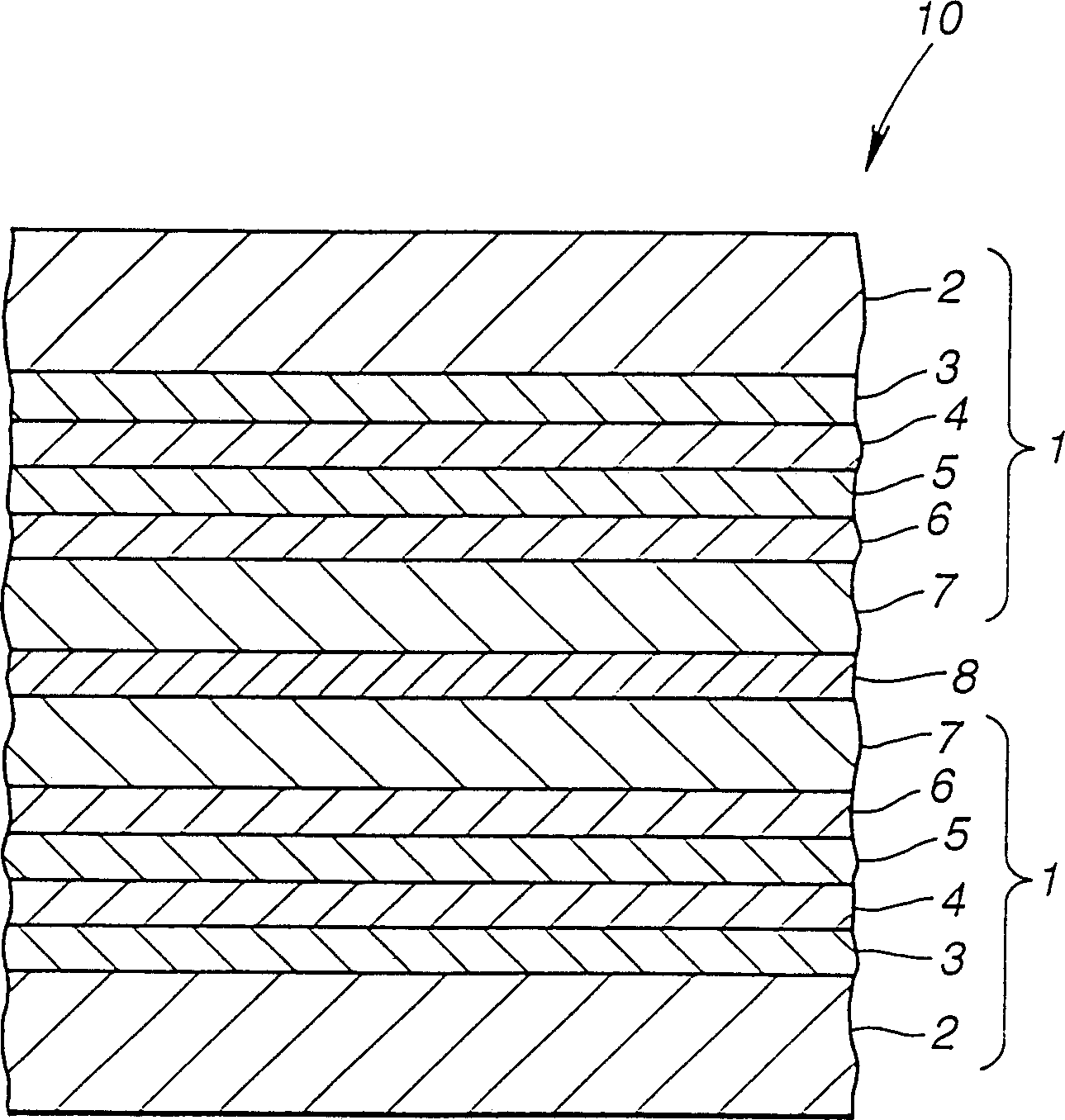

[0100] In addition to changing Al 98 Cu 2 In addition to the film forming speed of the target and the Al target, a light reflective film is produced, and a double-sided phase change optical disc is prepared in the same way as Example 1, so that the thickness of the light reflective film obtained is 15nm, and the composition is that the Cu content is 0.75 atomic percent. Al 99.25 Cu 0.75 alloy.

[0101] Comparative example 2

[0102] In addition to changing Al 98 Cu 2 In addition to the film forming speed of the target and the Al target, a light reflective film is produced, and a double-sided phase change disc is prepared by the same method as in Example 1, so that the thickness of the light reflective film obtained is 15nm, and the composition is that the Cu content is 0.1 atomic percent. Al 99.9 Cu 0.1 alloy.

[0103] Comparative example 3

[0104] In addition to changing Al 98 Cu 2 In addition to the film forming speed of the target and the Al target, a double-si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com