Efficient flushing pedestal pan

A toilet, high-efficiency technology, applied in the field of sanitary equipment, can solve the problems of insufficient use of instantaneous energy, low water kinetic energy, unsatisfactory flushing effect, etc., and achieves high utilization efficiency, easy flushing control, and ensure the effect of normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

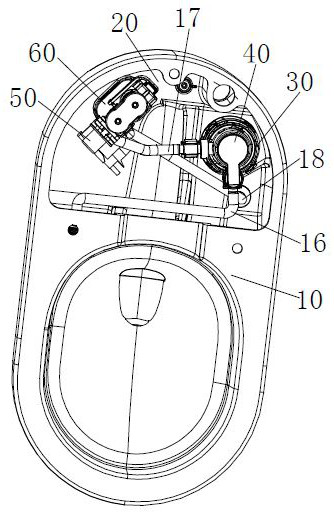

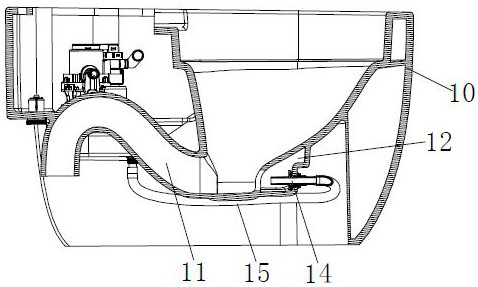

[0051] As shown in the figure, the water tank 20 is further provided with a water pump 50 , and the water pump 50 is used for pumping the water stored in the water tank 20 to supply the hydraulic drive mechanism 40 . Specifically, the water outlet of the water pump 50 is connected to the water inlet 41 through the connecting pipe 17 . That is, in this embodiment, the external pressure water source is to pump the water in the water tank through the water pump 50 . Further, the water tank 20 is also provided with a water inlet valve 60. The water inlet valve 60 has a second outlet 64 and a first outlet 63 for flowing water into the water tank 20. The water outlet from the second outlet 64 is preferably controlled by a solenoid valve. , the water from the first outlet 63 is controlled by a buoy 65 or through an electronically controlled valve, and the water from the second outlet 64 is connected to the outlet of the jet pipe 12, so that the water discharged from the water outlet ...

Embodiment 2

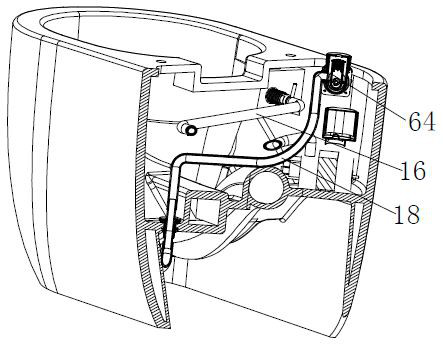

[0054] As shown in the figure, the water tank 20 also includes a water inlet valve 60. The water inlet valve 60 has a second outlet 64 and a first outlet 63 for flowing water into the water tank 20. The water from the first outlet 63 passes through a The buoy 65 is controlled or controlled by an electric control valve, and the water output from the second outlet 64 is controlled by a switch assembly. The second outlet 64 is connected to the water inlet 41 through the connecting pipe 17 . That is, in this embodiment, the external pressure water source is the tap water of the municipal water supply pipe network. In this embodiment, the water outlet 42 is also connected to the outlet of the jetting pipe 12. Specifically, the bottom wall of the water tank is provided with a waterway connecting head, the water outlet 42 is connected to the waterway connecting head through the connecting pipe 18, and the outlet of the jetting pipe 12 A spray connection assembly 14 is installed near...

Embodiment 3

[0057] As shown in the figure, the main difference between this embodiment and the second embodiment is:

[0058] First, the water tank 20 is further provided with a water pump 50 , and the water pump 50 is used to extract the water stored in the water tank 20 to supply the hydraulic drive mechanism 40 . Therefore, the hydraulic drive mechanism 40 has another water inlet besides the water inlet 41, and the water outlet of the water pump 50 is connected to the other water inlet through the connecting pipe 17'. That is, in this embodiment, the external pressure water source can be either the water in the water tank pumped through the water pump 50 or the tap water from the municipal water supply pipe network. Therefore, a first check valve 90 is arranged between the second outlet 64 and the water inlet 41, and a second check valve 90' is arranged between the water outlet of the water pump 50 and the other water inlet, so that the The water flowing into the hydraulic chamber 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com