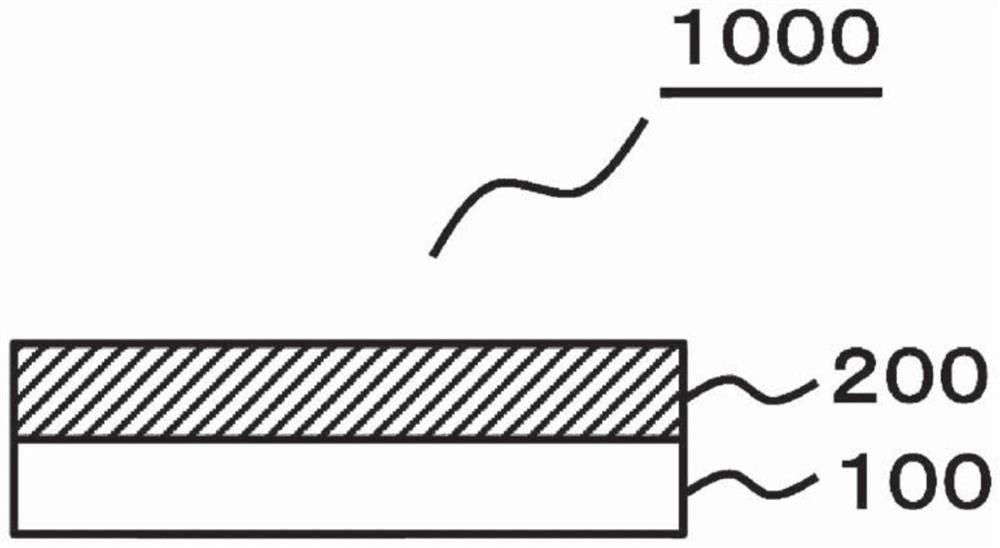

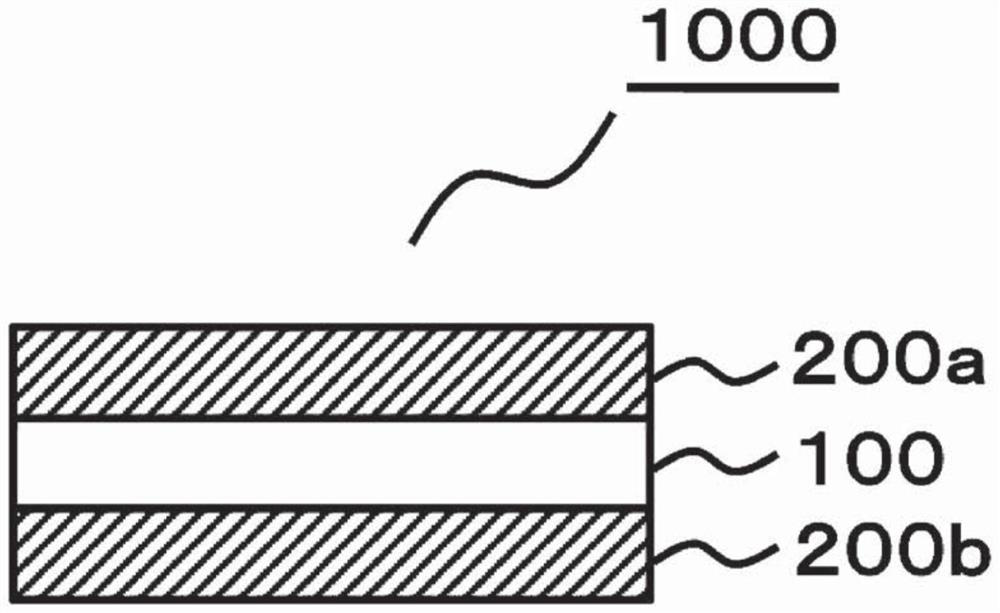

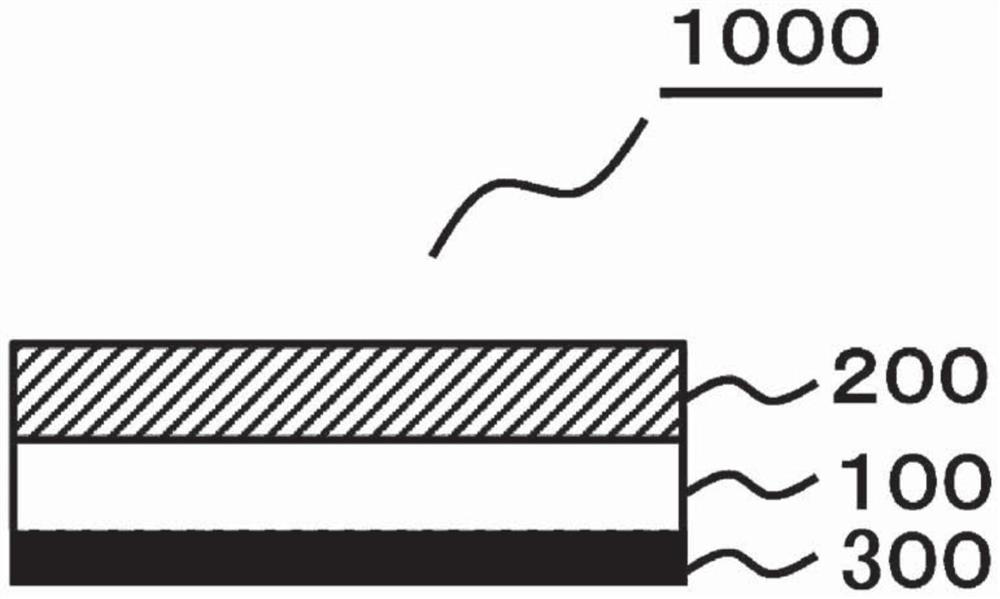

Adhesive tape

A technology of adhesive tape and adhesive layer, applied in the direction of adhesive, film/sheet adhesive, coating, etc., can solve the problems of easy wrinkling, warping, thinning of adhesive tape, etc., to achieve Excellent unevenness followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0207] Into a reaction vessel equipped with a stirrer, a thermometer, a nitrogen introduction pipe, and a condenser, as monomer components, 2-ethylhexyl acrylate (2EHA): 30 parts, n-butyl acrylate (BA): 70 parts, acrylic acid ( AA): 2 parts, and 4-hydroxybutyl acrylate (4HBA): 0.1 part, 2,2'-azobisisobutyronitrile (AIBN) as a polymerization initiator: 0.08 part, and toluene as a polymerization solvent: 150 parts were solution-polymerized at 65 degreeC for 8 hours, and the toluene solution of an acrylic polymer (A) was obtained. The weight average molecular weight of this acrylic polymer (A) was 440,000.

[0208] With respect to 100 parts of acrylic polymer (A) contained in the above-mentioned toluene solution, tackifier resin TA (manufactured by Harima Chemical Co., Ltd., hydrogenated rosin glyceride, trade name "HARITACK SE10", softening point: 75°C was added ~85°C): 30 parts, and an isocyanate-based crosslinking agent (manufactured by Tosoh Corporation, trade name "CORONATE...

Embodiment 2

[0213] Except having changed the usage-amount of the isocyanate-based crosslinking agent (manufactured by Tosoh Corporation, trade name: "CORONATE L") to 1.8 parts, it was carried out in the same manner as the preparation of the adhesive composition (A) in Example 1, Thereby, the adhesive composition (B) was prepared.

[0214] Two commercially available release liners (manufactured by Sumika Paper Co., Ltd., trade name "SLB-80WD (#1300)" (double-sided release liner with release-treated layer) were prepared. The said adhesive composition (B) was apply|coated on one surface (release surface) of each release liner so that the thickness after drying might be 20 micrometers, and it dried at 100 degreeC for 5 minutes. As a result, a 20-μm-thick pressure-sensitive adhesive layer (first pressure-sensitive adhesive layer) composed of the acrylic pressure-sensitive adhesive (B) corresponding to the pressure-sensitive adhesive composition (B) was formed on the release surfaces of the abo...

Embodiment 3

[0218] It carried out similarly to Example 1, and produced the adhesive composition (A).

[0219] Two commercially available release liners (manufactured by Sumika Paper Co., Ltd., trade name "SLB-80WD (#1300)" (double-sided release liner with release-treated layer) were prepared. The said adhesive composition (A) was apply|coated on one surface (release surface) of each release liner so that the thickness after drying might be 10 micrometers, and it dried at 100 degreeC for 5 minutes. As a result, a 10-μm-thick pressure-sensitive adhesive layer (first pressure-sensitive adhesive layer (first) composed of the acrylic pressure-sensitive adhesive (A) corresponding to the pressure-sensitive adhesive composition (A) was formed on the release surfaces of the above-mentioned two release liners, respectively. adhesive layer and second adhesive layer).

[0220] An ether-type urethane resin film (B) (100% modulus=5.6 MPa) having a thickness of 30 μm was prepared as a base material lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com