Adhesives and Adhesive Sheets

A technology of adhesives and adhesive sheets, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of insufficient cohesion, low adhesion, foaming, low heat resistance, etc., to achieve Excellent effect of irregularity followability and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] 1. Modulation of Polymer (A1)

[0135] Into the reaction vessel equipped with a stirrer, a thermometer, a circulating cooler, a dropping device and a nitrogen introduction pipe, add 76.5 parts by mass of n-butyl acrylate, 20 parts by mass of methoxyethyl acrylate, and 3.0 parts by mass of acrylic acid. 0 parts by mass, 0.5 parts by mass of 2-hydroxyethyl acrylate, 200 parts by mass of ethyl acetate, and 0.08 parts by mass of 2,2'-azobisisobutyronitrile. Replace with nitrogen. While stirring under this nitrogen atmosphere, the temperature of the reaction solution was raised to 60° C., and after reacting for 16 hours, it was cooled to room temperature. Here, a part of the obtained solution was measured for molecular weight by the following method, and the generation of the polymer (A1) with a weight average molecular weight of 800,000 was confirmed.

[0136] 2. Modulation of Polymer (B1)

[0137] Into a reaction vessel equipped with a stirrer, a thermometer, a circul...

Embodiment 2

[0149] 2-methacryloyloxyethyl isocyanate (MOI), which is a polymerizable double bond-containing compound (b2), is reacted with a (meth)acrylic polymer (b1). At this time, the amount of isocyanate groups in the MOI is The HEA of the (meth)acrylic polymer (b1) was 0.2 molar equivalent. Except for this, the polymer (B2) was produced in the same manner as the polymer (B1) in Example 1. Part of the obtained solution was measured for molecular weight by the following method, and the generation of a polymer (B2) with a weight average molecular weight of 50,000 was confirmed.

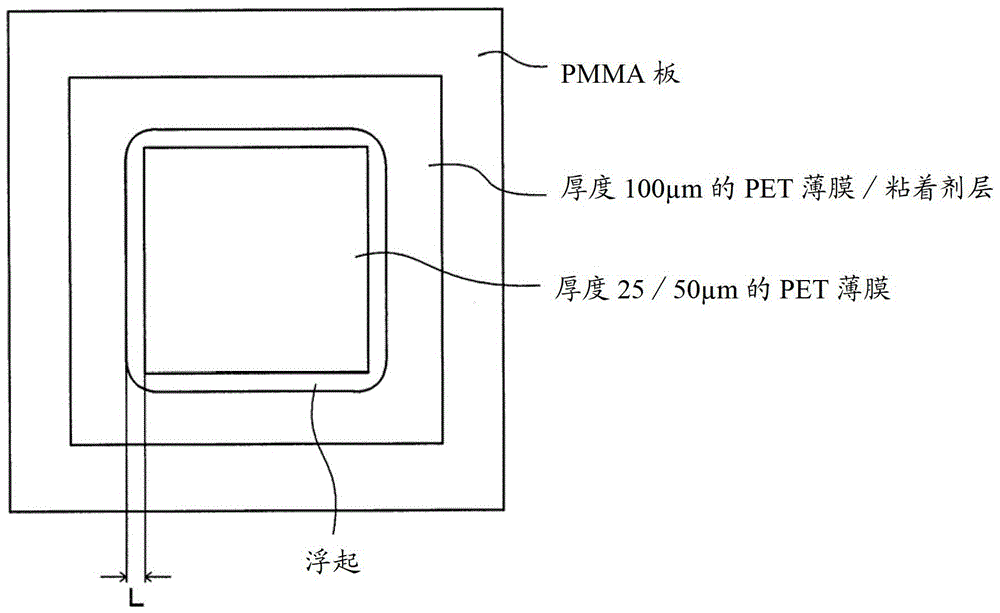

[0150] Except having replaced the polymer (B1) with the polymer (B2), it carried out similarly to Example 1, and prepared the adhesive composition, and manufactured the polarizing plate which has an adhesive layer using this adhesive composition. In addition, the thickness of the adhesive layer was 25 μm.

Embodiment 3

[0151] [Example 3, Comparative Examples 1-3]

[0152] Except having changed the kind and compounding quantity of a polymer (B) as shown in Table 1, it carried out similarly to Example 1, and manufactured the polarizing plate which has an adhesive layer. In addition, the thickness of the adhesive layer was 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com