Adhesive composition, adhesive sheet, and touch panel and display device having the adhesive sheet

A composition and adhesive technology, which is applied in the direction of adhesive type, ester copolymer adhesive, film/sheet adhesive, etc., can solve the problems of low concave-convex followability, step residual bubbles, etc., and achieve The effect of suppressing the generation of delayed bubbles, suppressing delayed bubbles, and excellent unevenness followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

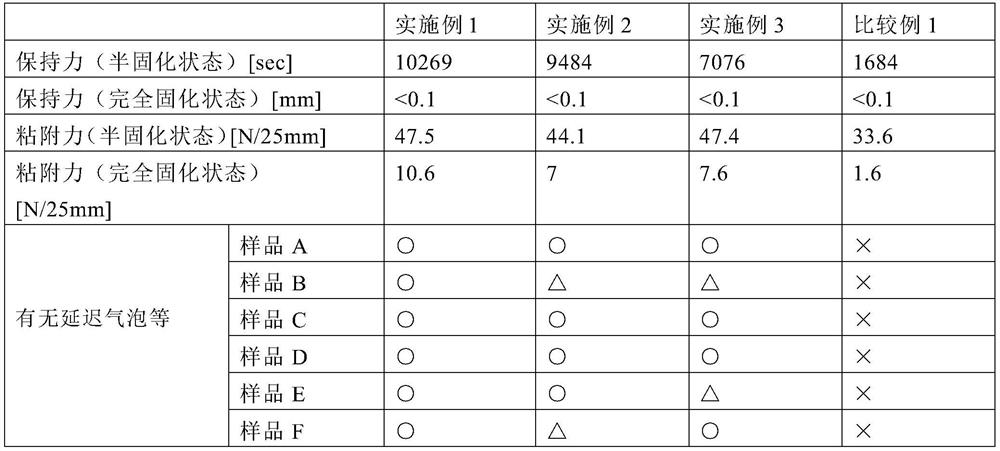

Embodiment 1

[0056] (Preparation of Coating Solution)

[0057] First, 100 parts by weight of an acrylate copolymer (A) with a weight average molecular weight of 450,000 and a hydroxyl value of 90 to 100 was diluted with 44 parts by weight of a solvent, and then the oligomer (B), monomer (C), The crosslinking agent (D) and the photopolymerization initiator (E) are sufficiently stirred to prepare a coating liquid (adhesive solution) consisting of an adhesive composition and a solvent. Here, ethyl acetate was used as a solvent. Moreover, the model number "UF-8001G" by Kyoeisha Chemical Co., Ltd. was used as an oligomer (B), and 2.2 weight part was added with respect to 100 weight part of acrylate copolymers (A). 2-isocyanatoethyl methacrylate (2-isocyanate) was used as the monomer (C), and 0.11 parts by weight was added to 100 parts by weight of the acrylate copolymer (A). Moreover, the Tosoh Corporation (Tosoh Corporation) model "Coroneto HX" was used as a crosslinking agent (D), and 0.088...

Embodiment 2

[0061] Example 2 was produced in the same manner as in Example 1, except that 6.6 parts by weight of the oligomer (B) in Example 1 was added to 100 parts by weight of the acrylate copolymer (A). Adhesive sheet samples.

Embodiment 3

[0063] Example 3 was produced in the same manner as in Example 1, except that 11 parts by weight of the oligomer (B) in Example 1 was added to 100 parts by weight of the acrylate copolymer (A). Adhesive sheet samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com