Adhesive sheet and laminate

A technology for adhesive sheets and laminates, applied in the direction of adhesives, layered products, polyether adhesives, etc., can solve problems such as reflection loss of light, achieve corrosion inhibition, excellent uneven tracking, and resistance to humidity and heat whitening Excellent performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

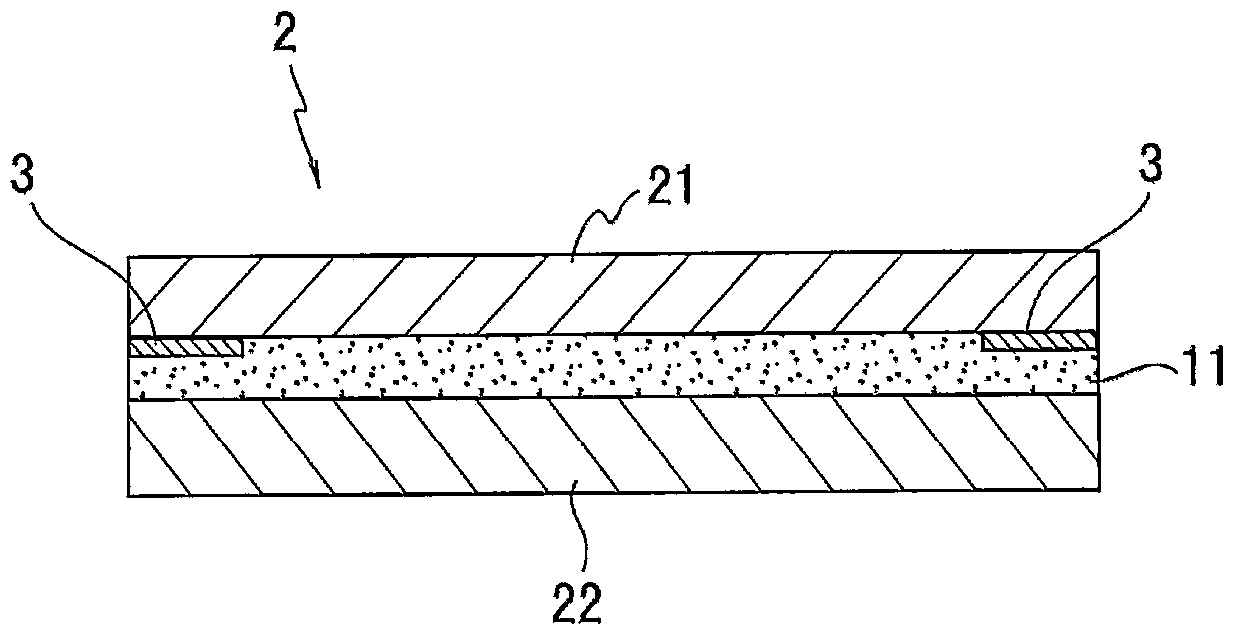

[0101] As another example of producing the adhesive sheet 1, the coating liquid of the above-mentioned adhesive composition P is applied on the release surface of one release sheet 12a, and heat-treated to thermally crosslink the adhesive composition P to form a coating. cloth layer to obtain a release sheet 12a with a coating layer. In addition, the coating liquid of the above-mentioned adhesive composition P is coated on the release surface of the other release sheet 12b, and heat-treated to thermally crosslink the adhesive composition P to form a coating layer, thereby obtaining a coated layer. Release sheet 12b for the cloth layer. Then, the release sheet 12a with a coating layer and the release sheet 12b with a coating layer are bonded so that both coating layers may contact. When the aging period is required, the aging period is provided; when the aging period is not required, the above-mentioned laminated coating layer becomes the adhesive layer 11 as it is. Thus, the...

Embodiment 1

[0140] 1. Preparation of (meth)acrylate copolymer

[0141] A (meth)acrylate copolymer (A) was prepared by copolymerizing 60 parts by mass of 2-ethylhexyl acrylate, 20 parts by mass of methyl methacrylate, and 20 parts by mass of 2-hydroxyethyl acrylate. When the molecular weight of this (meth)acrylate copolymer (A) was measured by the method mentioned later, the weight average molecular weight was 700,000.

[0142] 2. Preparation of adhesive composition

[0143] 100 parts by mass of the (meth)acrylate copolymer (A) obtained in the above step (1) (solid content conversion value; the same below), polyethylene glycol diethylene glycol as the active energy ray-curable component (B) Acrylate (manufactured by Shin-Nakamura Chemical Co., Ltd., trade name "NK ESTER A-400") 5 parts by mass, trimethylolpropane-modified toluene diisocyanate (manufactured by Nippon Polyurethane Industry Co., Ltd., Trade name "CORONATE L") 0.23 parts by mass, 3-(2,3-glycidoxy)propyltrimethoxysilane (manu...

Embodiment 2~9

[0158] [Examples 2-9, Comparative Examples 1-3]

[0159]In addition to the proportion of each monomer constituting the (meth)acrylate copolymer (A), the weight average molecular weight of the (meth)acrylate copolymer (A), the type and compounding of the active energy ray-curable component (B), The amount, the compounding amount of the crosslinking agent (C), the compounding amount of the photopolymerization initiator (D), the compounding amount of the silane coupling agent, and the thickness of the adhesive layer were changed according to Table 1, and the same as in Example 1 An operation is performed to manufacture an adhesive sheet. In addition, in Example 7, the thickness of each coating layer of the heavy release type release sheet with a coating layer and the light release type release sheet with a coating layer was 75 μm, and the thickness of the adhesive layer was 150 μm. Make adhesive sheets.

[0160] Here, the above-mentioned weight average molecular weight (Mw) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com