Preparation method of casting blank for copper-silver alloy wire suitable for ultra-fine drawing

A copper-silver alloy, ultra-fine technology, applied in the direction of casting molding equipment, metal processing equipment, metal/alloy conductors, etc., can solve the problems of limited processing volume, limited outer diameter of billets, and reduction of pores, inclusions, and looseness of billets , to achieve the effect of reducing defects such as pores, inclusions and slag inclusions, and improving the uniformity of the structure and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

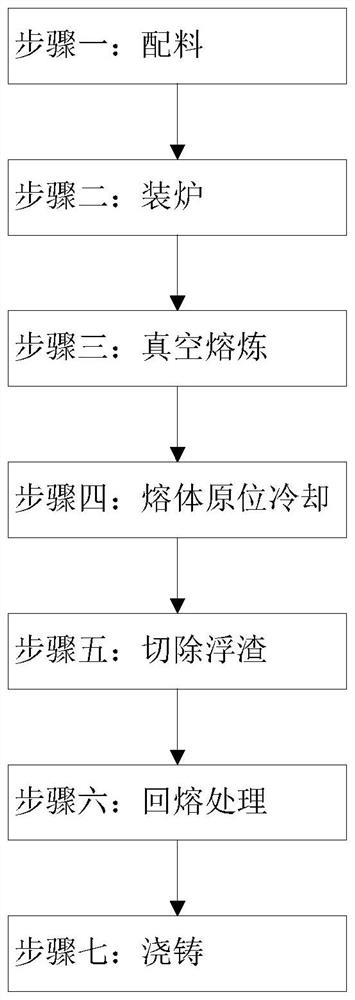

[0029] The embodiment of the present invention provides a method for preparing a copper-silver alloy wire casting billet suitable for ultra-fine drawing, and the specific steps are as follows:

[0030] Step 1: Weigh the required raw materials according to the alloy mass percentage, and degreasing, cleaning, drying, and refining rare earth yttrium for impurity removal, weighing 0.06% of the total mass of copper and silver, in the form of copper-rare earth master alloy Add, the adopted raw material and its proportion are as shown in table 1:

[0031] Table 1: Raw materials and their proportions

[0032] raw material purity mass percentage pure copper ≥99.95% margin Sterling silver ≥99.95% 1.5% Copper yttrium master alloy Contains Y: 12% 0.06% (based on Y content)

[0033] Step 2: Load the furnace, first load the silver nuggets, spread them to the bottom of the crucible, then load the electrolytic copper nuggets, and add the copper-rare ...

Embodiment 2

[0040] This embodiment provides another method for preparing a copper-silver alloy wire casting billet suitable for ultra-fine drawing, and the specific steps are as follows:

[0041] Step 1: Weigh the required raw materials according to the alloy mass percentage, and degreasing, cleaning, drying, and refining rare earth yttrium for impurity removal, weighing 0.04% of the total mass of copper and silver, in the form of copper-rare earth master alloy Add, the raw material adopted and its proportioning are as shown in table 2:

[0042] Table 2: Raw materials and their proportions

[0043] raw material purity mass percentage pure copper ≥99.95% margin Sterling silver ≥99.95% 4.5% Copper yttrium master alloy Contains Y: 12% 0.04% (based on Y content)

[0044] Step 2: Load the furnace, first load the silver nuggets, spread them to the bottom of the crucible, then load the electrolytic copper nuggets, and add the copper-rare earth intermedi...

Embodiment 3

[0051] This embodiment provides another method for preparing a copper-silver alloy wire casting billet suitable for ultra-fine drawing, which specifically includes the following:

[0052] Step 1: Weigh the required raw materials according to the alloy mass percentage, and degreasing, cleaning, drying, refining the rare earth yttrium for removing impurities, weighing 0.02% of the total mass of copper and silver, in the form of copper-rare earth master alloy Add, the adopted raw material and its proportioning are as shown in table 2:

[0053] Table 3: Raw materials and their proportions

[0054] raw material purity mass percentage pure copper ≥99.95% margin Sterling silver ≥99.95% 8.5% Copper yttrium master alloy Contains Y: 12% 0.02% (based on Y content)

[0055] Step 2: Load the furnace, first load the silver nuggets, spread them to the bottom of the crucible, then load the electrolytic copper nuggets, and add the copper-rare earth in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com