Glass powder for PERC cell back silver paste and preparation method thereof

A glass powder and backside technology, applied in the field of conductive paste, can solve the problems of glass transition temperature of glass powder, inability to directly form glass, and high melting point of titanium oxide, so as to improve the photoelectric conversion efficiency and electrode reliability, and improve the battery Fill factor, effect of low softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In a specific embodiment, the preparation method of the glass powder for silver paste on the back of the PERC cell includes:

[0038] Add the tetrabutyl titanate-ethanol solution dropwise to the glass powder-acetic acid solution, keep stirring during the dropping process, continue to stir for 30 to 60 minutes after the dropwise addition, separate the solid and liquid, wash and dry to obtain the silver paste on the back of the PERC battery. Glass powder; the mass ratio of the tetrabutyl titanate-ethanol solution:glass powder-acetic acid solution is preferably 100:40-90.

[0039] The glass powder in the glass powder-acetic acid solution is the above-mentioned core Bi 2 O 3 -PbO-SiO 2-CuO-MnO system.

[0040] In a specific embodiment, the tetrabutyl titanate-absolute ethanol solution is a mixture of anhydrous ethanol and tetrabutyl titanate, and the mass ratio of the tetrabutyl titanate: anhydrous ethanol is preferably 5 ~10:100.

[0041] In a specific embodiment, the...

Embodiment 1

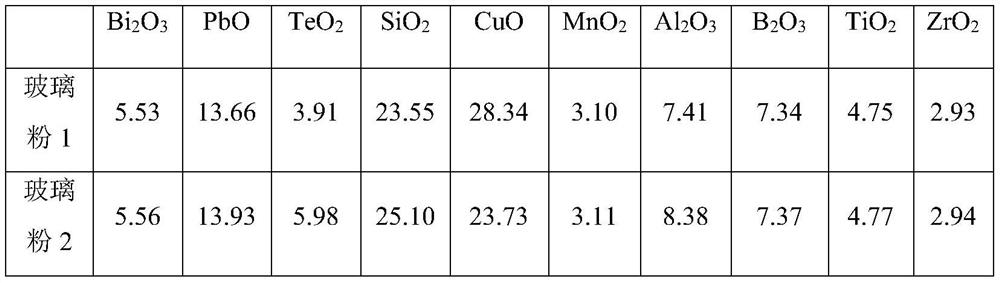

[0053] Take D50 as 5 g of 1.3 μm glass powder 1 (the specific components are in the following table), add 100 g of deionized water, use anhydrous acetic acid to adjust the pH value to 4, stir, and record it as suspension A;

[0054] Table 1 Glass powder composition (in parts by mass)

[0055]

[0056] Take 10 g of tetrabutyl titanate, dissolve it in 100 g of absolute ethanol, and record it as solution B;

[0057] 100g of solution B was added to 80g of solution A at a temperature of 20°C-30°C at 1ml / s, stirring was continued during the addition, and the stirring rate was 400r / min. After the addition was completed, stirring was continued for 0.5h. After the reaction was completed, the supernatant was poured, and the lower layer of titanium oxide@glass powder composite powder was removed, washed 4 times with deionized water and absolute ethanol, and dried in a 50°C oven to obtain 5.1g of titanium oxide@glass powder 1, The content of titanium oxide in the titanium oxide@glass ...

Embodiment 2

[0059] Take D50 as 5 g of 1.3 μm glass powder 1 (specific components are shown in Table 1), add 100 g of deionized water, use anhydrous acetic acid to adjust the pH value to 5, stir, and record it as suspension A;

[0060] Take 10 g of tetrabutyl titanate, dissolve it in 100 g of absolute ethanol, and record it as solution B;

[0061] 100g of solution B was added to 80g of solution A at a temperature of 20°C-30°C at 2ml / s. During the addition, stirring was continued at a stirring rate of 400r / min. After the addition was completed, stirring was continued for 0.5h. After the reaction was completed, the supernatant was poured, and the lower layer of titanium oxide@glass powder composite powder was removed, washed 4 times with deionized water and absolute ethanol respectively, and dried in a 50°C oven to obtain 5.18g of titanium oxide@glass powder 2, The content of titanium oxide in titanium oxide@glass frit 2 is specifically about 3.6 wt %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com