Method for treating resin production wastewater based on combination of chemical precipitation and two-stage photocatalysis

A technology for chemical precipitation and production of wastewater, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage multi-stage treatment, etc. Complex process and other problems, to achieve good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

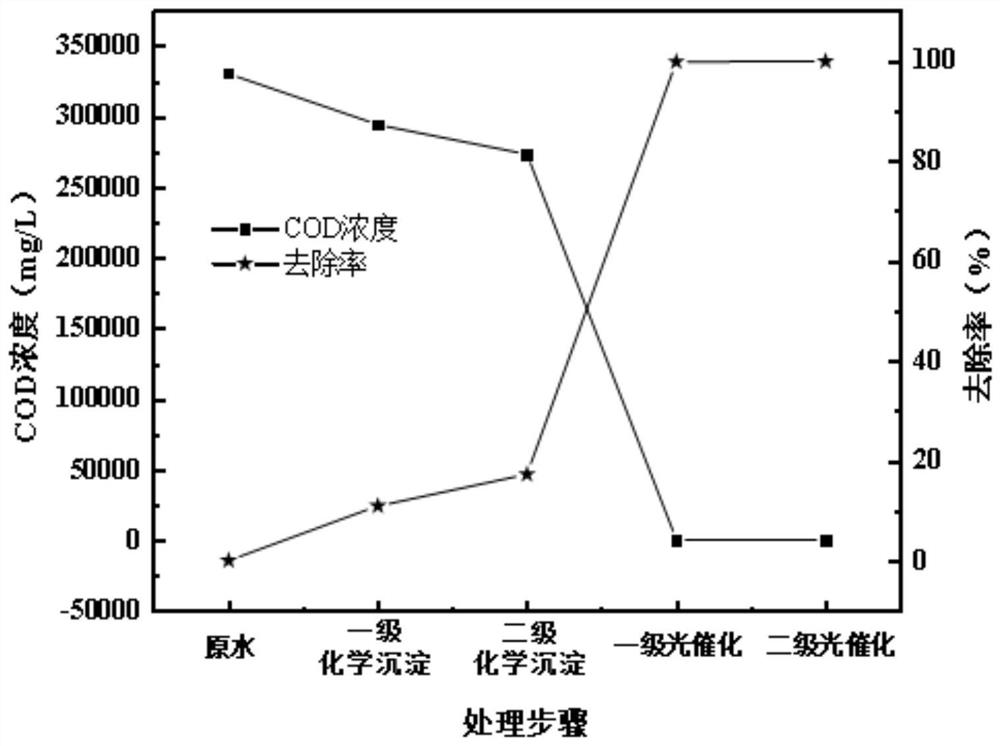

[0022] Embodiment 1: The method for treating resin production wastewater based on chemical precipitation combined with two-stage photocatalysis in this embodiment is carried out according to the following steps:

[0023] 1. First-grade chemical precipitation: add calcium hydroxide solid to the resin production wastewater to make the calcium hydroxide concentration reach 1.0g / L, stir and react for 70min, a precipitate is formed, and stand for 12 hours to obtain a first-grade supernatant;

[0024] 2. Secondary chemical precipitation: continue to add sodium hydroxide solid to the primary supernatant, so that the pH of the primary supernatant reaches 7, a precipitate is formed, and let stand for 12 hours to obtain the secondary supernatant;

[0025] 3. Primary photocatalytic treatment: use UV / H 2 O 2 The secondary supernatant is treated by photocatalytic oxidation, that is, hydrogen peroxide with a mass percentage concentration of 30% is added to the secondary supernatant, and th...

Embodiment 2

[0028] Embodiment 2: The method for treating resin production wastewater based on chemical precipitation combined with two-stage photocatalysis in this embodiment is carried out according to the following steps:

[0029] 1. First-level chemical precipitation: add calcium hydroxide solid to the resin production wastewater to make the calcium hydroxide concentration reach 0.8g / L, stir and react for 90min, a precipitate is formed, and stand for 12 hours to obtain a first-level supernatant;

[0030] 2. Secondary chemical precipitation: continue to add sodium hydroxide solid to the primary supernatant, so that the pH of the primary supernatant reaches 8, and precipitate is formed, and let stand for 16 hours to obtain the secondary supernatant;

[0031] 3. Primary photocatalytic treatment: use UV / H 2 O 2 The secondary supernatant is treated by the photocatalytic oxidation method, that is, hydrogen peroxide with a mass percentage concentration of 30% is added to the secondary supern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com