Preparation method and application of NiCu/SiO2 catalyst for efficiently catalyzing benzyl alcohol dehydrogenation to prepare benzaldehyde

A technology for catalyzing benzyl alcohol and catalysts, which is applied in the field of high-dispersion NiCu/SiO2 catalysts and its preparation, can solve the problems of poor dispersion effect, difficulty in further improving catalytic activity, and large amount of Ni added, and achieve low side reactions , high atom utilization, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

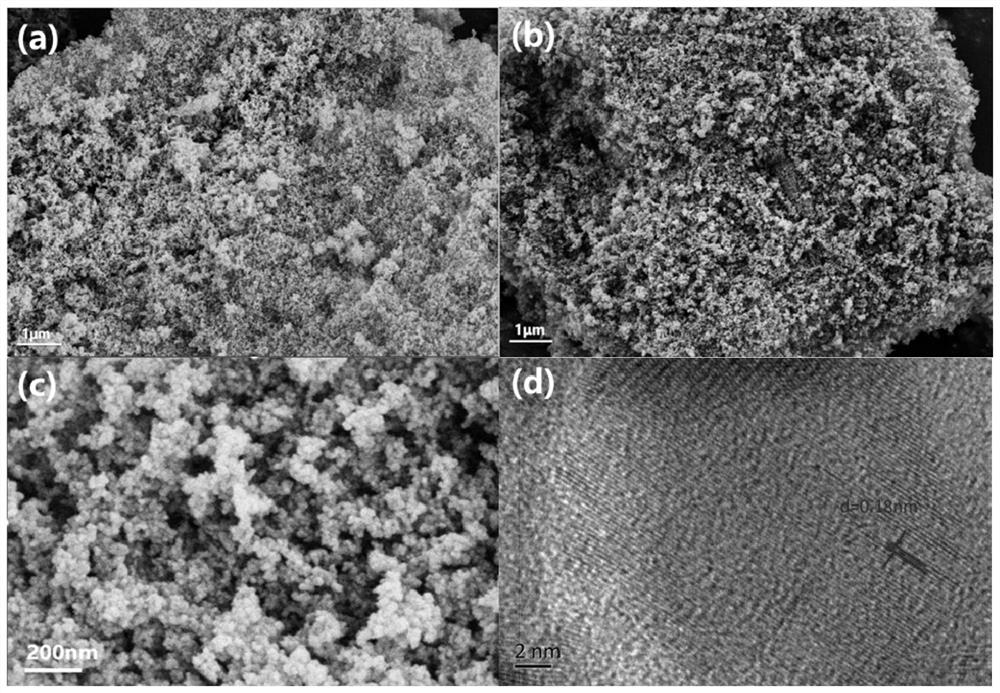

Embodiment 1

[0036] Under nitrogen protection and continuous stirring, an aqueous solution of ascorbic acid was added to a mixed aqueous solution of copper nitrate trihydrate and polyvinylpyrrolidone (PVP), wherein the molar ratio of copper nitrate to PVP was 200:1, and the ascorbic acid and copper nitrate were The mass ratio is 1:20. Then, the aqueous solution of sodium borohydride was added dropwise to the mixed solution, wherein the mass ratio of sodium borohydride to copper nitrate was 1:10, and it could be observed that the brown solid was continuously precipitated.

[0037] After calcining the fumed silica in a muffle furnace at 650 °C for 12 hours for pre-activation, the fumed silica is fully dispersed in water. The fumed silica suspension was added dropwise to the above three-necked flask, wherein the mass ratio of copper nitrate trihydrate to fumed silica was 5:2. After stirring continuously for 1 h, it was filtered and washed three times with deionized water, and the filter resi...

Embodiment 2

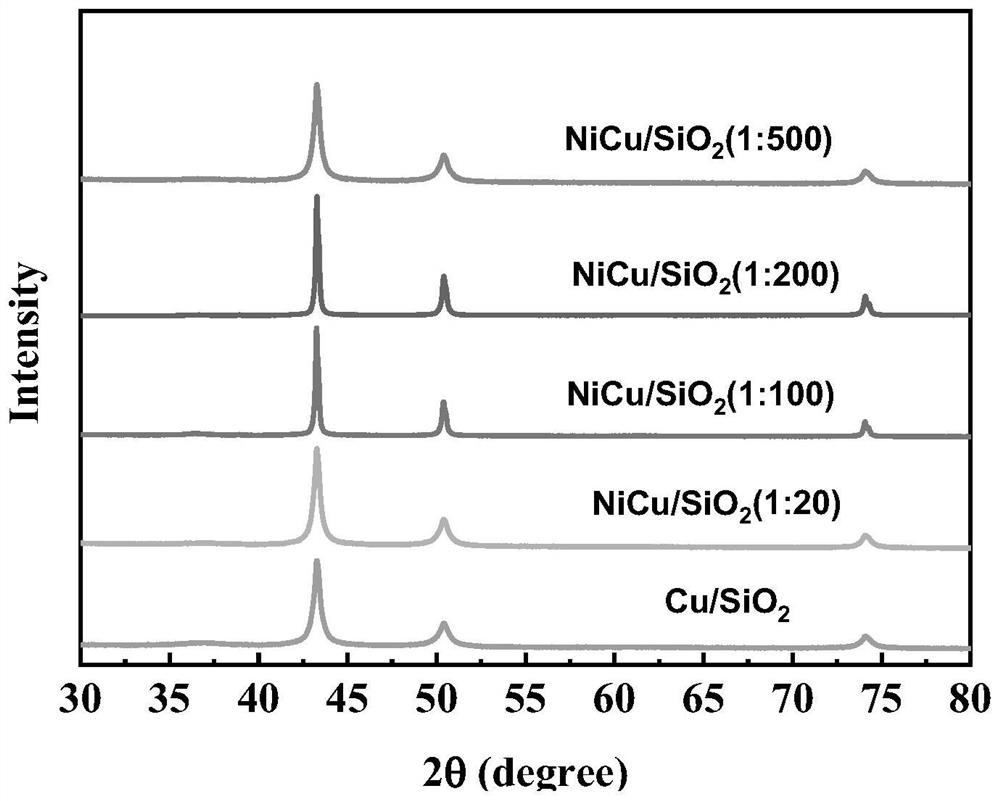

[0050] Compared with Example 1, the difference is: Nickel nitrate and Cu / SiO 2 The mass ratio is 1: 20, and other steps are with embodiment 1, and the catalyst that finally obtains is NiCu / SiO 2 (1:20).

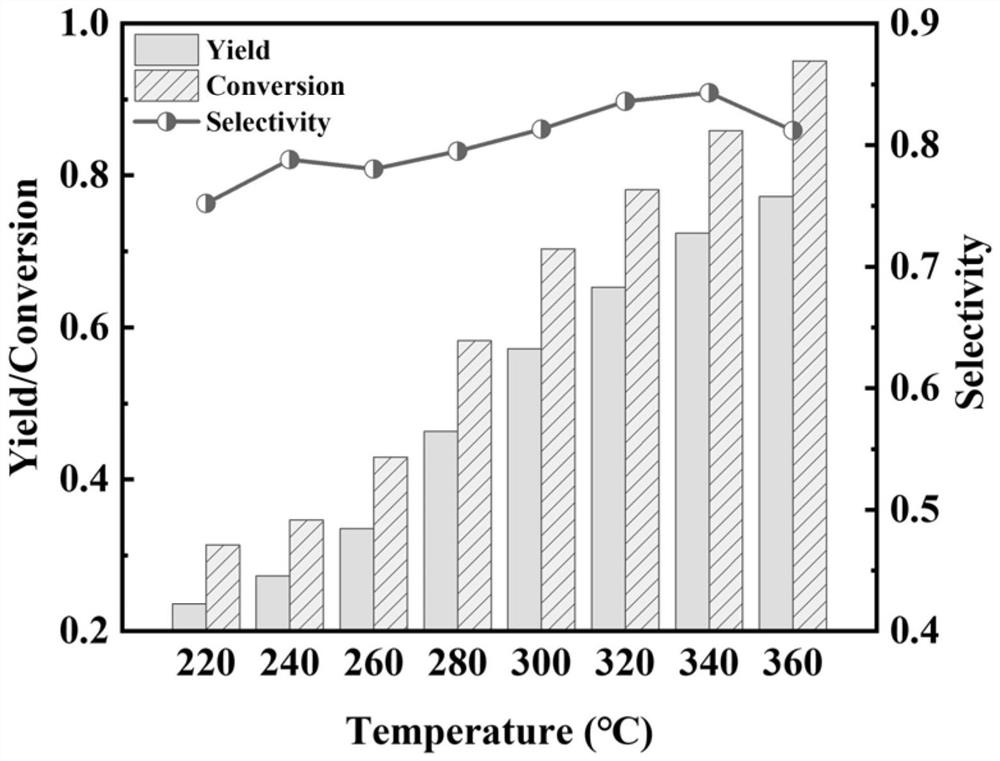

[0051] 0.5g of catalyst was weighed and put into the fixed bed, and benzyl alcohol solution was passed into it under the protection of 10ml / min of argon, and the temperature was raised to 340°C to carry out the reaction, and the reaction pressure was normal pressure, and the reaction selectivity: 78.2%; : 90.4%; reaction yield: 70.7%.

[0052] Under the condition that other conditions remain unchanged, the temperature is raised to 220° C. to carry out the reaction, and the reaction selectivity: 70.4%; the reaction conversion rate: 30.7%; the reaction yield: 21.6%.

[0053] Under the condition that other conditions remain unchanged, the temperature is raised to 240° C. to carry out the reaction, and the reaction selectivity: 76.3%; the reaction conversion rate: 35.1%; the re...

Embodiment 3

[0060] Compared with Example 1, the difference is: the nickel nitrate and Cu / SiO 2 The mass ratio is 1: 100, and other steps are the same as in Example 1, and the catalyst finally obtained is NiCu / SiO 2 (1:100).

[0061] Weigh 0.5g of catalyst and put it into the fixed bed, and pass benzyl alcohol solution under the protection of 10ml / min of argon, heat up to 360 ℃ to carry out the reaction, the reaction selectivity: 83.7%; the reaction conversion rate: 88.4%; the reaction yield Rate: 74.0%.

[0062] Under the condition that other conditions remain unchanged, the temperature is raised to 220° C. to carry out the reaction, and the reaction selectivity: 76.5%; the reaction conversion rate: 32.5%; the reaction yield: 24.9%.

[0063] Under the condition that other conditions remain unchanged, the temperature is raised to 240° C. to carry out the reaction, and the reaction selectivity: 79.4%; the reaction conversion rate: 36.0%; the reaction yield: 28.6%.

[0064] Under the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com