Multifunctional bioprotein-based aerogel material as well as preparation method and application thereof

A biological protein and aerogel technology, applied in the field of materials, can solve the problems of single function, poor mechanical properties of biological protein aerogels, lack of functional properties such as medicinal properties, etc., and achieve high filtration efficiency, excellent biocompatibility and Effects of degradability, high catalytic and dissolution properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

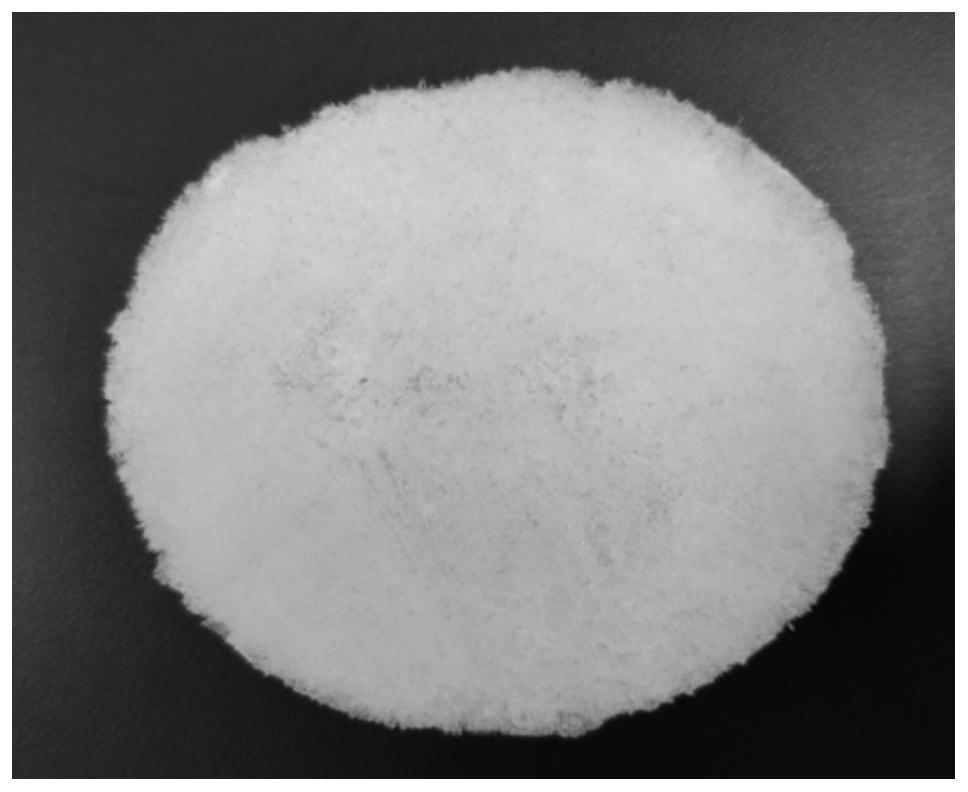

[0040] A preparation method of a multifunctional biological protein-based aerogel material, comprising the following steps:

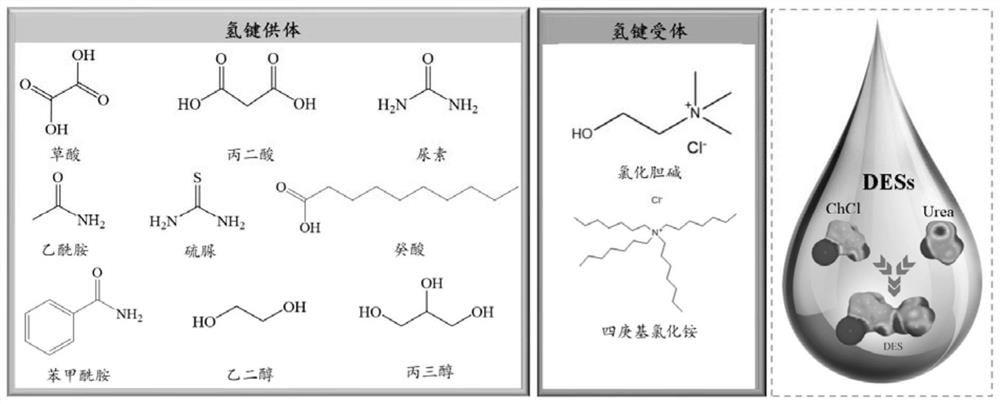

[0041] 1) prepare a deep eutectic solvent, and the raw material composition of the partial preparation solvent is as follows figure 1 shown. In this example, cysteine and lactic acid are used as examples, and the specific method for preparing the deep eutectic solvent is as follows: measure 5g cysteine and 40ml of lactic acid aqueous solution with a mass concentration of 80% and add them into a conical flask; put them into a magnetic stirrer , dissolve at 110°C for two hours, and set aside for use; immerse the washed and dried down in a synthetic deep eutectic solvent, control the bath ratio to 40:1, dissolve and peel down the down fibers at 100°C, and control the peeling time at 4 Within hours, a translucent viscous red liquid was formed.

[0042] 2) At room temperature of 25°C, dialyze the solution obtained in step 1) with a dialysis bag of 8KD-...

Embodiment 2

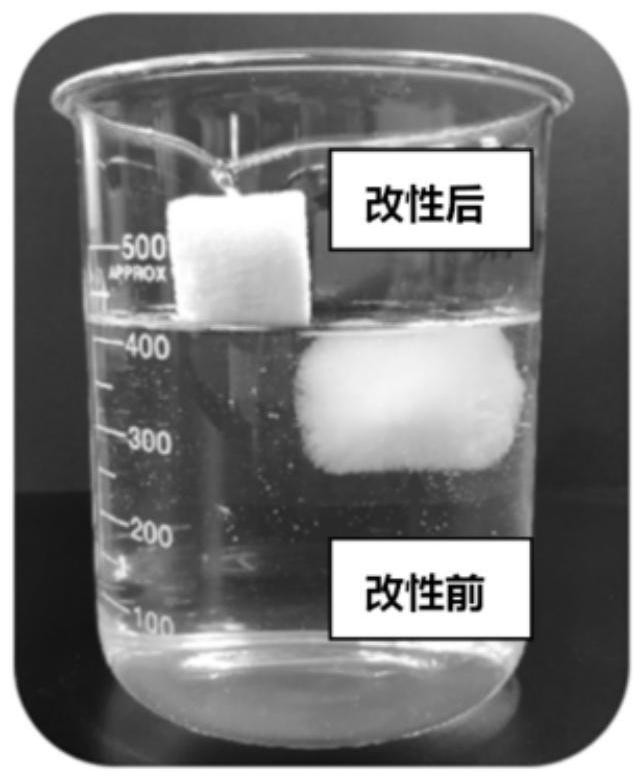

[0046]The application of a multifunctional biological protein-based aerogel material, which is used to prepare a hydrophobic material. The hydrophobic multifunctional aerogel material is prepared by a vapor deposition method. The specific method is as follows: taking 3 ml of methyltrimethoxysilane and 1.5 ml of The water was put into two open vials, and the two vials were placed in a closed container together with the aerogel prepared in Example 1 (cylindrical, with a height of 1.2 cm and a bottom diameter of 5 cm). The silanized aerogel material was placed in a vacuum oven at 60°C for 12 hours to remove excess methyltrimethoxysilane and complete the hydrophobic modification.

[0047] Taking the same size aerogel material without hydrophobic modification, as the material before modification and the above modified material, the following tests were carried out:

[0048] The same method was used to drip water on the surface of the aerogel before and after modification. Before th...

Embodiment 3

[0050] An application of a multifunctional biological protein-based aerogel material for drug loading, the drug-loaded aerogel material is prepared by a eutectic method, and the specific method is as follows:

[0051] The commercially available Coptis chinensis extract was dissolved in the feather protein fibril dispersion after dialysis in Example 1 step 2), and the mass ratio of the Coptis chinensis extract and the dialysis post-dialysis feather protein fibril dispersion was set to 1:20, and the prepared total was 1:20. The melt system was ultrasonically treated in a Scientz-CHF-5B ultrasonic bath at a frequency of 40 kHz under the condition of 400W for 2 hours to increase the degree of fusion between the two. During the ultrasonic treatment, an ice bath environment was maintained to avoid the oxidative decomposition of berberine. After that, the dispersion liquid was poured into a polytetrafluoroethylene mold, and pre-frozen at -60 °C for 15 hours, and then freeze-dried in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com