Production method of low-TOC ultra-high-purity hydrogen peroxide

A production method, technology for hydrogen peroxide, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, climate sustainability, etc., can solve the problem of increasing hydrogen peroxide storage And transportation cost, low concentration of hydrogen peroxide and other problems, to reduce the difficulty of purification, reduce processing steps, and ensure the effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

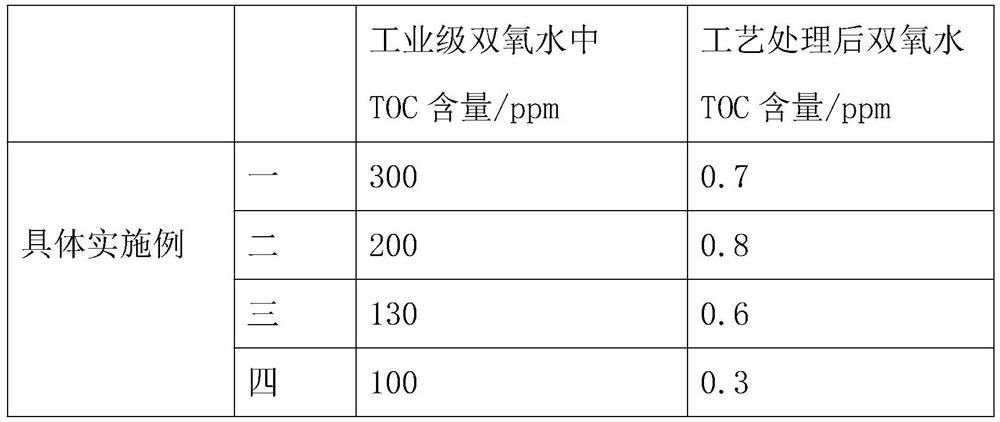

Examples

Embodiment 1

[0029] A kind of production method of low TOC ultra-high purity hydrogen peroxide, comprises the steps:

[0030] S1. Preparation of raw materials: prepare 600ml of sodium dihydrogen phosphate, 400ml of sodium hydroxide, 90ml of enhanced distilling agent, 20g of activated carbon and 50g of dewatering agent;

[0031] S2, the mixing reaction of raw materials: the sodium hydroxide solution in the step (1) is added to a suitable reaction vessel, then sodium dihydrogen phosphate is gradually added to the reaction vessel, and the mixed solution in the reaction vessel is stirred, stirring Manual stirring is adopted, and the pH of the mixed solution in the reactor is measured at the same time, and the pH is measured by an electronic pH meter, until the pH of the mixed solution is at 8.0, and the hydrogen peroxide mixed solution is prepared;

[0032] S3, preliminary purification of hydrogen peroxide: the hydrogen peroxide mixed solution in step (2) is poured into the cooling pool for co...

Embodiment 2

[0039] A kind of production method of low TOC ultra-high purity hydrogen peroxide, comprises the steps:

[0040] S1. Preparation of raw materials: prepare 700ml of sodium dihydrogen phosphate, 500ml of sodium hydroxide, 120ml of enhanced distilling agent, 30g of activated carbon and 70g of dewatering agent;

[0041] S2, the mixing reaction of raw materials: the sodium hydroxide solution in the step (1) is added to a suitable reaction vessel, then sodium dihydrogen phosphate is gradually added to the reaction vessel, and the mixed solution in the reaction vessel is stirred, stirring Manual stirring was adopted, and the pH of the mixed solution in the reactor was measured at the same time, and the pH was measured by an electronic pH meter, until the pH of the mixed solution was at 8.8, and the hydrogen peroxide mixed solution was prepared;

[0042] S3, preliminary purification of hydrogen peroxide: the hydrogen peroxide mixed solution in step (2) is poured into the cooling pool ...

Embodiment 3

[0049] A kind of production method of low TOC ultra-high purity hydrogen peroxide, comprises the steps:

[0050] S1. Preparation of raw materials: prepare 700ml of sodium dihydrogen phosphate, 500ml of sodium hydroxide, 120ml of enhanced distilling agent, 30g of activated carbon and 70g of dewatering agent;

[0051] S2, the mixing reaction of raw materials: the sodium hydroxide solution in the step (1) is added to a suitable reaction vessel, then sodium dihydrogen phosphate is gradually added to the reaction vessel, and the mixed solution in the reaction vessel is stirred, stirring Manual stirring was adopted, and the pH of the mixed solution in the reactor was measured at the same time, and the pH was measured by an electronic pH meter, until the pH of the mixed solution was at 8.8, and the hydrogen peroxide mixed solution was prepared;

[0052] S3, preliminary purification of hydrogen peroxide: the hydrogen peroxide mixed solution in step (2) is poured into the cooling pool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com