Manufacturing method of quantum dot laser

A production method and quantum dot technology, applied in the direction of lasers, phonon exciters, semiconductor lasers, etc., can solve problems such as the inability to prepare high-quality p-GaN layers, and achieve low cost, fast growth rate, and high preparation quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

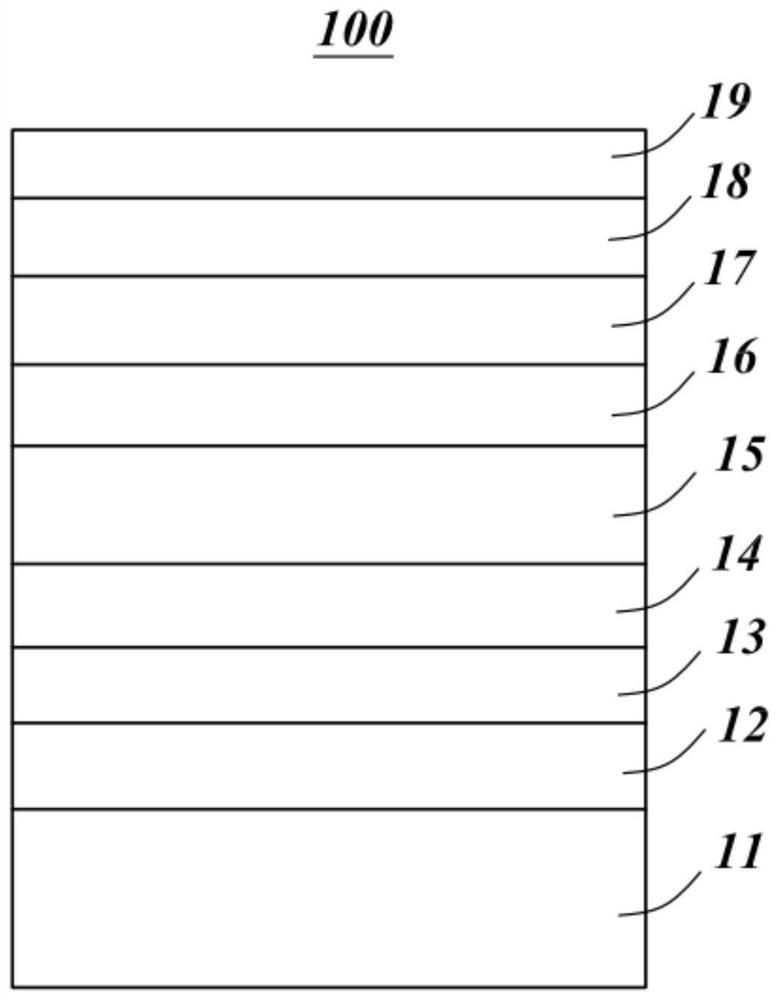

[0041] ginseng figure 1 As shown, the quantum dot laser 100 includes a substrate 11, a buffer layer 12, an n-type confinement layer 13, an n-type waveguide layer 14, a quantum dot active region 15, a p-type waveguide layer 16, an electron confinement layer 17, and a p-type confinement layer. 18 and p-type contact layer 19.

[0042] The substrate 11 is a sapphire substrate or a Si substrate; the buffer layer 12 is doped n-GaN with a thickness of 5 μm, using Si as a dopant, and the doping concentration is greater than or equal to 2×10 18 cm -2 ; The n-type confinement layer 13 is a plurality of periods of Al 0.15 GaN 0.85 / GaN, the overall thickness is 1000nm, the number of cycles is 200, Si is used as a dopant, and the doping concentration is greater than or equal to 2×10 18 cm -2 ; n-type waveguide layer 14 is In 0.05 Ga 0.95 N, the thickness is 100nm, Si is used as the dopant, and the doping concentration is greater than or equal to 1×10 18 cm -2 ; The quantum dot ac...

Embodiment 2

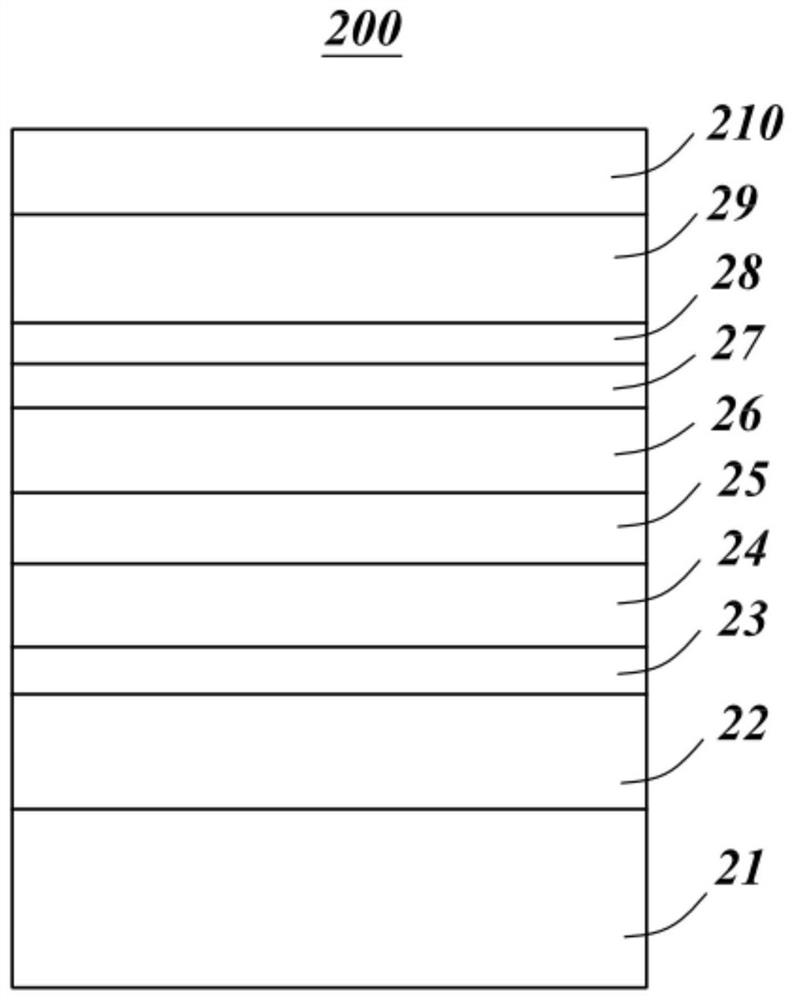

[0048] ginseng figure 2 As shown, quantum dot laser 200 includes substrate 21, n-type confinement layer 22, n-type spacer layer 23, n-type waveguide layer 24, quantum dot active region 25, p-type waveguide layer 26, p-type spacer layer 27, electrons Confinement layer 28 , p-type confinement layer 29 and p-type contact layer 210 .

[0049] The substrate 21 is an n-type GaN self-supporting substrate; the n-type confinement layer 22 is a plurality of cycles of Al 0.15 GaN 0.85 / GaN, Al 0.15 GaN 0.85 The thickness of the layer is 2.5nm, the thickness of the GaN layer is 2.5nm, and the number of cycles is 200. Si is used as a dopant, and the doping concentration is greater than or equal to 2×10 18 cm -2 ; The thickness of the n-type GaN spacer layer 23 is 10 nm. Si is used as a dopant, and the doping concentration is greater than or equal to 1×10 18 cm -2 ; n-type waveguide layer 24 is In 0.05 Ga 0.95 N, the thickness is 120nm, Si is used as the dopant, and the doping co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com