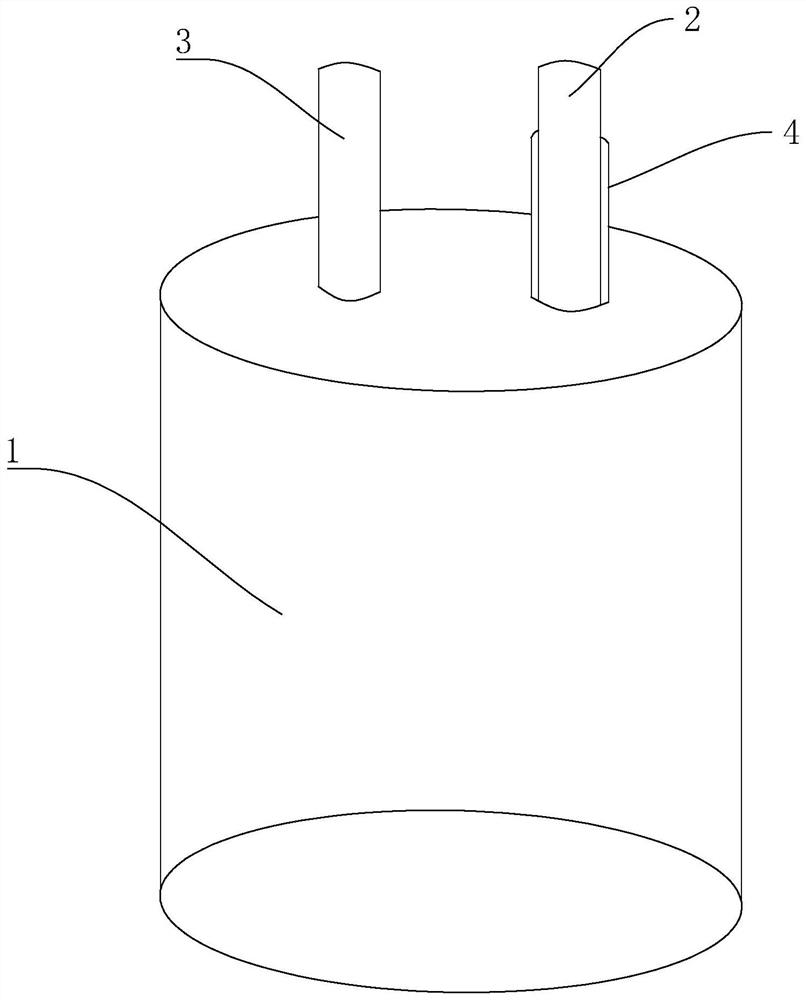

Soldering lug type aluminum electrolytic capacitor electrolyte and preparation method thereof

An aluminum electrolytic capacitor and electrolyte technology, applied in the field of electrolyte, can solve problems such as poor effect, and achieve the effects of excellent waterproofness, improved waterproofness, and good waterproofness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0057] The preparation method of mixed ester is:

[0058] Put 10kg hypophosphorous acid and 10kg polymethacrylic acid into the stirred tank, stir at a temperature of 60 ° C and a rotating speed of 20 rad / min, after stirring, add 2 kg of formic acid and 2 kg of glacial acetic acid and continue at 60 ° C, Stirring is carried out under the condition that the rotating speed is 20rad / min to obtain a viscous liquid;

[0059] 5 parts of 3-methyl-1,5-pentanediol was added to the viscous solution, mixed and stirred at a rotational speed of 20 rad / min, and dried at a temperature of 50° C. to obtain a mixed ester.

preparation example 2

[0061] Put 20kg of hypophosphorous acid and 20kg of polymethacrylic acid into the stirring tank, stir at a temperature of 60 ° C and a rotating speed of 20 rad / min, after the stirring is completed, add 8 kg of formic acid and 8 kg of glacial acetic acid and continue at 60 ° C, Stirring is carried out under the condition that the rotating speed is 20rad / min to obtain a viscous liquid;

[0062] 15 parts of 3-methyl-1,5-pentanediol was added to the viscous solution, mixed and stirred at a rotational speed of 20 rad / min, and dried at a temperature of 50° C. to obtain a mixed ester.

preparation example 3

[0064] Put 13.8kg of hypophosphorous acid and 18.6kg of polymethacrylic acid into the stirred tank, stir at a temperature of 60 ° C and a rotating speed of 20 rad / min, after the stirring is completed, add 8kg of formic acid and 8kg of glacial acetic acid and continue at 60 ℃, stirring under the condition of rotating speed of 20rad / min to obtain a viscous liquid;

[0065] 6 parts of 3-methyl-1,5-pentanediol were added to the viscous liquid, mixed and stirred at a rotational speed of 20 rad / min, and dried at a temperature of 50° C. to obtain a mixed ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com