Preparation method of TiAl/Ti2AlC coating with strong combination and high corrosion resistance

A high corrosion resistance and coating technology, which is applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of low purity of MAX phase and unsatisfactory corrosion resistance, so as to improve corrosion resistance and oxidation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

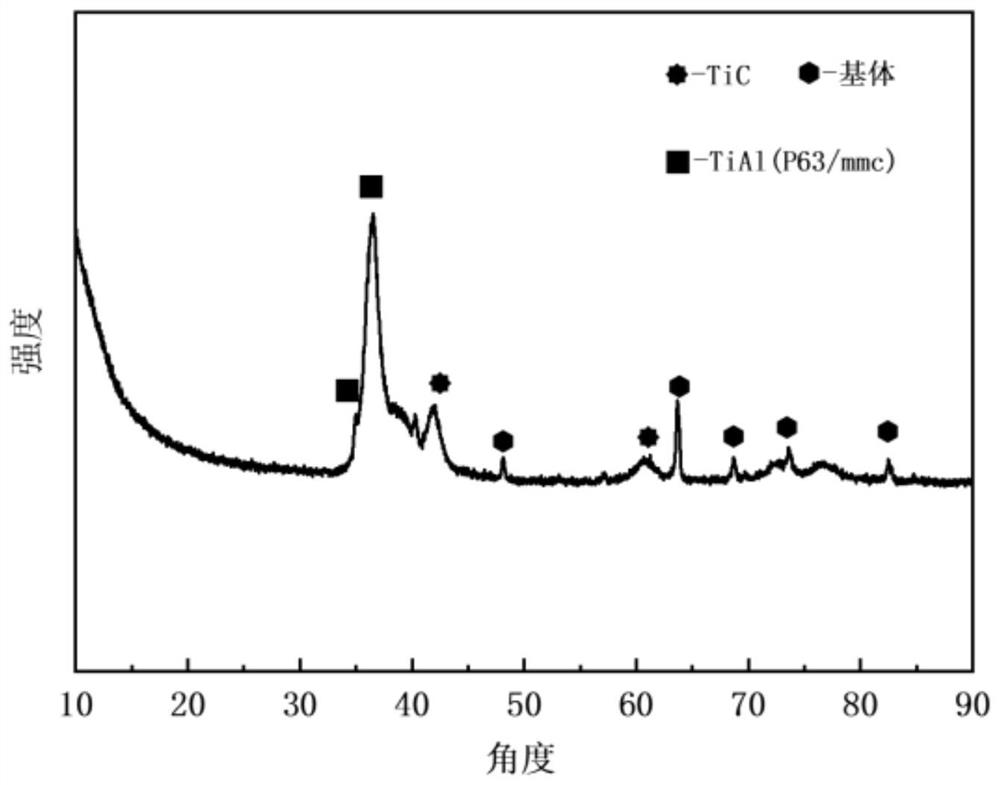

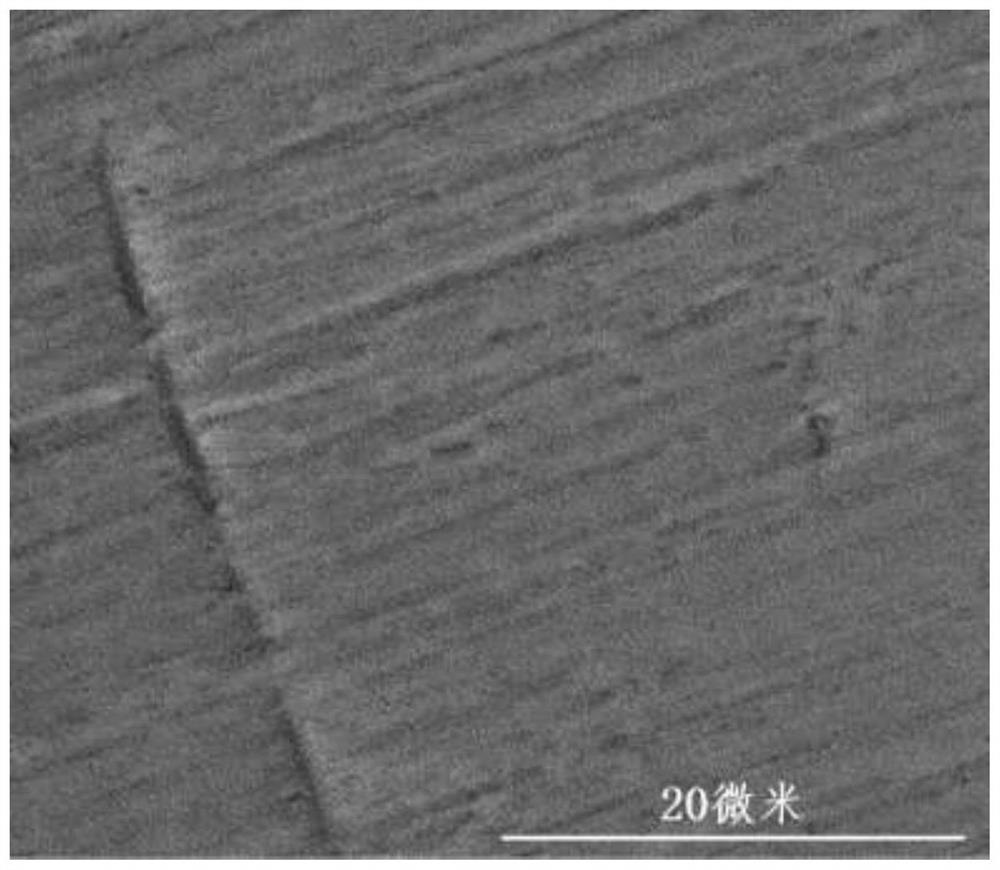

[0048] In this embodiment, the substrate is used as a TC serving a device in a seawater environment 4 The preparation method of the Ti-Al-C MAX phase coating on the surface of the substrate is as follows:

[0049] (1) Wash the substrate with acetone and alcohol in turn to remove grease and soluble impurities on the surface, put it into the cavity, and wait until the pressure in the cavity reaches 10 -3 At Pa, the substrate was heated to 400 °C for 5 min, and the heating was turned off. When the vacuum degree reaches 2.0×10 -3 Below Pa, 50sccm of argon gas was passed into the cavity, the substrate bias was set to -400V, and the sample was cleaned with ionized argon ions for 30min.

[0050] (2) The temperature was heated to 300° C. and maintained, and the TiAl transition layer was deposited by high-power pulsed magnetron sputtering, wherein the cathode target provided Ti and Al sources, and the power of the sputtering target was adjusted to 115W. The argon flow rate was set t...

Embodiment 2

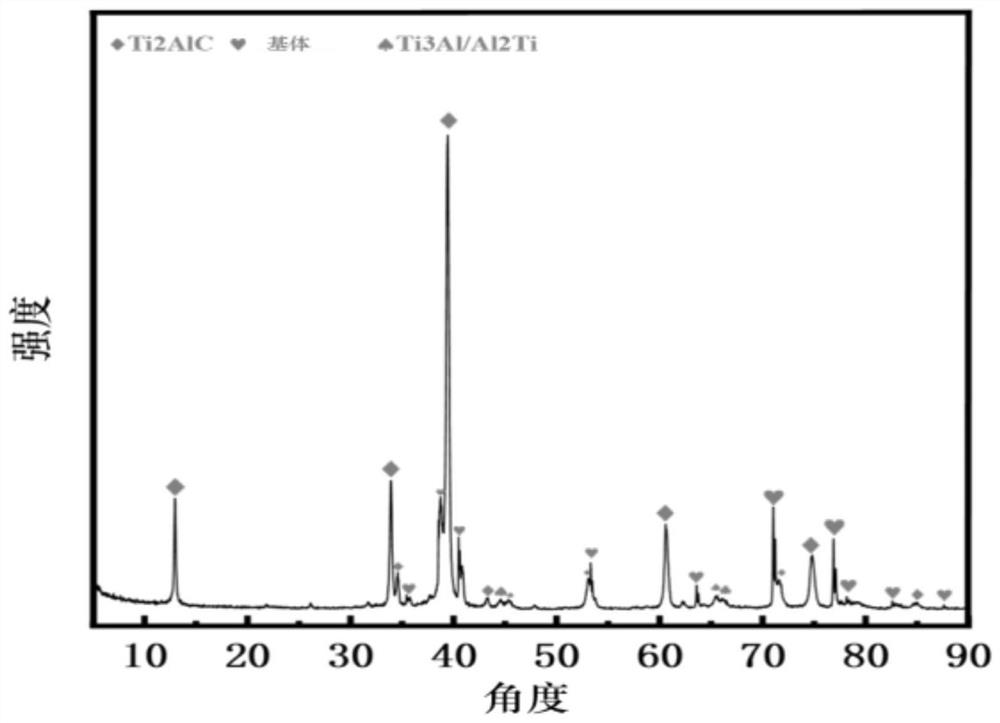

[0059] Different from Example 1, in this comparative example, the bias voltage is -80V. After annealing at 700°C, the phase purity of the sample reaches 83wt%, and only a small amount of TiAl exists. The corrosion current density is 2×10 -10 A / cm 2 , the binding force reaches 70N, among which, Figure 4 XRD pattern of the MAX phase coating prepared in Example 2.

Embodiment 3

[0061] The difference from Example 1 is that the power of the TiAl target in this comparative example is 115W. After annealing at 700°C, the TiAl 2 The content of AlC MAX phase reaches 88wt%, and there is a trace of TiAl crystallization peak, and the corrosion current density is 4×10 -10 A / cm 2 , the binding force is 73N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com