Composite desulfurization and denitrification agent for flue gas purification of power plant and preparation method of composite desulfurization and denitrification agent

A technology for desulfurization, denitrification and flue gas purification, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve the problems of complex preparation process of desulfurization and denitrification agent, high investment and operation cost, complex preparation process, etc., and achieve cooling time The effect of short, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

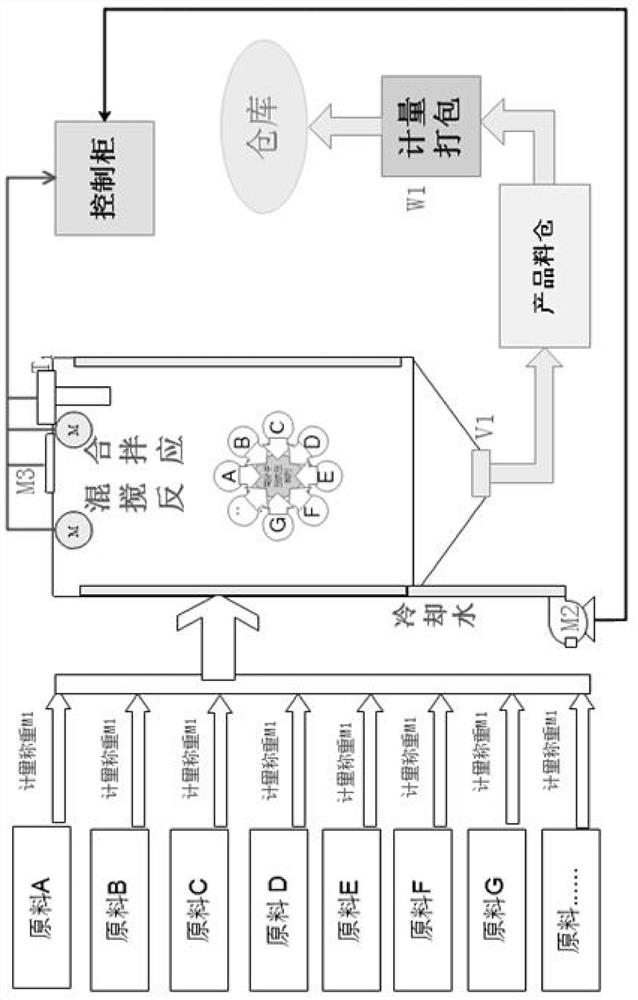

Method used

Image

Examples

Embodiment 1

[0028] Weigh 40 parts by mass of bis-nitrile amine (as a desulfurization and denitration agent), 5 parts of sodium polyvinylidene (as a synergistic polymer), 40 parts of calcium citrate (as an alkaline substance), 5 parts of soda (as a Alkaline substance), 5 parts silica powder (as auxiliary agent), 3 parts aluminum oxide (as auxiliary agent), 2 parts Mn 2 O 3 (as an auxiliary agent), put it into the reactor, run at a linear speed of 8m / s for 10min, and control the temperature at 65-70℃ under normal working conditions. After that, the stirring line speed dropped to 1m / s, and after running for 2min, the discharge valve was opened to discharge the material.

[0029] The performance of the desulfurization and denitration agent was tested in a 2520 stainless steel reactor with an electric heating temperature of 850-1200°C. with NO and SO 2 The gas cylinder is introduced from the bottom of the reactor, using N 2 Diluted as an inert atmosphere for NO and SO 2 Concentration res...

Embodiment 2

[0035]Weigh 50 parts by mass of imine (as desulfurization and denitration), 6 parts of poly-N-vinyl butyl lactam (as synergistic polymer), 35 parts of potassium bicarbonate (as alkaline substance), 5 parts of carbonic acid Magnesium (as an alkaline substance), 4 parts talc (as an aid), 2 parts aluminum oxide (as an aid), 2 parts soda (as an aid), placed in a mixing reactor at line speed Run at 10m / s for 16min, and the temperature is controlled at 60-75℃. After that, the stirring line speed dropped to 1m / s, and after running for 2min, the discharge valve was opened to discharge the material.

[0036] The performance of the desulfurization and denitrification agent was tested in a 2520 stainless steel reactor with an electric heating temperature of 850-1200 °C. with NO and SO 2 The gas cylinder is introduced from the bottom of the reactor, using N 2 Diluted as an inert atmosphere for NO and SO 2 Concentration respectively controls the required concentration range. The comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com