Paste boriding agent as well as preparation method and application thereof

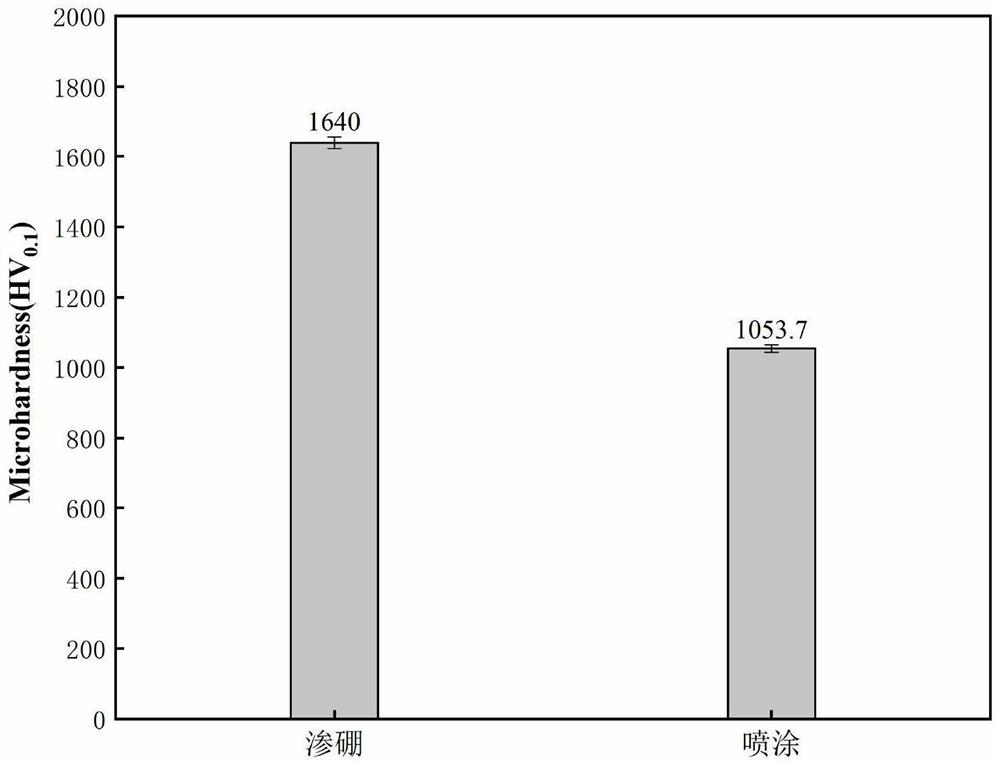

A boronizing agent and paste-like technology, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of easy peeling of boronizing layer and parts failure, and achieve the elimination of softening phenomenon in the transition zone and reduce the cost Low, the effect of microhardness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

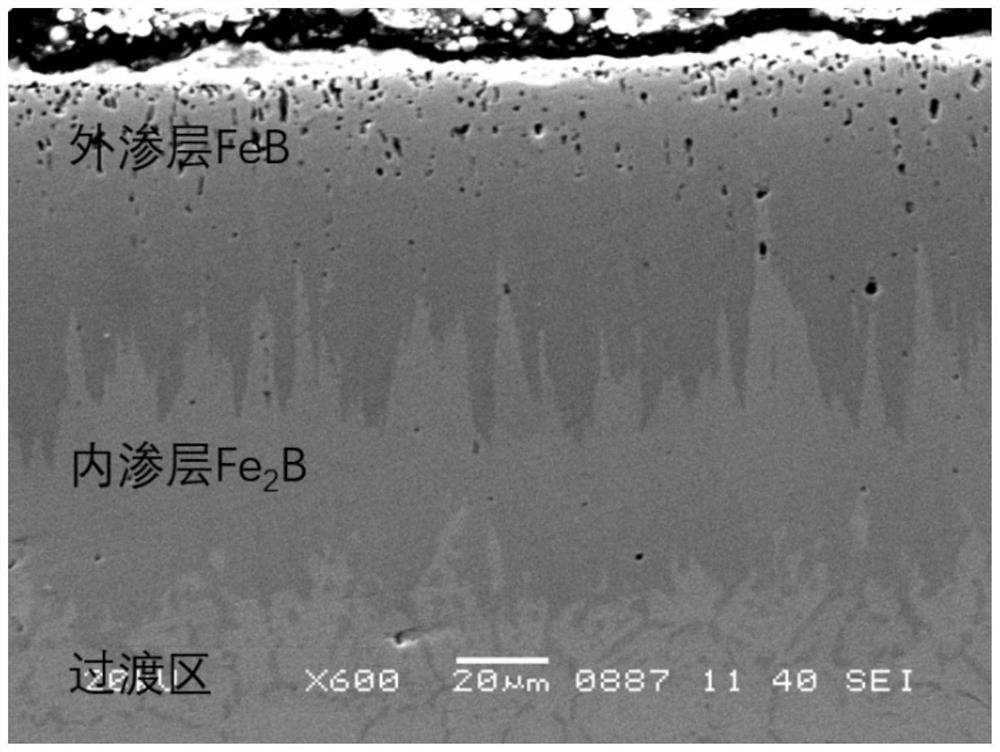

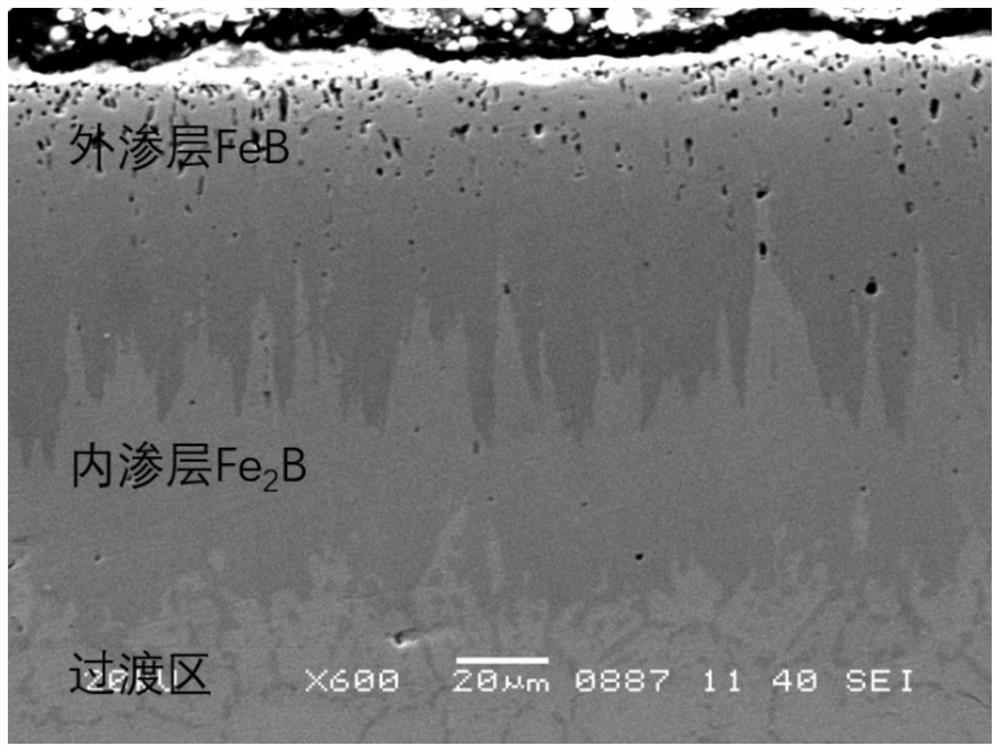

[0029] Put 0.5kg of boron carbide with a particle size of 200 objects, 0.3kg of potassium fluoroborate with a particle size of 230 objects, 0.08kg of ceria with a particle size of 300 objects, and 0.12kg of silicon carbide with a particle size of 200 objects into the ball mill tank, and then put the total weight of 1kg zirconia grinding balls with a diameter of 15mm were placed on a pot mill for mixing treatment. The mixing time was 24h, so that the components in the boronizing agent were mixed evenly; the weight percent was added to the evenly mixed boronizing agent. It is a 5% polyvinyl alcohol aqueous solution to make a paste boronizing agent; 410 stainless steel plates are polished step by step on 80#, 200#, 400#, 600#, 1000# water-resistant sandpaper, and the polished surfaces are all fine When there are small scratches in the same direction, ultrasonically clean with acetone for 5 minutes before use; apply a 5mm thick paste boronizing agent on the surface of the 410 stain...

Embodiment 2

[0032] Put 0.5kg of boron carbide with a particle size of 200 objects, 0.2kg of potassium fluoroborate with a particle size of 230 objects, 0.06kg of ceria with a particle size of 400 objects, and 0.24kg of silicon carbide with a particle size of 400 objects into the ball mill tank, and then put the total weight of 1kg zirconia grinding balls with a diameter of 15mm were placed on a pot mill for mixing treatment. The mixing time was 24h, so that the components in the boronizing agent were mixed evenly; the weight percent was added to the evenly mixed boronizing agent. It is a 10% polyvinyl alcohol aqueous solution to make a paste boronizing agent; the Q235A carbon structural steel plate is polished step by step on 80#, 200#, 400#, 600#, 1000# water-resistant sandpaper. When the scratches are small and in the same direction, use acetone to ultrasonically clean for 5 minutes; apply a 7mm thick paste boronizing agent on the surface of the Q235A carbon structural steel plate, put i...

Embodiment 3

[0035]Put 0.3kg of boron carbide with a particle size of 300 objects, 0.2kg of potassium fluoroborate with a particle size of 300 objects, 0.1kg of ceria with a particle size of 400 objects, and 0.4kg of silicon carbide with a particle size of 200 objects into the ball mill tank, and then put the total weight of 1kg of zirconia grinding balls with a diameter of 15mm were placed on a pot mill for mixing treatment. The mixing time was 24h, so that the components in the boronizing agent were mixed evenly; the weight percent was added to the evenly mixed boronizing agent. It is an 8% polyvinyl alcohol aqueous solution to make a paste boronizing agent; the 9SiCr low alloy tool steel plate is polished step by step on 80#, 200#, 400#, 600#, 1000# water-resistant sandpaper. For small scratches with the same direction, use acetone to ultrasonically clean for 5 minutes; apply a 7mm thick paste boronizing agent on the surface of the 9SiCr low alloy tool steel plate, put it in a heat treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com