Method for recovering metal elements from molybdenite

A metal element, molybdenite technology, applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems affecting molybdenum oxidation, wrapping, and cumbersome recycling processes, and achieve the effect of avoiding the discharge of ammonia nitrogen wastewater and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

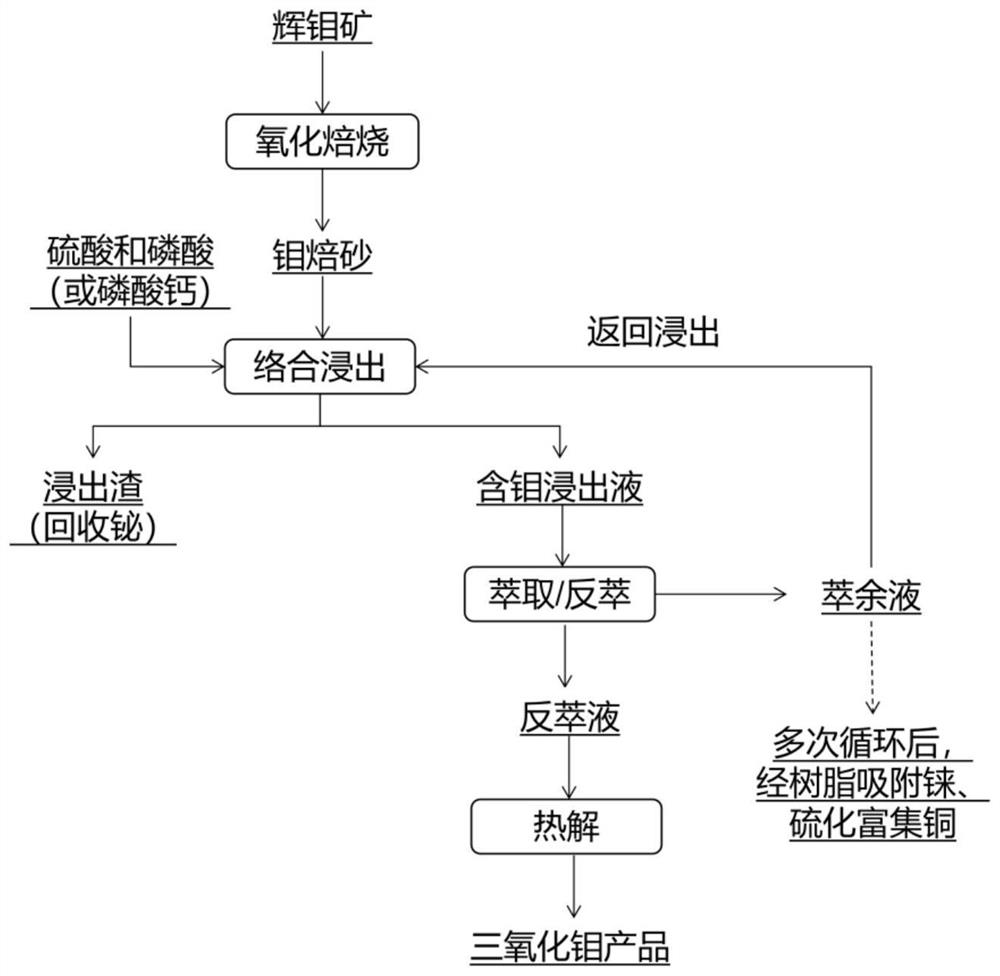

Image

Examples

Embodiment 1

[0080] A specific embodiment of the present invention discloses a method for recovering metal elements and copper from molybdenite.

[0081] The main components of molybdenite raw materials are calculated in mass percentage: molybdenum 46.1%, copper 1.2%, bismuth 2.42%.

[0082] Step 1. Oxidative roasting of molybdenite to obtain molybdenum calcine.

[0083] Step 2. Take phosphoric acid as leaching aid, the sulfuric acid of 100g / L is leaching agent, the consumption of leaching aid is 0.8 times of molybdenite quality, and the liquid-solid ratio of leaching is 13L / kg, and the temperature is under the condition of 100 ℃ , leaching for 5 hours.

[0084] Step 3. After the leaching is completed, cool to room temperature and filter to obtain a filter residue containing 15.1% of bismuth and a filtrate containing molybdenum and copper.

[0085] Among them, the leaching rate of molybdenum is as high as 98.1%, and the leaching rate of copper is as high as 95.2%.

[0086] Step 4. For t...

Embodiment 2

[0092] A specific embodiment of the present invention discloses a method for recovering metal elements and copper from molybdenite.

[0093] The main components of molybdenite raw materials are calculated in mass percentage: molybdenum 50.2%, copper 1.2%, bismuth 2.42%.

[0094] Step 1. Oxidative roasting of molybdenite to obtain molybdenum calcine.

[0095] Step 2. Take calcium phosphate as leaching aid, the sulfuric acid of 50g / L is leaching agent, the consumption of leaching aid is 0.5 times of molybdenite quality, and the liquid-solid ratio of leaching is 8L / kg, and the temperature is the condition of 90 ℃ leaching for 3 hours.

[0096] Step 3. After the leaching is completed, cool to room temperature and filter to obtain a filter residue containing 16% bismuth and a filtrate containing molybdenum and copper.

[0097] Among them, the leaching rate of molybdenum is as high as 98.5%, and the leaching rate of copper is as high as 95%.

[0098] Step 4. For the filtrate cont...

Embodiment 3

[0104] A specific embodiment of the present invention discloses a method for recovering metal elements and copper from molybdenite.

[0105] The main components of molybdenite raw materials are calculated in mass percentage: molybdenum 48.2%, copper 1.2%, bismuth 2.42%.

[0106] Step 1. Oxidative roasting of molybdenite to obtain molybdenum calcine.

[0107] Step 2. Take phosphoric acid as leaching aid, the sulfuric acid of 200g / L is leaching agent, the consumption of leaching aid is 1.2 times of molybdenite quality, and the liquid-solid ratio of leaching is 10L / kg, and the temperature is under the condition of 80 ℃ , leaching for 2 hours.

[0108] Step 3. After the leaching is completed, cool to room temperature and filter to obtain a filter residue containing 16% bismuth and a filtrate containing molybdenum and copper.

[0109] Among them, the leaching rate of molybdenum is as high as 97.5%, and the leaching rate of copper is as high as 95%.

[0110] Step 4. For the filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com