Method for washing residual quinoline phosphomolybdate precipitate in glass sand core crucible

A technology of quinoline phosphomolybdic acid and glass sand core, which is applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high cost, low efficiency, and large amount of medicament usage, and achieve Improves dissolution and separation speed, improves washing efficiency, and shortens drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

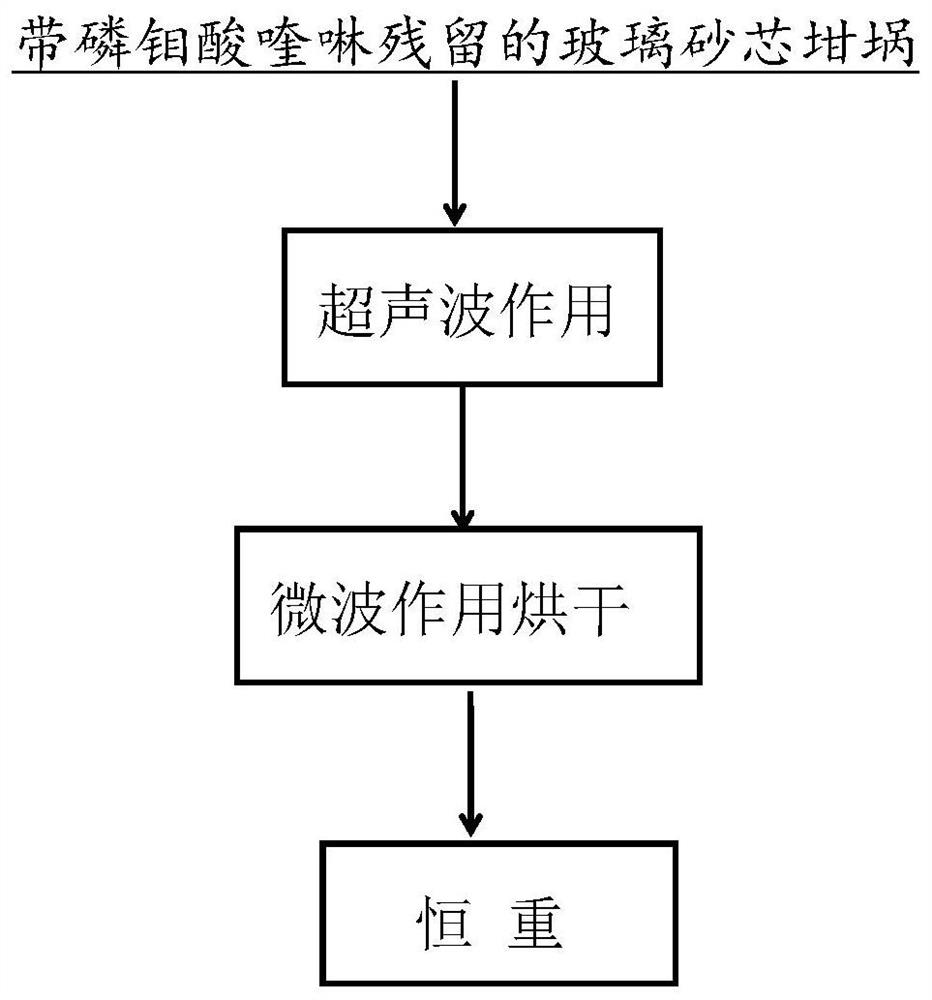

Method used

Image

Examples

Embodiment 1

[0017] The sodium hydroxide solution with a mass concentration of 1% is compounded with ammonia water to form a 1:1 soaking solution for later use. Put the soaking liquid into a plastic container with a lid, and the soaking liquid accounts for 1 / 2 to 2 / 3 of the volume of the container.

[0018] The Analysis and Testing Department of the R&D Center of a Phosphate Group in Yunnan Province completed a batch of 4# glass crucibles for the gravimetric method of quinoline phosphomolybdate (for the content of phosphorus pentoxide in phosphate rock). Wear rubber gloves), pat the bottom lightly, pat out the quinoline phosphomolybdate filter cake and discard, and rinse the glass sand core crucible with the residual quinoline phosphomolybdate precipitation with tap water (mainly rinse the side with the residual precipitation), Put the glass crucible into the soaking solution, cover it, and apply ultrasonic waves for 15 minutes. Take out the ultrasonically cleaned crucible and rinse it wi...

Embodiment 2

[0024] The sodium hydroxide solution with a mass concentration of 1% is compounded with ammonia water to form a 1:1 soaking solution for later use. Put the soaking liquid into a plastic container with a lid, and the soaking liquid accounts for 1 / 2 to 2 / 3 of the volume of the container.

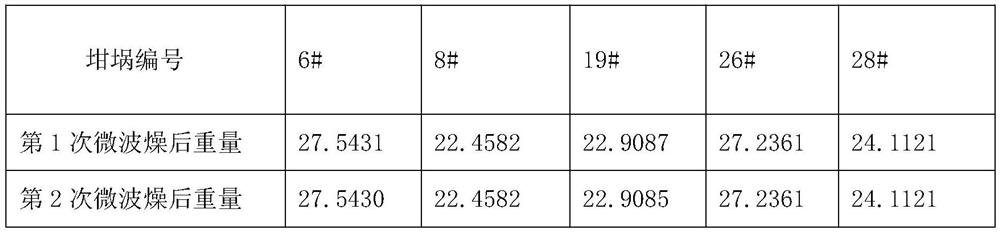

[0025] A batch of 4# glass crucibles for the gravimetric method of quinoline phosphomolybdate (the content of phosphorus pentoxide in the phosphate fertilizer) were prepared in a concentrator in Jinning, Yunnan. Rinse the glass sand core crucible with the residual quinoline phosphomolybdate precipitation with tap water, put the crucible into the soaking solution, cover the lid, apply ultrasonic waves for 20 minutes, take out the crucible and rinse with tap water, Rinse with distilled water for 3 times, put it into a commercial microwave oven, microwave it on medium heat (500w power) for 5 minutes, take it out and place it in a desiccator to cool, weigh, and then microwave it for 1 time to keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com