Chip, method for preparing chip and application of chip

A chip and molecule technology, applied in the field of biochemistry, can solve the problem that the chip needs to be improved, and achieve the effect of avoiding the reduction of synthesis efficiency, reducing the error rate and improving the synthesis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

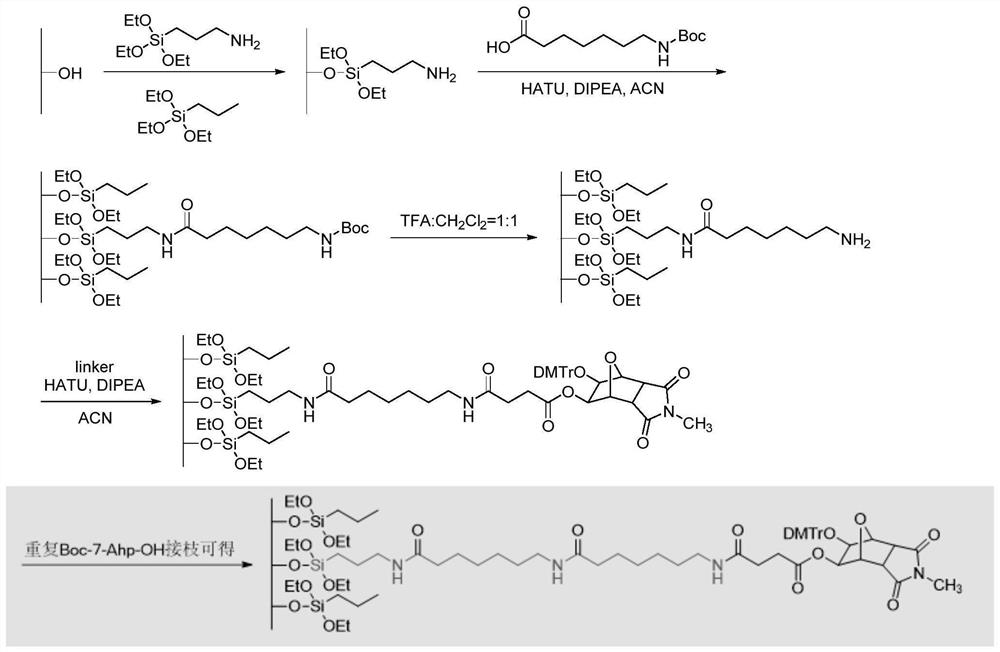

[0087] Example 1: Chip modification with Boc-7-aminoheptanoic acid as spacer molecule

[0088] The process of chip modification such as figure 2 shown, the specific steps are as follows:

[0089] 1. Put the QR code bare chip (2*2*0.45mm) in a 50mL centrifuge tube, add 25mL deionized water, cover with a sealing film, ultrasonically shake for 10min, use deionized water for three times, and acetone for three times , and then placed in an oven at 75 °C for 10 min.

[0090] 2. Prepare 10 mL of 1% silanization reagent (APTES:PTES=1:1), put in 200 cleaned QR code chips, sonicate for 45 min in an ultrasonic machine, wash with acetone for 5 times, dry and place at 75°C Oven dry for 10 min.

[0091] 3. Take 82mg Boc-7-aminoheptanoic acid, 120mg 2-(7-azabenzotriazole)-N,N,N',N'-tetramethylurea hexafluorophosphate (HATU) in 15mL In a centrifuge tube, add 300 μL N,N-diisopropylethylamine (DIPEA) and 15 mL acetonitrile, shake well, put in 200 silanized QR code chips, and sonicate for 4...

Embodiment 2

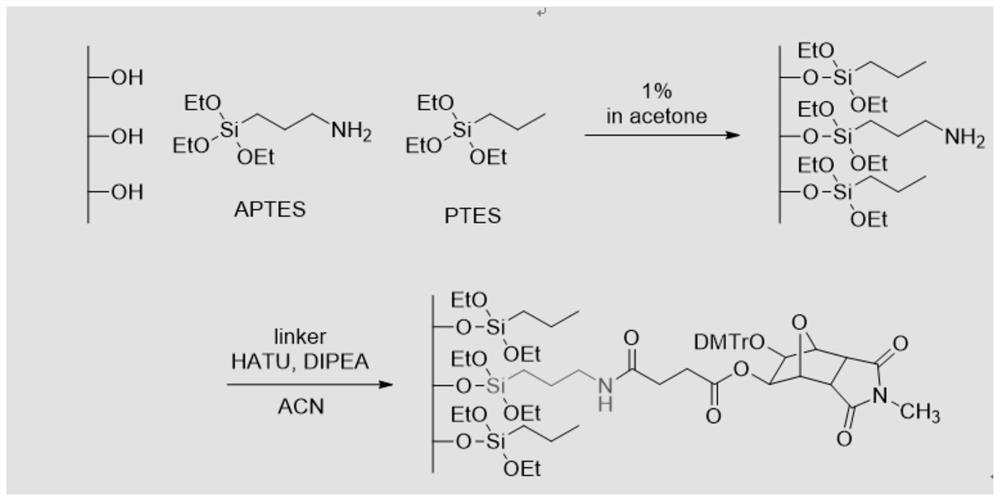

[0098] Example 2: Chip modification without spacer molecules

[0099] The process of chip modification such as image 3 shown, the specific steps are as follows:

[0100] 1. Place the QR code bare chip (2*2*0.45mm) in a 50mL centrifuge tube, add 50mL deionized water, cover with sealing film, ultrasonically shake for 15min, use deionized water for three times, and acetone for three times , and then placed in an oven at 75 °C for 10 min.

[0101] 2. Take 200 mL of acetone, 1000 μL of APTES, and 1000 μL of PTES, add them to the fresh-keeping box in sequence, divide them into two boxes, and mix each box to make 100 ml of 1% silanization reagent. Transfer the dried 5000 chips to crisper boxes, 2500 chips per box. Add 100 mL of silanization reagent, cover tightly, and sonicate for 45 min in a sonicator. After the reaction was completed, it was transferred to a 50 mL centrifuge tube, the solution was drained, washed with acetone for 5 times, dried in the air, and then placed in a...

Embodiment 3

[0105] Example 3: Chip modification with succinic anhydride-hexanediamine as spacer molecule

[0106] The process of chip modification such as Figure 4 shown, the specific steps are as follows:

[0107] 1. Put the QR code bare chip (2*2*0.45mm) in a 50mL centrifuge tube, add 25mL deionized water, cover with a sealing film, ultrasonically shake for 10min, use deionized water for three times, and acetone for three times , to dry.

[0108] 2. Prepare 5mL of 1% silanization reagent (APTES:PTES=1:1), put in 150 cleaned QR code chips, sonicate for 45min in an ultrasonic machine, wash with acetone for 5 times, dry and place at 75°C Oven dry for 10 min.

[0109] 3. Dissolve 17 mg of succinic anhydride in 3 mL of DMF, shake well, put in 150 pieces of silanized two-dimensional code chips, and stir for 24 hours with a vertical stirrer. After the reaction was completed, the chips were collected, washed three times with ethanol and acetone respectively, dried in the air, and then plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com