Shape memory type composite aerogel for inhibiting biological fouling as well as preparation method and application of shape memory type composite aerogel

A composite airgel and biofouling technology, which is applied in the field of preparation, shape-memory inhibition of biofouling, and composite aerogels, can solve the problems of not having the ability to inhibit biofouling, and achieve long-term structural stability and good Antibacterial and anti-biofouling properties, good recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present embodiment prepares biomimetic chitosan aerogel (CS aerogel), and the concrete steps are as follows:

[0048] (1) Take 2g of chitosan powder and evenly mix it into 99mL of deionized water and 1mL of acetic acid, and stir overnight to obtain a 2% chitosan solution;

[0049] (2) The chitosan solution is oriented and frozen with liquid nitrogen, and then freeze-dried to obtain the initial chitosan aerogel, with a freezing time of 30 minutes and a freeze-drying time of 48 hours;

[0050] (3) The initial chitosan aerogel was soaked in methanol solution and tert-butanol solution containing sodium hydroxide to wash, then frozen with liquid nitrogen, and then freeze-dried to obtain biomimetic chitosan aerogel.

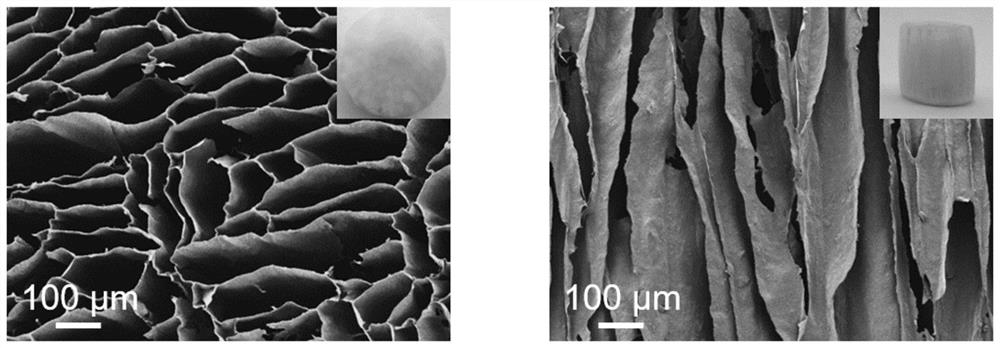

[0051] figure 1 From the scanning electron microscope photos and real photos of the chitosan aerogel in the horizontal and vertical directions in this example, we found that the chitosan aerogel has an oriented pore structure in the longitudinal direction a...

Embodiment 2

[0053] The present embodiment prepares chitosan iron tannate composite aerogel (CST aerogel), and the concrete steps are as follows:

[0054] (1) Preparation of tannic acid-Tris buffer solution: dissolve 0.2 g of tannic acid powder in 100 mL of Tris-HCl buffer solution (pH=8.5), and ultrasonicate for 10 minutes to obtain tannic acid-Tris buffer solution;

[0055] (2) Preparation of tannic acid-aminopropyltriethoxysilane (TA-APTES) solution: dissolve 0.2 g of APTES in 20 mL of absolute ethanol, then slowly add it to the tannic acid buffer, mix well to obtain ( TA-APTES) solution;

[0056] (3) immersing the chitosan aerogel in the TA-APTES solution, performing 6 compression-release cycles in the solution, and then lyophilizing it after washing to obtain a biomimetic chitosan tannin aerogel;

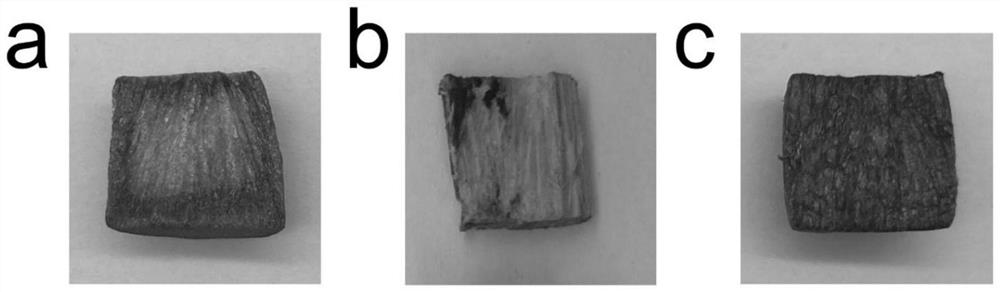

[0057] (4) Immerse the top of the chitosan tannic acid aerogel in 0.2% ferric sulfate solution, and chelate and coordinate tannic acid and iron ions for 0.5 h to make the top dark black, w...

Embodiment 3

[0074]The present embodiment prepares chitosan / iron tannin aerogel (CS-TF aerogel), and the concrete steps are as follows:

[0075] (1) Preparation of tannic acid-Tris buffer solution: dissolve 0.2 g of tannic acid powder in 100 mL of Tris-HCl buffer solution (pH=8.5) to obtain tannic acid-Tris buffer solution;

[0076] (2) Preparation of tannic acid-aminopropyl triethoxysilane (TA-APTES) solution: dissolve 0.2 g of APTES in 20 mL of absolute ethanol, then slowly add it to the tannic acid buffer, mix well to obtain ( TA-APTES) solution;

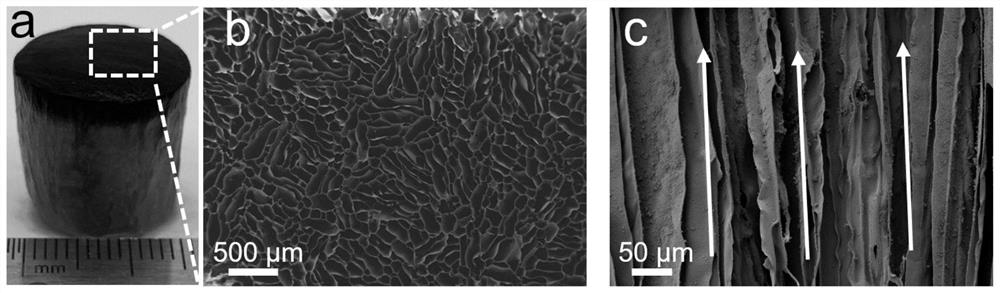

[0077] (3) Immerse the top of the chitosan aerogel in TA-APTES solution, so that the top is adsorbed with tannic acid, the lower layer is kept as chitosan aerogel, and then the upper surface TA layer is immersed in 0.2% ferric sulfate Coordinate in the solution for 0.5h to make the tannic acid on the upper surface and Fe 3+ Chelation coordination results in a photothermal layer. Finally, it was washed with deionized water and freeze-dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com