Kitchen waste pretreatment method

A food waste and pretreatment technology, which is applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems affecting the efficiency of food waste treatment, equipment damage to the production environment, etc., to improve production efficiency, The effect of reducing clogging and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

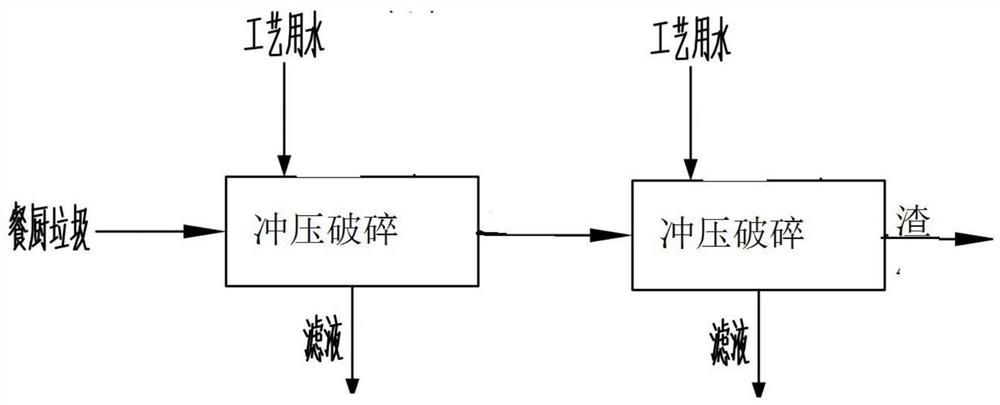

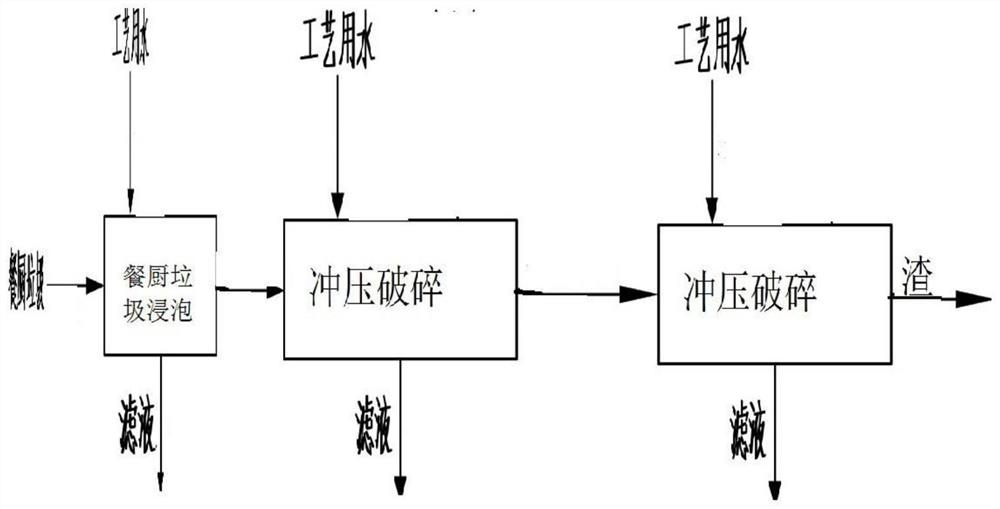

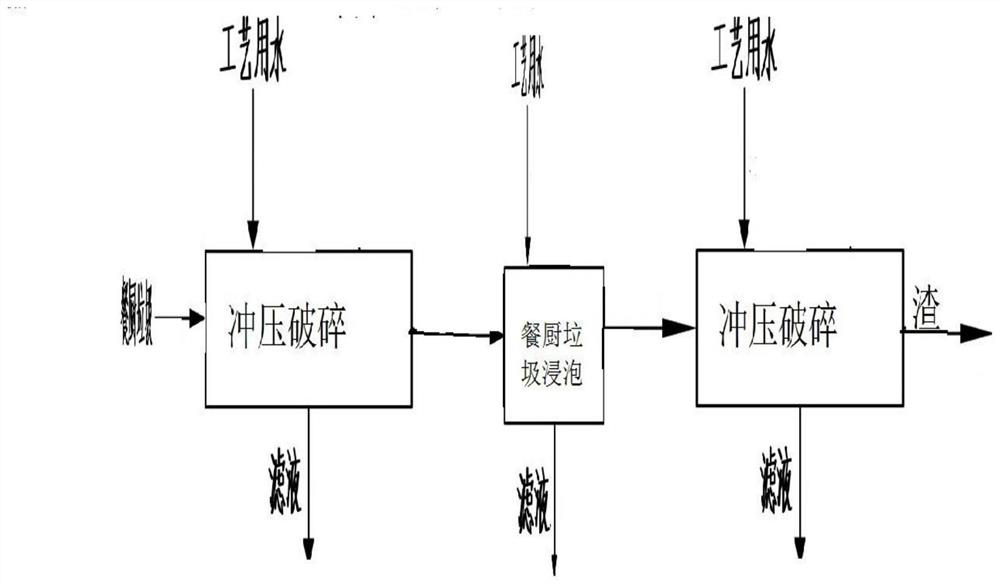

[0028] like figure 1 In the invention, a method for pretreatment of kitchen waste includes the following steps: punching and crushing, punching and sorting;

[0029] The described punching and crushing is washed with water while the kitchen waste is crushed (including before, during and after crushing, the present invention adopts any one or two combinations of the three, or a combination of the three), The rinsed water is collected after being filtered, and the unfiltered kitchen waste enters the punching and sorting step. Preferably, in the punching and crushing step, the water pressure of the rinse water is 0.01-2 standard atmospheres. figure 1 The water pressure of the flushing water used in the process is 0.8-2 standard atmospheric pressure. The size of the water pressure is related to the organic content of the kitchen waste. The organic content is below 92% (excluding 90%). The water pressure is within 1.5-2 standard atmospheric pressure. The interval includes 2 endpoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com