Preparation process of PET (polyethylene terephthalate) material capable of realizing temperature barrier

A technology of preparation process and barrier performance, which is applied in the field of PET material preparation process with temperature barrier performance, can solve the problems of complex fixation, inapplicability to mass product inspection, and detection process that cannot meet the accuracy and speed, so as to optimize the base film Preparation method, good temperature barrier performance, better effect of film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

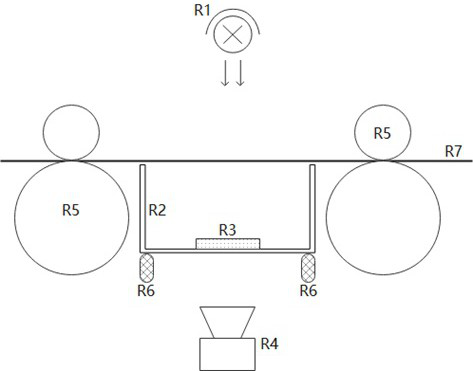

Image

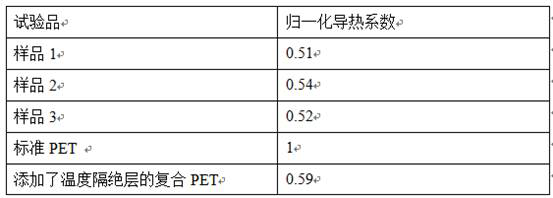

Examples

Embodiment Construction

[0028] (1) Preparation of temperature barrier PET material

[0029] 1. Polymerization of ethylene and norbornene to prepare additive particles. The reactor was flushed with nitrogen, the toluene solution dissolved with norbornene was added to the reactor, ethylene was added, and stirred, and triethylaluminum was added after mixing evenly. 40min. After the reaction is completed, the reaction product is subjected to precipitation filtration, filtered, dried, and then granulated to obtain additive particles. As a preference, the mass ratio of ethylene to norbornene is 85:15-65:35. As a result, the temperature isolation effect after the material is formed can be improved.

[0030] 2. Put the additive particles and recycled PET particles into the heating container for melting and mixing, and add nano-SiO after fully mixing. 2 The particles are mixed and stirred again for 30min, and the stirring speed is 500 rpm. When the additive particles and nano-SiO 2 After the particles ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com