Flue gas denitration utilization device for waste heat boiler of gas turbine

A waste heat boiler and flue gas technology, applied in the field of flue gas denitrification, can solve the problems of high hardware investment cost, high maintenance work and cost, and achieve the effects of saving operating costs, ensuring stable progress, and ensuring stable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

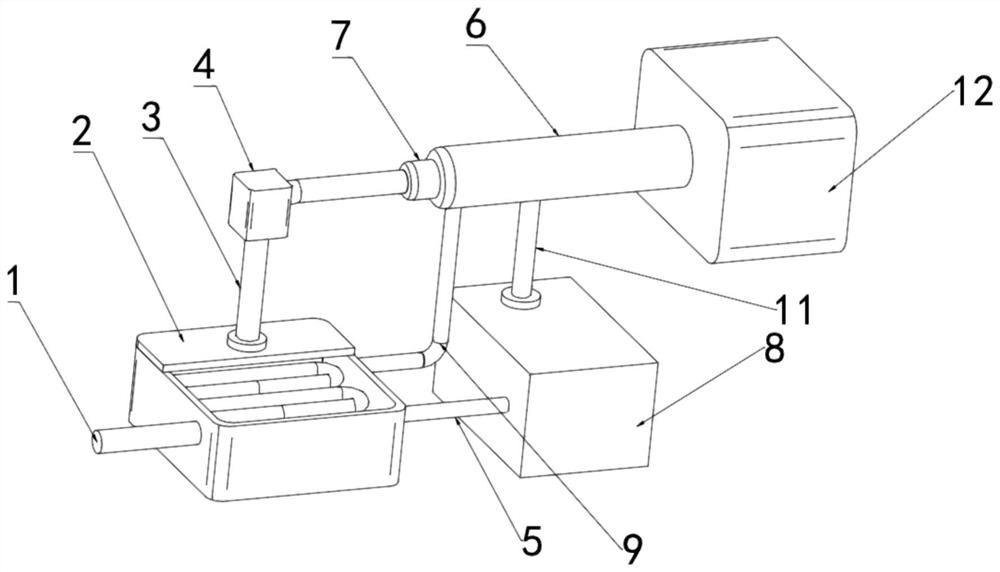

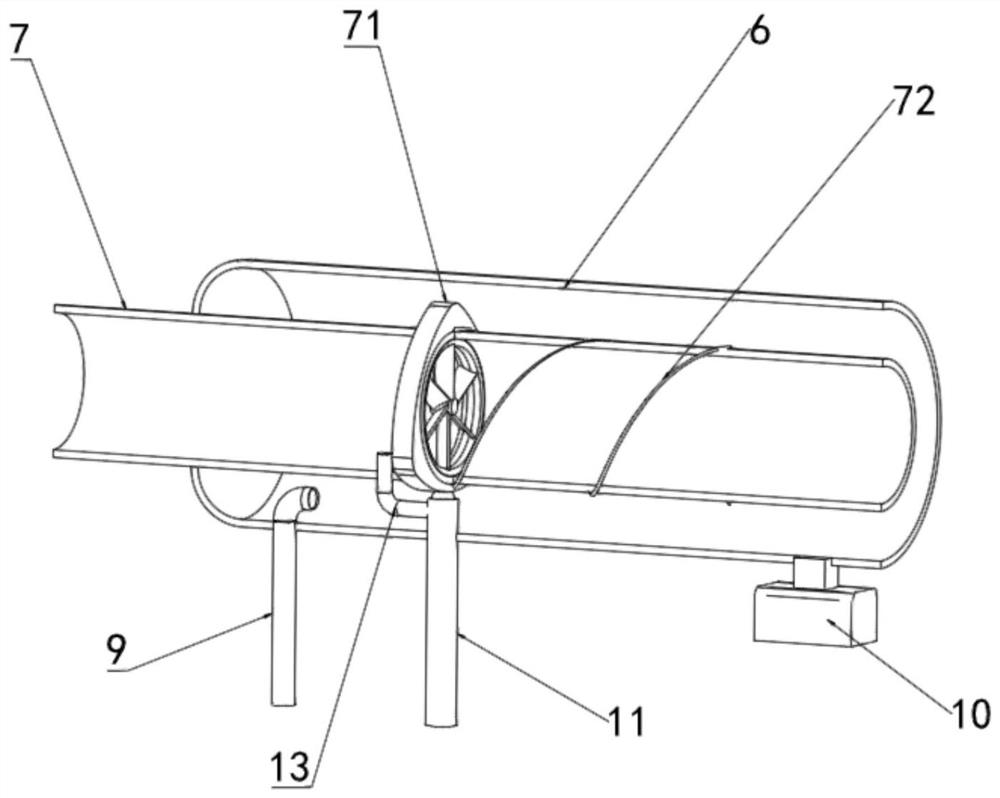

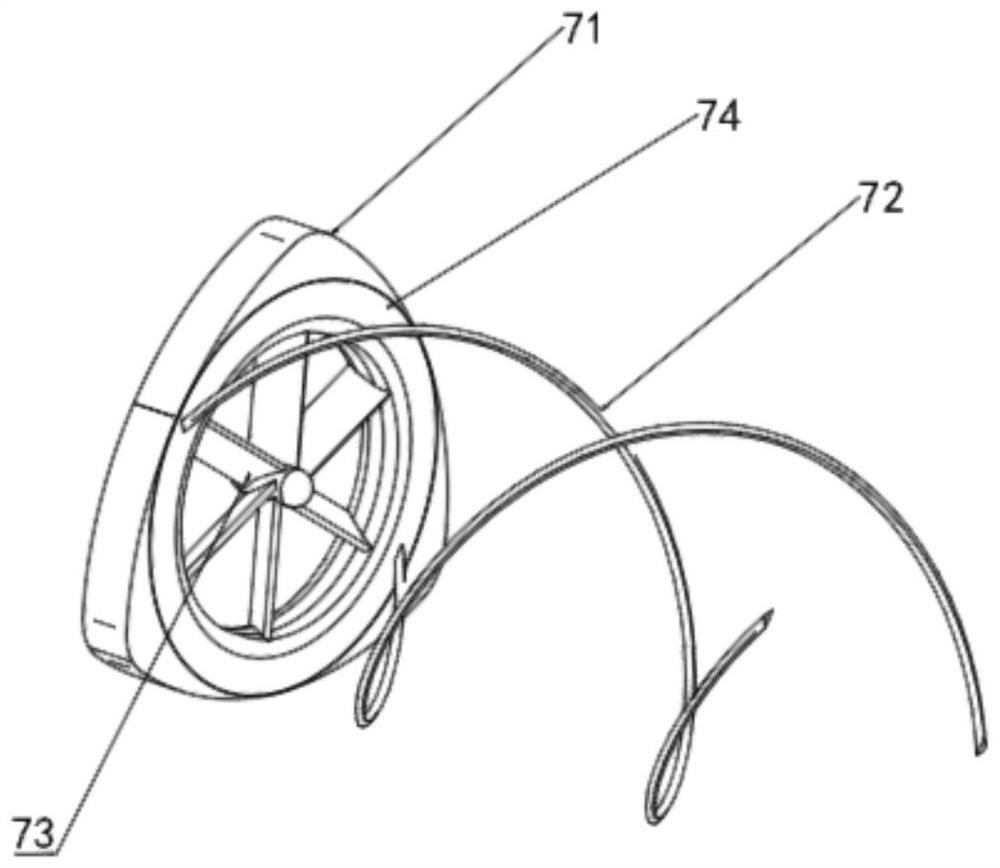

[0029] refer to Figure 1-7 , a flue gas denitration utilization device of a gas turbine waste heat boiler, comprising a heat exchanger 2, a urea hydrolysis device 8 and a denitration reactor 12, the air inlet of the heat exchanger 2 is connected with a flue gas intake pipe 1, and the The output port is connected with a decompression and desuperheating flue gas pipe 3, the other end of the decompression and desuperheating flue gas pipe 3 is provided with a pneumatic regulating valve 4, and the output end of the pneumatic regulating valve 4 is connected with a dilution air duct 7. The other end is connected with the ammonia gas input end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com