Temperature-sensitive debonding wet tissue adhesion hydrogel and preparation method thereof

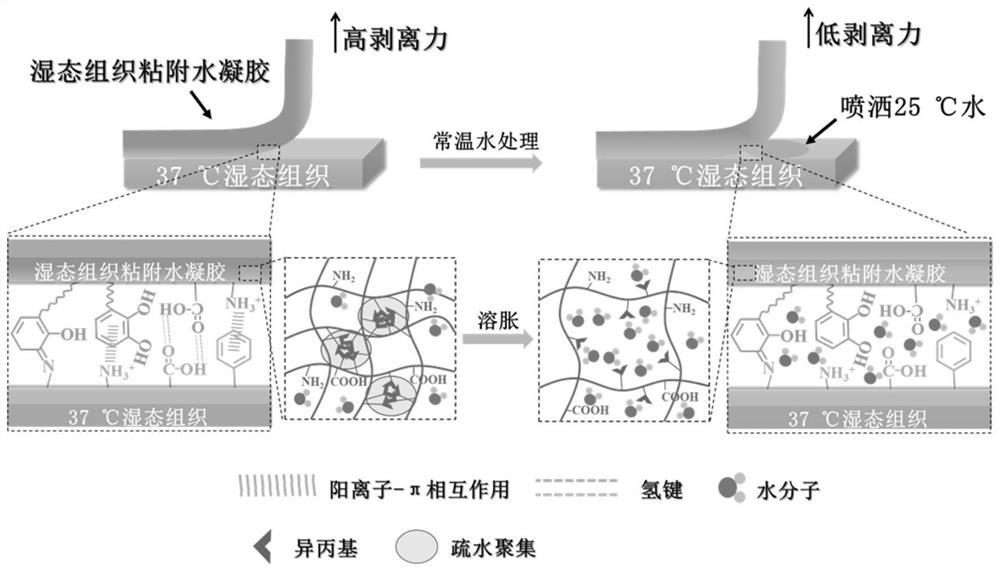

A hydrogel and debonding technology, which is applied in the directions of pharmaceutical formulation, surgery, drug delivery, etc., can solve problems such as difficult and difficult to peel off practical applications, and achieve the effect of short molding time, simple process and simple debonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a temperature-sensitive and debonded wet tissue-adhering hydrogel, comprising the following steps:

[0030] 1. Dissolve 1.4g N-isopropylacrylamide, 0.6g acrylamide, 0.02g aminoethyl starch and 0.05g calcium chloride in 1g water;

[0031] 2. Add 0.02g urushiol, 0.002g crosslinking agent N,N'-methylenebisacrylamide and 0.006g photoinitiator 2,4,6-(trimethylbenzoyl) to the solution obtained in step 1 Diphenylphosphine oxide, stir to dissolve;

[0032] 3. Pour the solution obtained in step 2 into a polytetrafluoroethylene mold, and cure under 365 nm ultraviolet light for 60 minutes to obtain a temperature-sensitive and debonded tissue-adhesive hydrogel.

Embodiment 2

[0034] A preparation method of a temperature-sensitive and debonded wet tissue-adhering hydrogel, comprising the following steps:

[0035] 1. Dissolve 1.4g N-isopropylacrylamide, 0.6g acrylamide, 0.02g gelatin and 0.05g calcium chloride in 1g water;

[0036] 2. Add 0.02g urushiol, 0.004g crosslinking agent N,N'-methylenebisacrylamide and 0.008g photoinitiator 2,4,6-(trimethylbenzoyl) to the solution obtained in step 1 Diphenylphosphine oxide, stir to dissolve;

[0037] 3. Pour the solution obtained in step 2 into a mold, and cure under 365 nm ultraviolet light for 60 minutes to obtain a temperature-sensitive debonded tissue-adhesive hydrogel.

Embodiment 3

[0039] A preparation method of a temperature-sensitive and debonded wet tissue-adhering hydrogel, comprising the following steps:

[0040] 1. Dissolve 1.6g N-isopropylacrylamide, 0.4g acrylamide, 0.02g aminoethyl starch and 0.01g calcium chloride in 1g water;

[0041] 2. Add 0.02g urushiol, 0.004g crosslinking agent N,N'-methylenebisacrylamide and 0.008g photoinitiator 2,4,6-(trimethylbenzoyl) to the solution obtained in step 1 Diphenylphosphine oxide, stir to dissolve;

[0042] 3. Pour the solution obtained in step 2 into a mold, and cure under 365 nm ultraviolet light for 120 minutes to obtain a temperature-sensitive and debonded tissue-adhesive hydrogel.

PUM

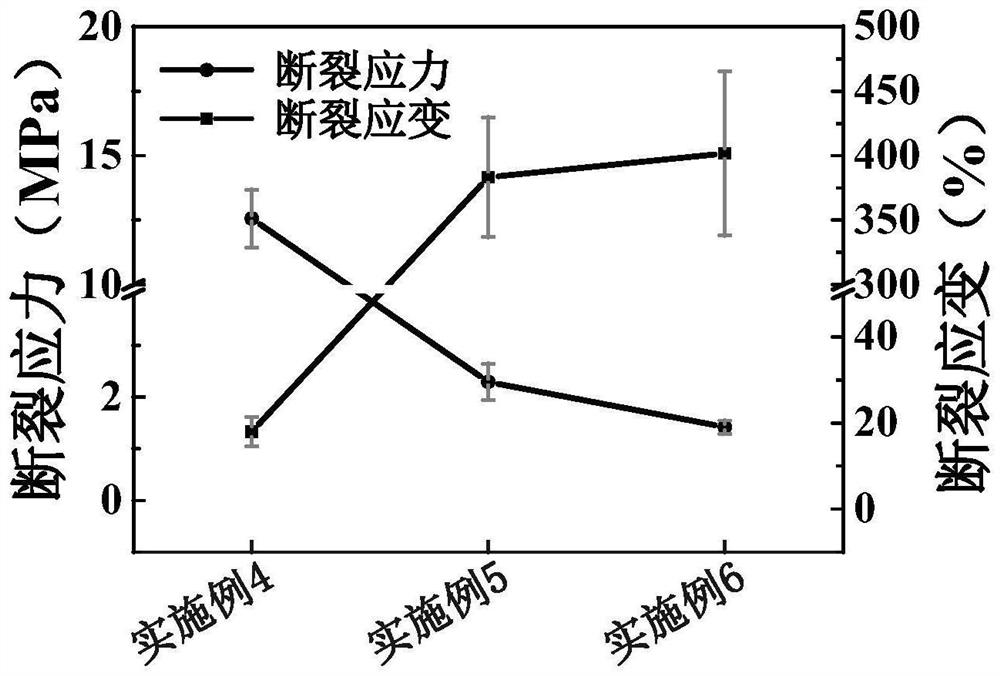

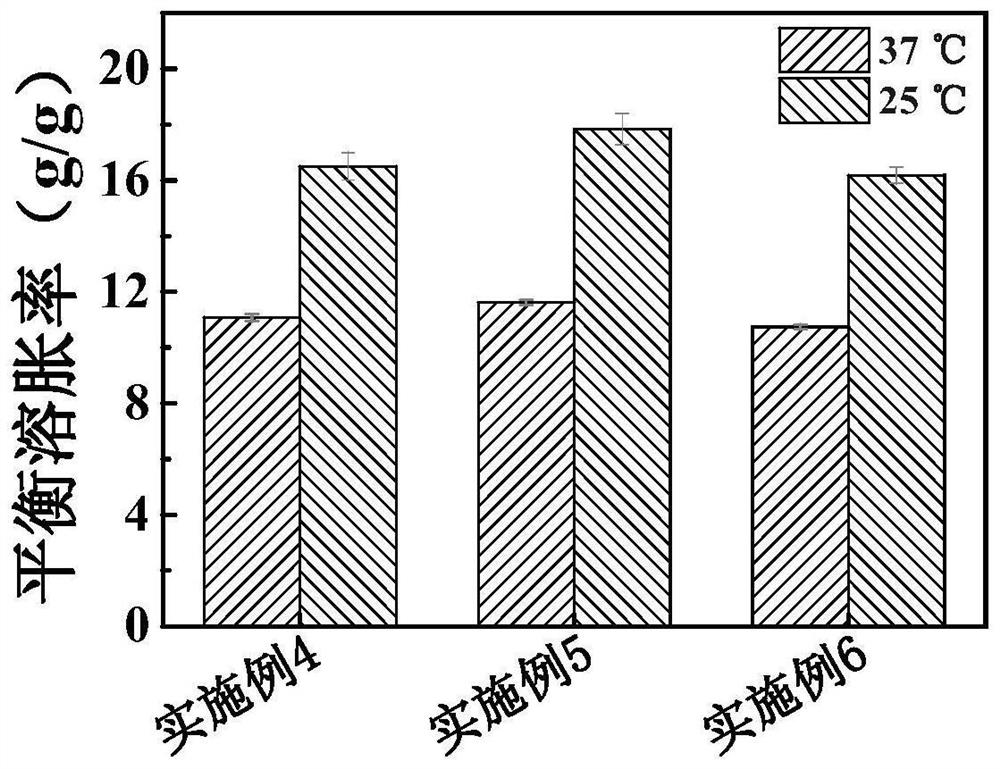

| Property | Measurement | Unit |

|---|---|---|

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com