Surface coating capable of degrading magnesium and magnesium alloy and preparation method of surface coating

A surface coating and magnesium alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of lack of coating thickness, coverage and interface bonding strength, long time, and inability to form, and it is difficult to control and produce uniformity. The process is simple and the effect of improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

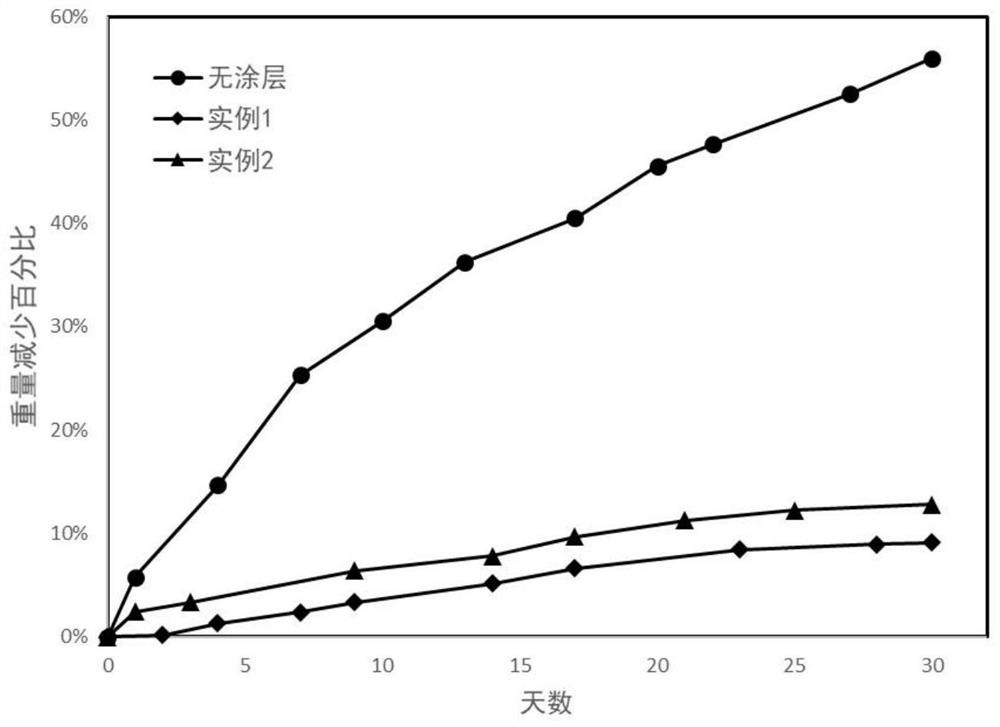

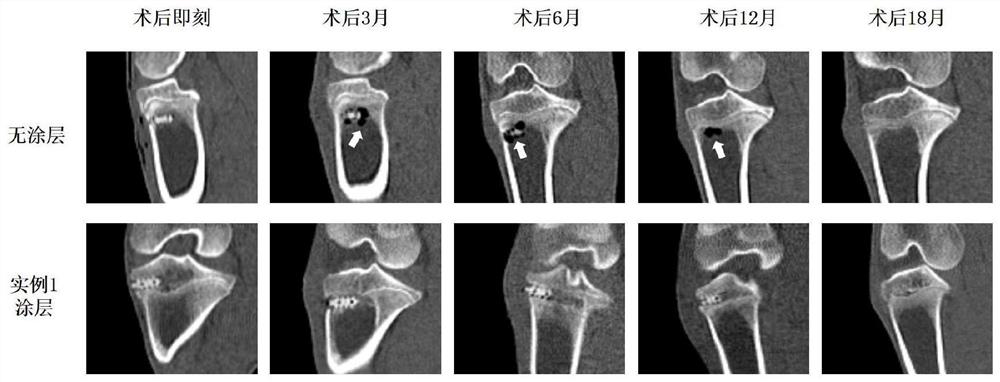

Embodiment 1

[0030] Prepare a controllable degradable coating on the surface of AZ31 magnesium alloy rods, the specific steps are as follows:

[0031] 1) First, AZ31 magnesium alloy is made into a Φ3×10mm sample, polished with 800#, 1200#, 2000# sandpaper in turn, ultrasonically cleaned in anhydrous acetone for 5 minutes to remove the surface oil, and dried after cleaning;

[0032] 2) Prepare a solution containing 0.25mol / L magnesium nitrate and 0.25mol / L sodium dihydrogen phosphate, adjust the pH of the solution to 3.5 with dilute nitric acid, and heat it in a water bath to 75°C;

[0033] 3) Put the AZ31 magnesium alloy sample into the heated solution, soak and react for 60 minutes, then take it out and rinse it with deionized water, and dry it to obtain the AZ31 magnesium alloy sample with a magnesium phosphate conversion layer;

[0034] 4) Prepare a solution containing 0.25mol / L calcium citrate and 0.25mol / L sodium dihydrogen phosphate, and use sodium hydroxide to adjust the pH to 9.5; ...

Embodiment 2

[0038] Prepare a controllable degradable coating on the surface of AZ31 magnesium alloy rods, the specific steps are as follows:

[0039]1) First, AZ31 magnesium alloy is made into a Φ3×10mm sample, polished with 800#, 1200#, 2000# sandpaper in turn, ultrasonically cleaned in anhydrous acetone for 5 minutes to remove the surface oil, and dried after cleaning;

[0040] 2) Prepare a solution containing 0.5 mol / L magnesium sulfate and 0.5 mol / L potassium dihydrogen phosphate, adjust the pH of the solution to 2.5 with dilute sulfuric acid, and heat it in a water bath to 60°C;

[0041] 3) Put the AZ31 magnesium alloy sample into the heated solution, soak and react for 120 minutes, then take it out and rinse it with deionized water, and dry it to obtain the AZ31 magnesium alloy sample with a magnesium phosphate conversion layer;

[0042] 4) Prepare a solution containing 0.15mol / L calcium EDTA-Ca and 0.15mol / L potassium dihydrogen phosphate, and adjust the pH to 9.0 with potassium hy...

Embodiment 3

[0046] Prepare a controllable degradable coating on the surface of ZK60 magnesium alloy rods, the specific steps are as follows:

[0047] 1) First, make a Φ3×10mm sample of ZK60 magnesium alloy, polish it with 800#, 1200#, 2000# sandpaper in turn, and ultrasonically clean it in anhydrous acetone for 5 minutes to remove the surface oil, and then dry it after cleaning;

[0048] 2) Prepare a solution containing 0.25 mol / L magnesium dihydrogen phosphate, adjust the pH of the solution to 3.0 with phosphoric acid, and heat to 70°C in a water bath;

[0049] 3) Put the ZK60 magnesium alloy sample into the heated solution, soak and react for 45 minutes, then take it out and rinse it with deionized water, and dry it to obtain a K60 magnesium alloy sample with a magnesium phosphate conversion layer;

[0050] 4) Prepare a solution containing 0.10 mol / L calcium citrate and 0.10 mol / L sodium dihydrogen phosphate, and use sodium hydroxide to adjust the pH to 9.0;

[0051] 5) Put the K60 mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com