Tin oxide-based hydrogen sensing material based on rare earth element doping and precious metal modification as well as preparation method and application of tin oxide-based hydrogen sensing material

A rare earth element, sensing material technology, applied in tin oxide, material resistance, analytical materials, etc., can solve the problems of long response time and recovery time, poor hydrogen selectivity, complex preparation process, etc., to promote electron transfer and low detection. Limit, improve the effect of sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

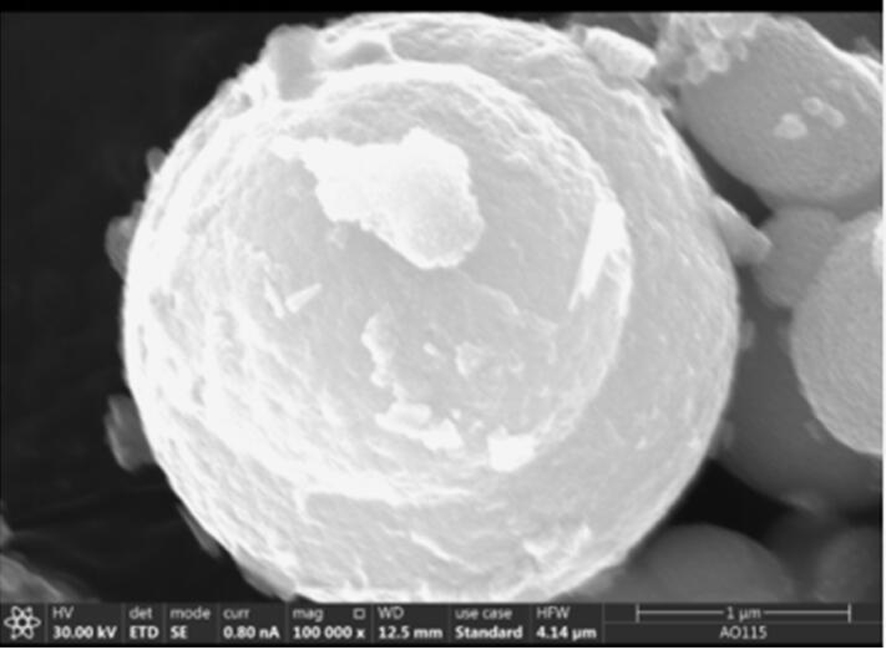

[0033] Comparative example 2: The only difference between this comparative example and Example 2 is that excess sodium hydroxide is added. The add-on of sodium hydroxide is 5g. Due to the excessive addition of sodium hydroxide, the pH value of the solution is too high, resulting in the smaller size of the prepared tin oxide microspheres, with a diameter of 50nm; the hydrogen sensor device obtained in this comparative example, at a working temperature of 200 ° C, the detection range is 125ppb-5ppm, the response time is 30s, the recovery time is 48s, and the response value to the hydrogen concentration of 5ppm is 9. Significant difference with the effect in Example 2.

[0034] Comparative example 3: The only difference between this comparative example and Example 3 is that no chloroauric acid solution is added. The hydrogen sensor device obtained in this comparative example has a detection range of 125ppb-5ppm at a working temperature of 250°C, a response time of 29s, a recove...

Embodiment 2

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com