Chromium-free passivation method for zinc powder

A technology of chromium-free passivation and zinc powder, applied in metal material coating technology, photovoltaic power generation, etc., can solve the problem of losing anti-rust pigments, etc., achieve good stability, unaffected electrochemical performance, and low environmental equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

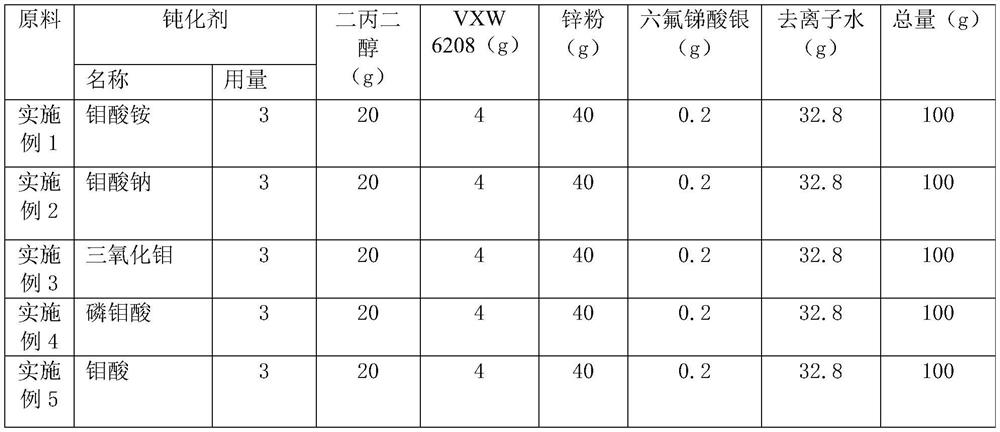

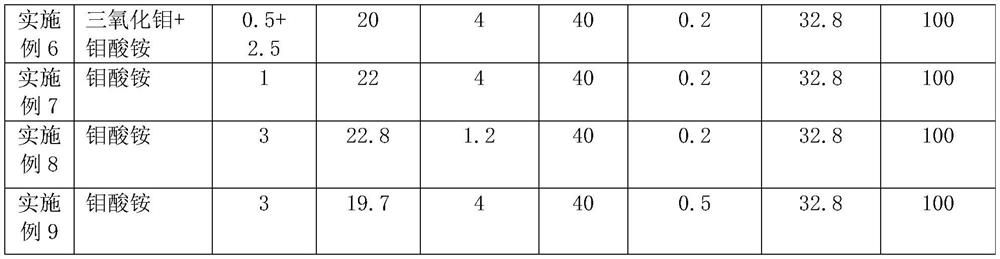

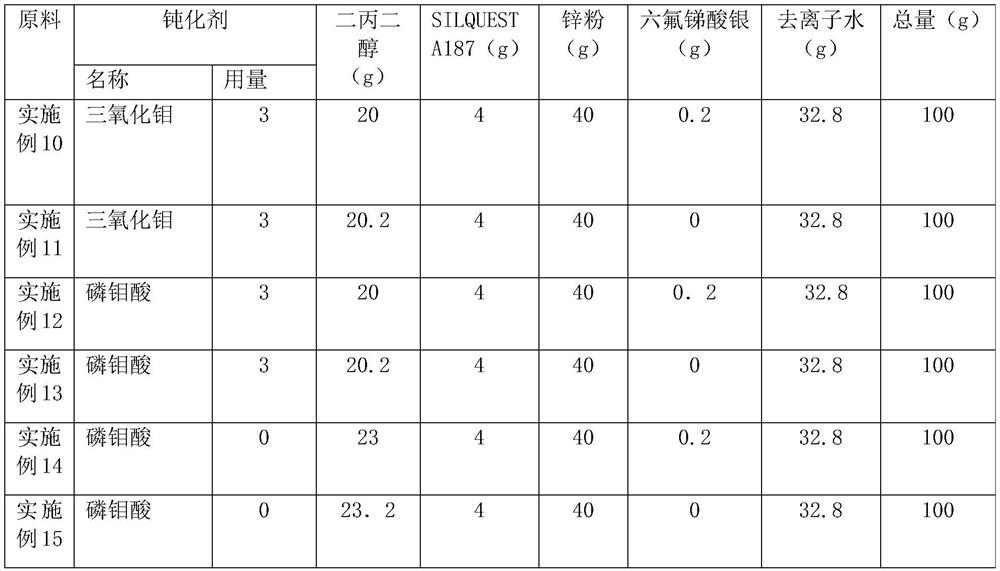

Embodiment 1-15

[0045] Embodiment 1-15 relates to a kind of zinc powder passivation method, specifically comprises the steps:

[0046] S1. Add the general dispersing aid for water and oil into the water-soluble organic solvent, and stir evenly;

[0047] S2. Add zinc powder to the medium mixed evenly in step S1, and stir evenly;

[0048] S3. Add deionized water, molybdenum-containing compound, and silver hexafluoroantimonate into the uniformly mixed medium in step S2, and stir uniformly to prepare a passivated water-based zinc paste.

[0049] Wherein, after uniform stirring in step S2, in order to ensure uniform mixing, secondary stirring is performed for 20-90 minutes.

[0050] After the stirring is uniform in step S3, in order to ensure uniform mixing, secondary stirring is performed for 20-90 minutes. An aqueous zinc paste was prepared.

[0051]The substances and process parameters involved in the zinc powder passivation method of Examples 1-15 of the present invention are shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com