Beneficiation separation method for copper-zinc sulfide ore with high copper-zinc ratio

A copper-zinc sulfide and separation method technology, applied in chemical instruments and methods, magnetic separation, solid separation and other directions, can solve the problems of high copper content in zinc concentrate, difficult magnetic separation process, low flotation separation efficiency, etc. Improve overall economic efficiency, improve product quality, and reduce the effect of drug types and dosages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

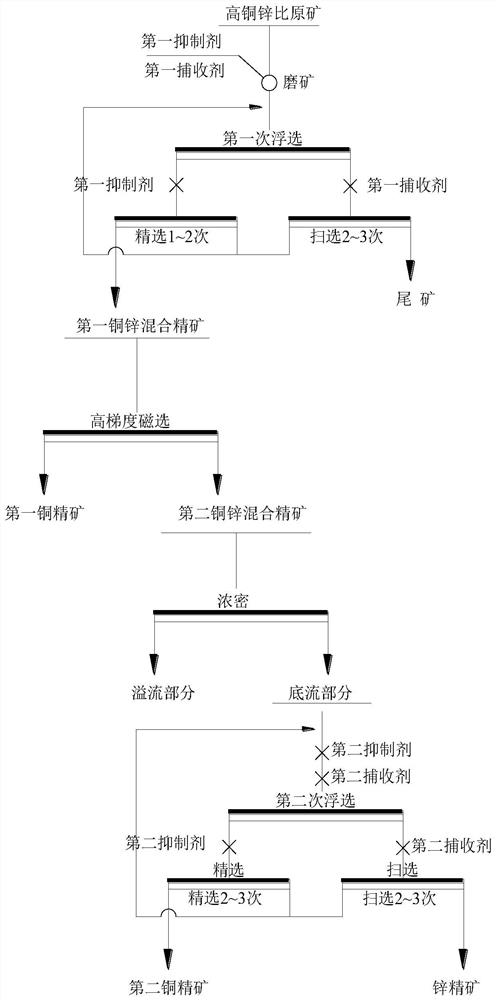

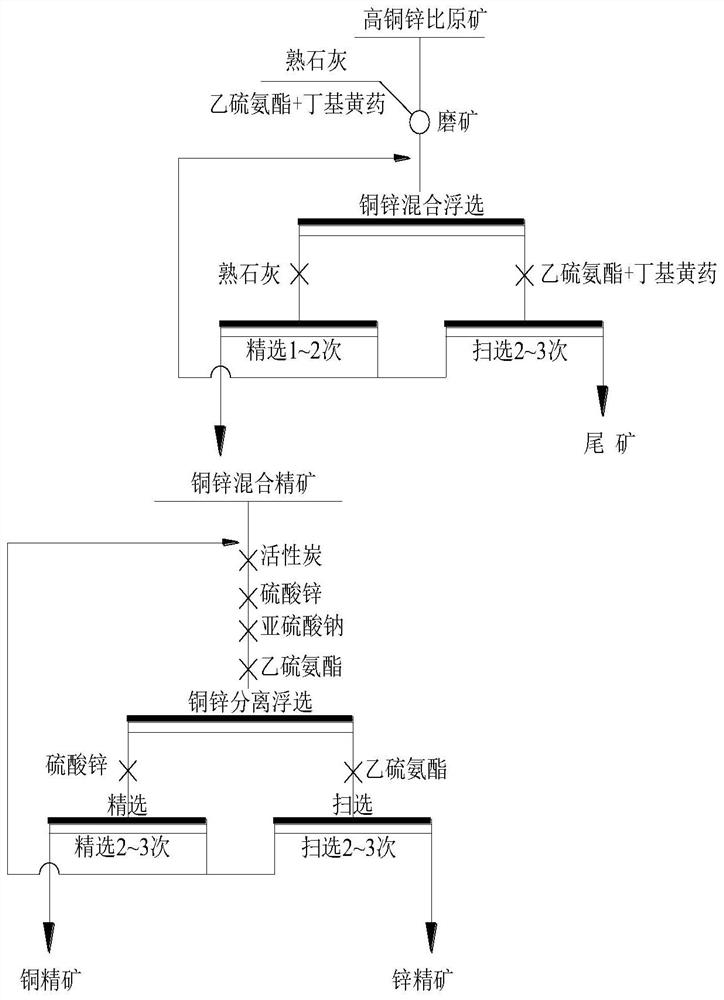

Method used

Image

Examples

Embodiment 1

[0033] Mineral beneficiation and separation of a high copper-zinc ratio copper-zinc ore in Qinghai

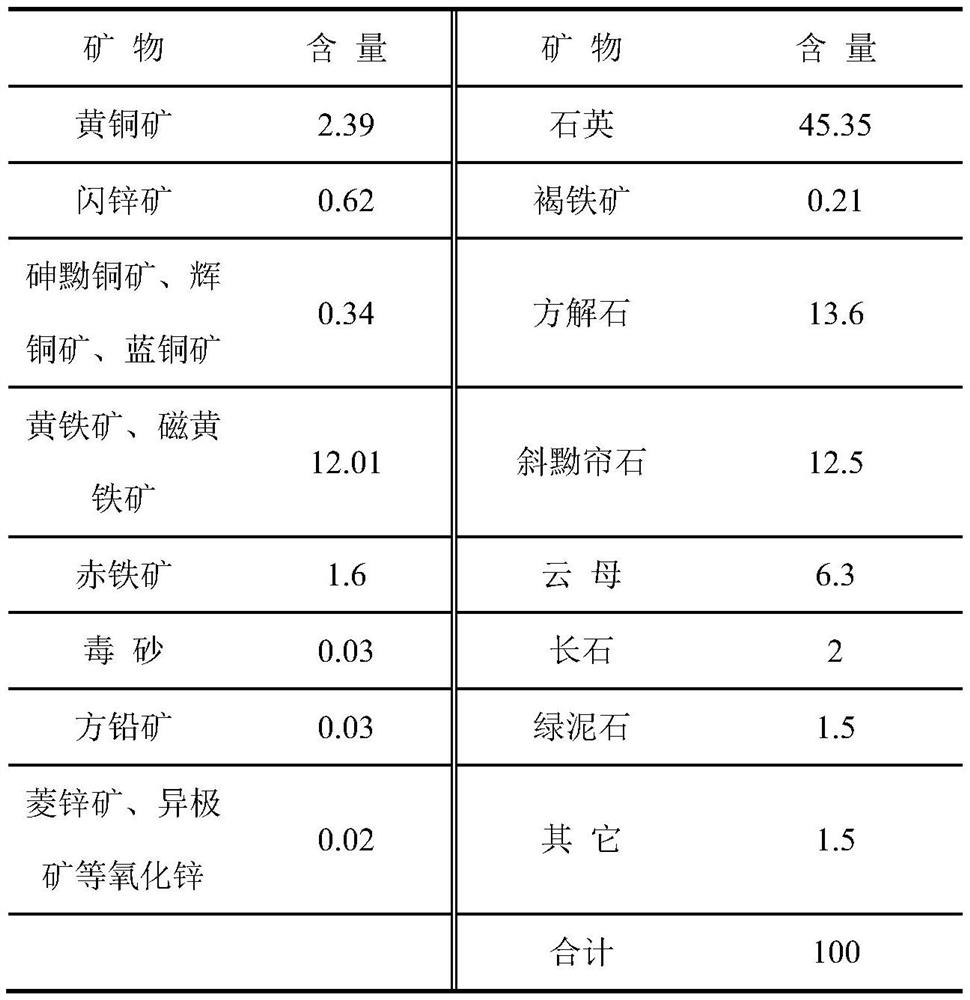

[0034] The raw ore produced by a copper-zinc sulfide mine in Qinghai contains Cu 1.25% and Zn 0.86%, and the copper-zinc element content ratio of the raw ore is 1.45. Through the analysis of copper-zinc phase and scanning electron microscope, it can be seen that the main metal minerals and sulfide minerals in the ore are , including pyrite, chalcopyrite, sphalerite, pyrrhotite, arsenite, chalcocite, azurite, hematite, etc. The gangue minerals are mainly quartz, and also contain some mica, calcite Aluminosilicate gangue minerals such as phyllozoite, feldspar, etc., the copper in the original ore is 79.22% copper in the primary sulfide ore, followed by secondary copper sulfide, with a distribution rate of 15.42%, zinc It mainly occurs in the form of primary zinc sulfide (zinc sulfide), with a distribution rate of 94.32%. After energy spectrum analysis, the zinc mineral Fe content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetic susceptibility | aaaaa | aaaaa |

| magnetic susceptibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com