Device for preparing high-length-consistency semiconductor laser wafer natural cleavage surface and use method thereof

A technology of natural cleavage and consistency, applied in the field of devices for preparing natural cleavage surfaces of semiconductor laser wafers with high length consistency, can solve the problems of expensive equipment, low efficiency, inconsistent length of natural cleavage surfaces, etc., and achieve consistent length Good performance, easy cleavage, time- and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

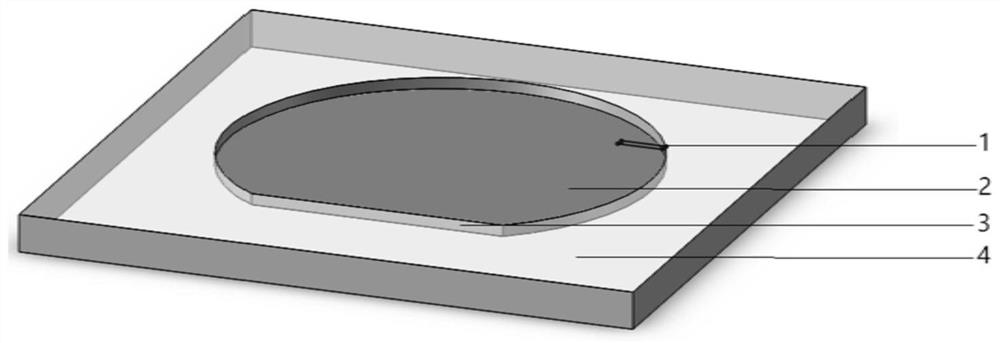

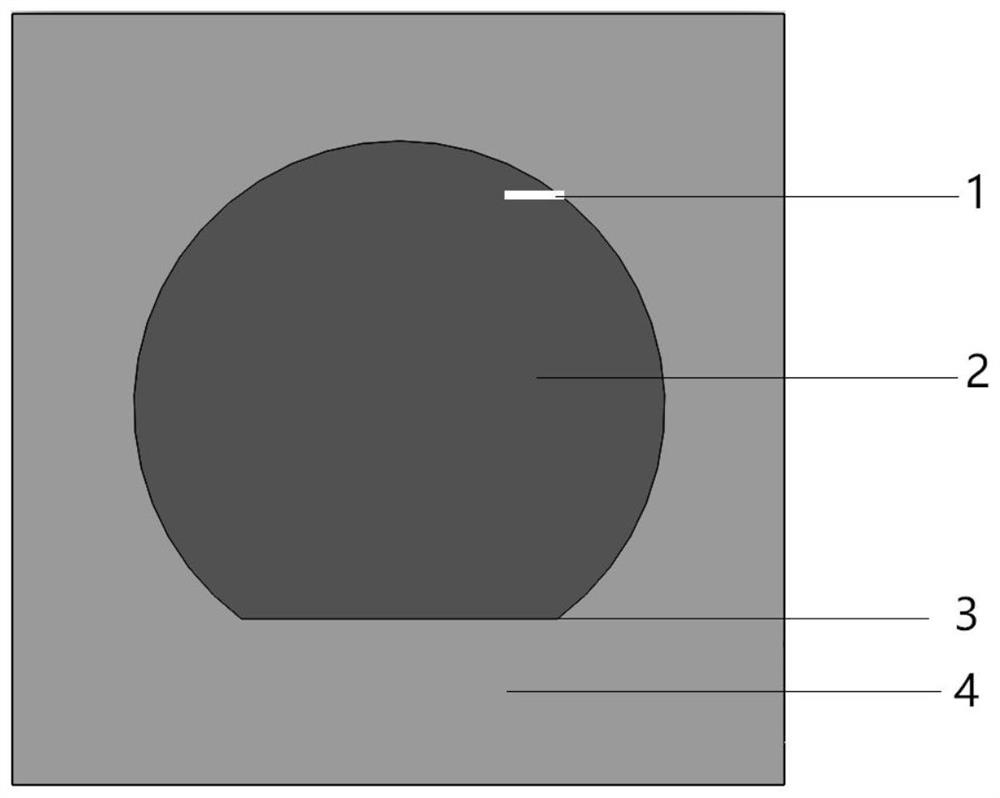

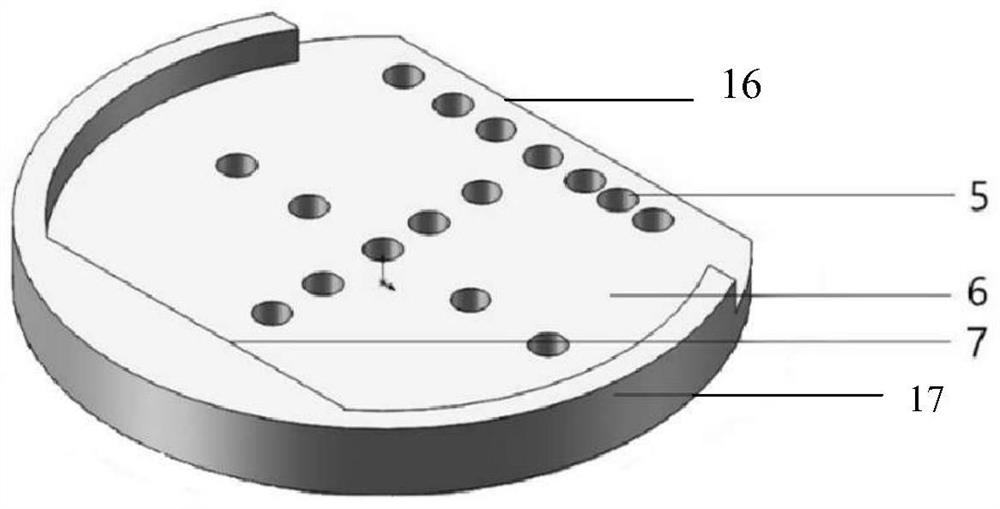

[0051] A device for preparing the natural cleavage surface of a semiconductor laser wafer with high length consistency, such as figure 1 , figure 2 and image 3 As shown, including the photolithography mask 4 and the vacuum fixing base 14,

[0052] The surface of the photolithography mask 4 is provided with a groove, and the groove is used to limit the wafer 8. The shape of the groove is the same as that of the wafer 8. The shape of the groove includes a limit flat edge 3 and a The limit flat edge 3 is an arc edge connected end to end, the limit flat edge 3 is used to limit the cutting surface 10 of the wafer, and the arc edge is used to limit the circumference of the wafer 8; the groove includes a light-transmitting area 1 and opaque area 2, the transparent area 1 is set at the edge of the groove, and the transparent area 1 is parallel to the limit flat edge 3, the transparent area 1 is used to form the transparent area 1 on the wafer 8 deep groove structures 12 with the ...

Embodiment 2

[0064] Based on the method for preparing the device for the natural cleavage surface of a semiconductor laser wafer with high length consistency provided in Embodiment 1, the method includes:

[0065] (1) Coating photoresist on the backside of the wafer 8; in step (1), the photoresist is a positive photoresist.

[0066] (2) After pre-baking, the wafer 8 is placed in the groove of the photolithography mask 4, the side coated with photoresist on the wafer 8 is in contact with the groove, and the cut surface 10 of the wafer is in contact with the groove. The limit flat edge 3 is in contact, and the circumference of the wafer 8 is in contact with the arc edge of the groove; the wafer 8 is limited by the groove to ensure that the exposure position remains consistent;

[0067] (3) Expose and develop the wafer 8; the processed wafer 8 is as follows Figure 4 As shown, one side of the wafer has a chamfer 9 of the wafer. In step (3), the photolithography mask 4 is irradiated and expo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com