Wire Equal Length Shearing Machine

A shearing machine and steel wire technology, applied in the field of mechanical processing, can solve problems such as low shearing efficiency, high labor intensity of workers, and poor product consistency, and achieve high shearing efficiency, meet mass production, and low processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

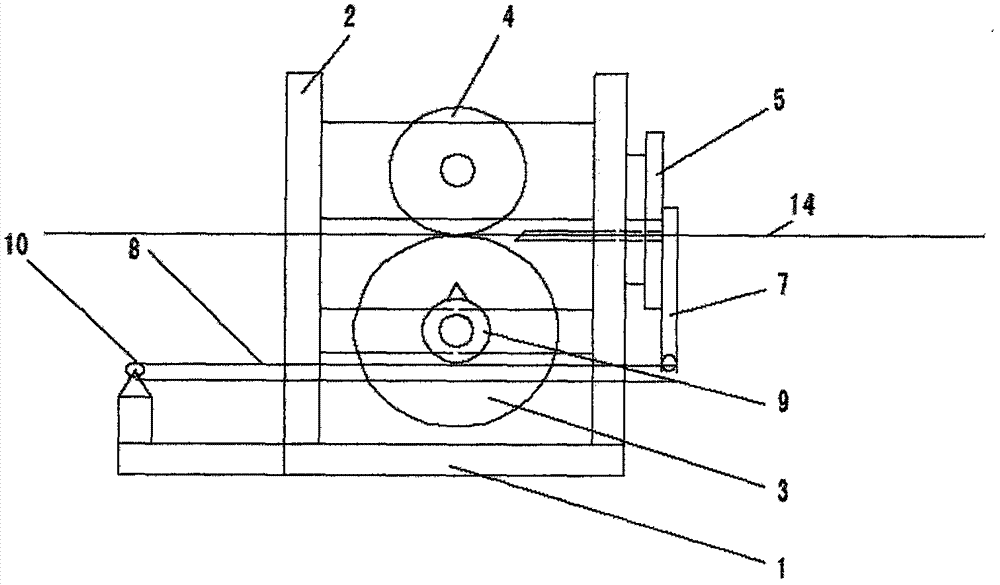

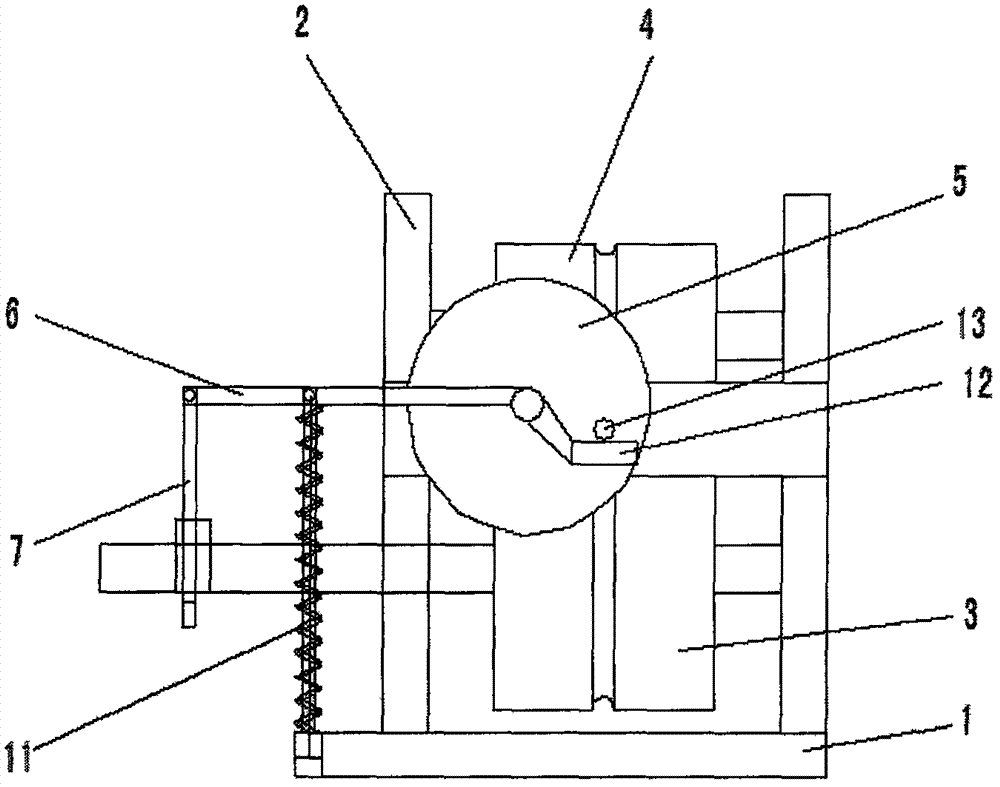

[0017] Steel wire equal length shearing machine of the present invention, as figure 1 , 2 As shown, it includes a base 1, a support frame 2, a lower roller 3, an upper pressure roller 4, a shear disc 5, a cutter bar 6, a vertical link 7, a horizontal link 8, a cam 9, a hinge point 10, a spring 11, Shear knife 12;

[0018] The support frame 2 is fixed on the base 1, and the support frame 2 is connected with two upper pressure rollers 4 and lower rollers 3 arranged up and down and parallel to the rotation plane through two horizontal shafts. The distance between the lower end of the outer ring of the upper roller 4 and the upper end of the outer ring of the lower roller 3 matches the outer diameter of the steel wire to be cut, so that the two are close to each other to form a steel wire clamping point; the upper end of the support frame 2 The front end of the pressure roller 4 and the lower roller 3 is fixed with a shear disc 5, and the shear disc 5 is horizontally provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com