Manufacturing method of coaxial cable

A manufacturing method and coaxial cable technology, applied in the direction of cable/conductor manufacturing, wire harness manufacturing, circuit manufacturing, etc., can solve the problems of large difference in length of waste materials, high labor intensity, inconvenient storage or transportation, etc., and achieve good consistency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with each accompanying drawing, the present invention is described in detail.

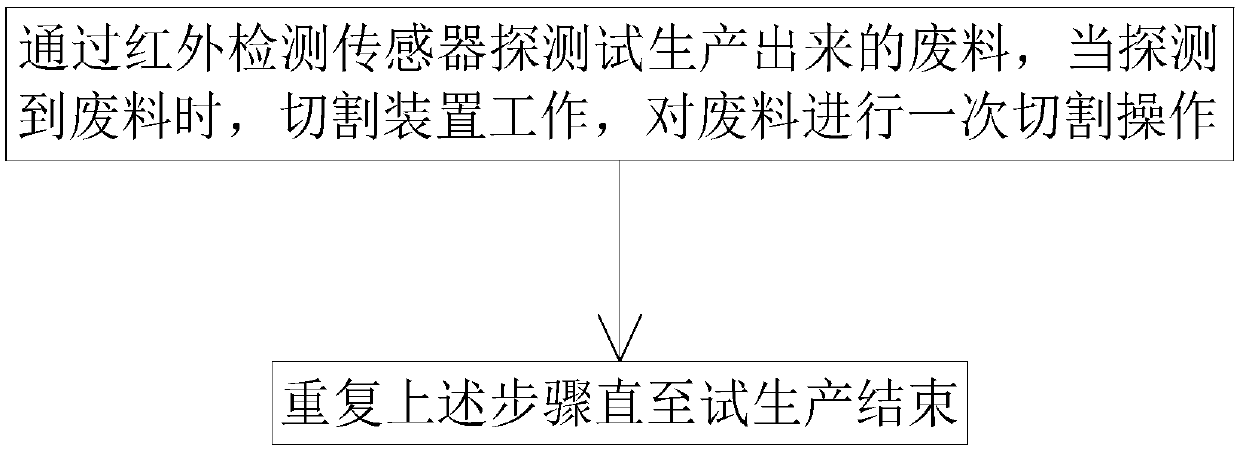

[0047] Such as figure 1 Shown, a kind of manufacturing method of coaxial cable comprises the following steps:

[0048] 1) The waste produced is detected by the infrared detection sensor. When the waste is detected, the cutting device works to perform a cutting operation on the waste;

[0049] 2) Repeat step 1) until the trial production is over.

[0050] This method can automatically detect the waste produced by the test by setting the infrared detection sensor, and when the waste is detected, the waste is automatically cut through the cutting device. The scrap length consistency is also better.

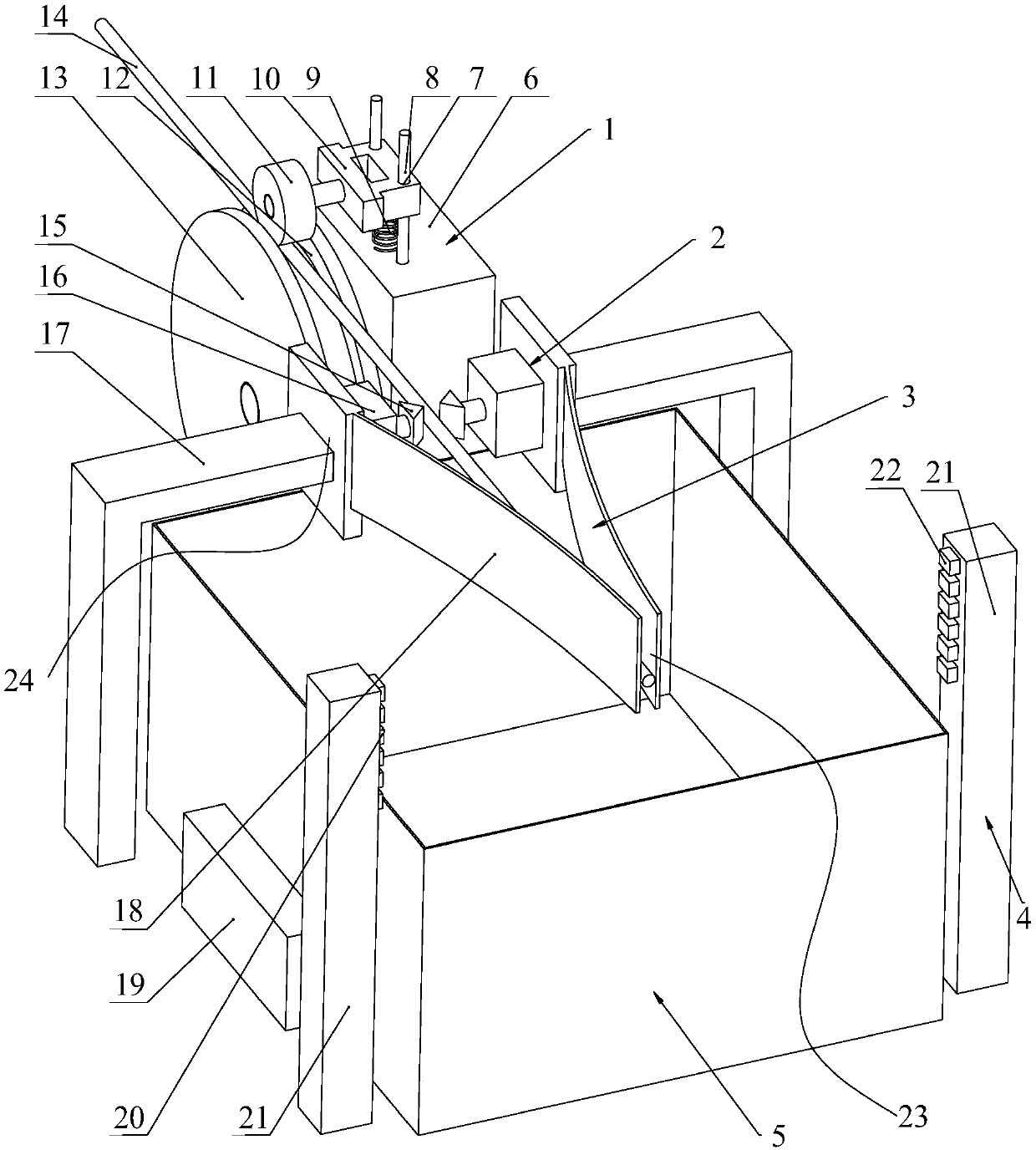

[0051] Such as figure 2 As shown, in the present embodiment, step 1) and step 2) are realized by automatic cutting equipment, and automatic cutting equipment comprises:

[0052] The first limit mechanism 1 is used for passing the waste material 14 and limiting the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com